Self-priming pump capable of applying fertilizer

A self-priming pump and pump body technology, applied in the field of liquid conveying equipment, can solve the problems of inconvenient use, long self-priming time, and small exhaust capacity, and achieve the effects of convenient use, short self-priming time and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

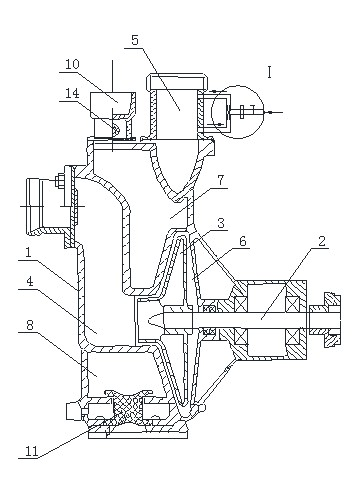

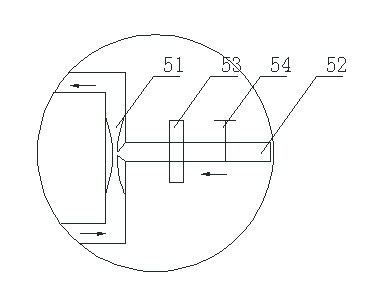

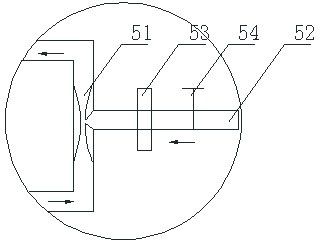

[0013] Such as figure 1 and figure 2 As shown, the present invention provides a fertilizing self-priming pump, which includes a pump body 1, a pump shaft 2 and an impeller 3, wherein the pump body 1 is provided with a water inlet chamber 4, a water outlet chamber 5, an impeller working chamber 6, and a water filling chamber. chamber 7 and exhaust chamber 8, the water inlet chamber 4 communicates with the water outlet chamber 5 through the impeller working chamber 6, the impeller 3 is installed on the pump shaft 2 and is located in the impeller working chamber 6, and the water adding chamber 7 communicates with the water outlet chamber 5 through a hole, The mouth 10 of the water filling chamber 7 is provided with a one-way valve 15; the exhaust chamber 8 communicates with the impeller working chamber 6, and the mouth of the exhaust chamber 6 is provided with a backflow stop valve 11, and the pump body 1 is also provided with a drain valve. The water discharge channel communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com