Low protein and protein-free extended shelf life (esl) and shelf-stable aseptic liquid creamers and process of making thereof

A protein-free and protein-free technology, used in dairy products, food preparation, cream substitutes, etc., can solve the problems of physical instability of emulsions and decreased whitening ability, and achieve good physical and chemical stability, high whitening ability, and easy dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

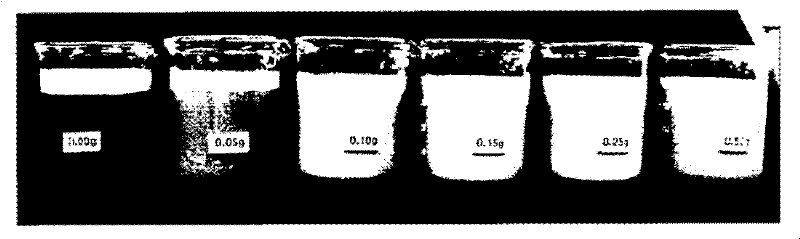

[0057] 500 g of sucrose were mixed together with 20 g of kappa-carrageenan, 40 g of iota-carrageenan and 200 g of a 10:1 MCC / CMC mixture. The dry mixture was added to 60 kg of hot water (65-70°C) at about 75°C under high speed stirring. In addition, 300 g of disodium hydrogen phosphate and 100 g of sodium tripolyphosphate were added to the vessel with constant stirring.

[0058] 1 kg of sucrose, 500 g of titanium dioxide, 50 g of sodium caseinate, 5 g of coloring agent and 500 g of flavoring agent were mixed together. The dry mixture was added to the hot water vessel with stirring, along with the aforementioned stabilizers. After mixing for 5-10 minutes, add 120 g with continuous stirring and 300g Under vigorous stirring, 4 kg of vegetable oil were added, followed by 25 kg of sucrose. The liquid is then UHT treated at 143° C. for 5 seconds, homogenized at 180 / 40 bar, cooled and filled under aseptic conditions with the coffee whitener into cans, jugs or bags.

[0059] Th...

Embodiment 2

[0064] A coffee whitener was prepared as described in Example 1, but using 15 g of sodium tripolyphosphate instead of 100 g of sodium tripolyphosphate.

[0065] The product was stored at room temperature for 9 months. No emulsions, phase separations, gelling, settling, and virtually no viscosity changes were observed during storage. However, adding this physically stable whitener to hot coffee resulted in an unacceptable visual appearance, with phase separation, emulsion destabilization, feathering and TiO 2 settlement.

[0066] The mouthfeel of the coffee with added coffee whitener was judged by 6 untrained panelists, all found the product to be of good quality and good aroma, no off-taste or off-flavor, but unacceptable graininess (sandy) of).

Embodiment 3

[0068] A coffee whitener was prepared as described in Example 1, but using 1300 g of sodium tripolyphosphate instead of 100 g of sodium tripolyphosphate.

[0069] The product was stored at room temperature for 9 months. No emulsions, phase separations, gelling, settling, and virtually no viscosity changes were observed during storage. However, adding this physically stable whitener to hot coffee resulted in an unacceptable visual appearance with phase separation, emulsion destabilization, feathering and TiO2 in the whitened coffee. 2 settlement.

[0070] The mouthfeel of the coffee with added coffee whitener was judged by 6 untrained panelists, all found the product to be of good quality but with an unacceptable taste (bitterness) and also an unacceptable visual appearance (some flocculation occurred ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com