Method for detecting prestress construction quality of anchoring engineering

A construction quality and prestressing technology, which is applied in basic structure engineering, earthwork drilling, bolt installation, etc., can solve problems such as lack of technical means and methods, and effective detection has not yet been carried out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] For the existing anchoring project that the length of the steel strand used for tensioning meets the required length of tensioning, the method for quality detection of the anchoring project of the present invention comprises the following steps:

[0063] Step a: Install the tensioning device using the existing anchor cable tensioning test installation steps:

[0064] a 1 1. Place the clip limiting plate on the working anchor of the existing anchoring project, pass the remaining steel strands of the existing anchoring project through the jack, and place the bottom of the jack on the clip limiting plate;

[0065] a 2. Install the working anchor on the top of the jack, pass the remaining steel strand through the tool anchor, and then insert a tool clip into the tool anchor, and tighten the remaining steel strand;

[0066] Step b: Conduct a pull test:

[0067] b 1 , applying an initial load, so that the tension devices are tightly connected;

[0068] b 2 1. Slowly app...

Embodiment 2

[0071] For the existing anchoring project whose steel strands used for tension detection have been cut and cannot meet the required length of tensioning, it is necessary to install the existing anchoring project quality detection device of the present invention and then adopt the detection method of the present invention method to detect.

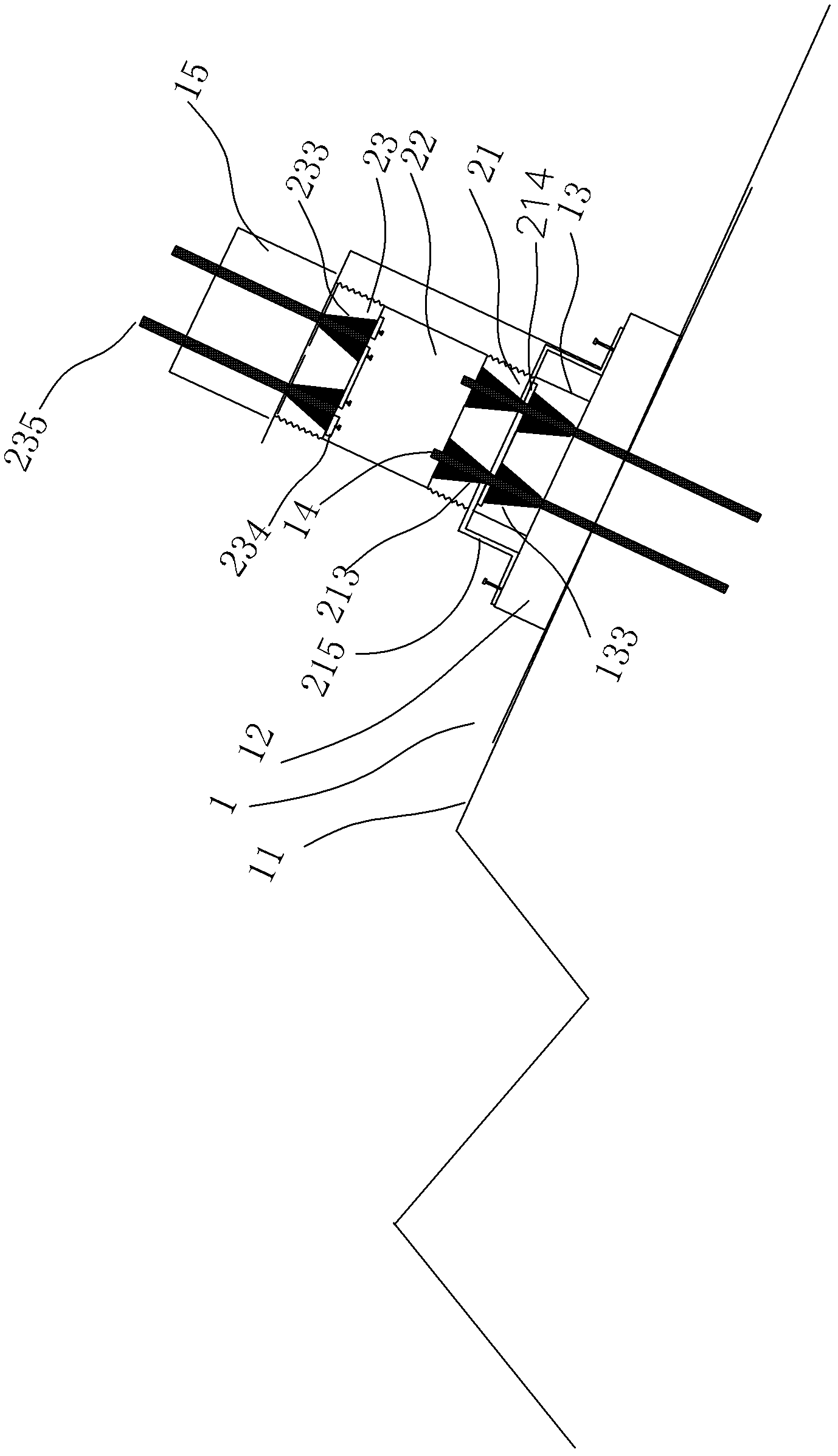

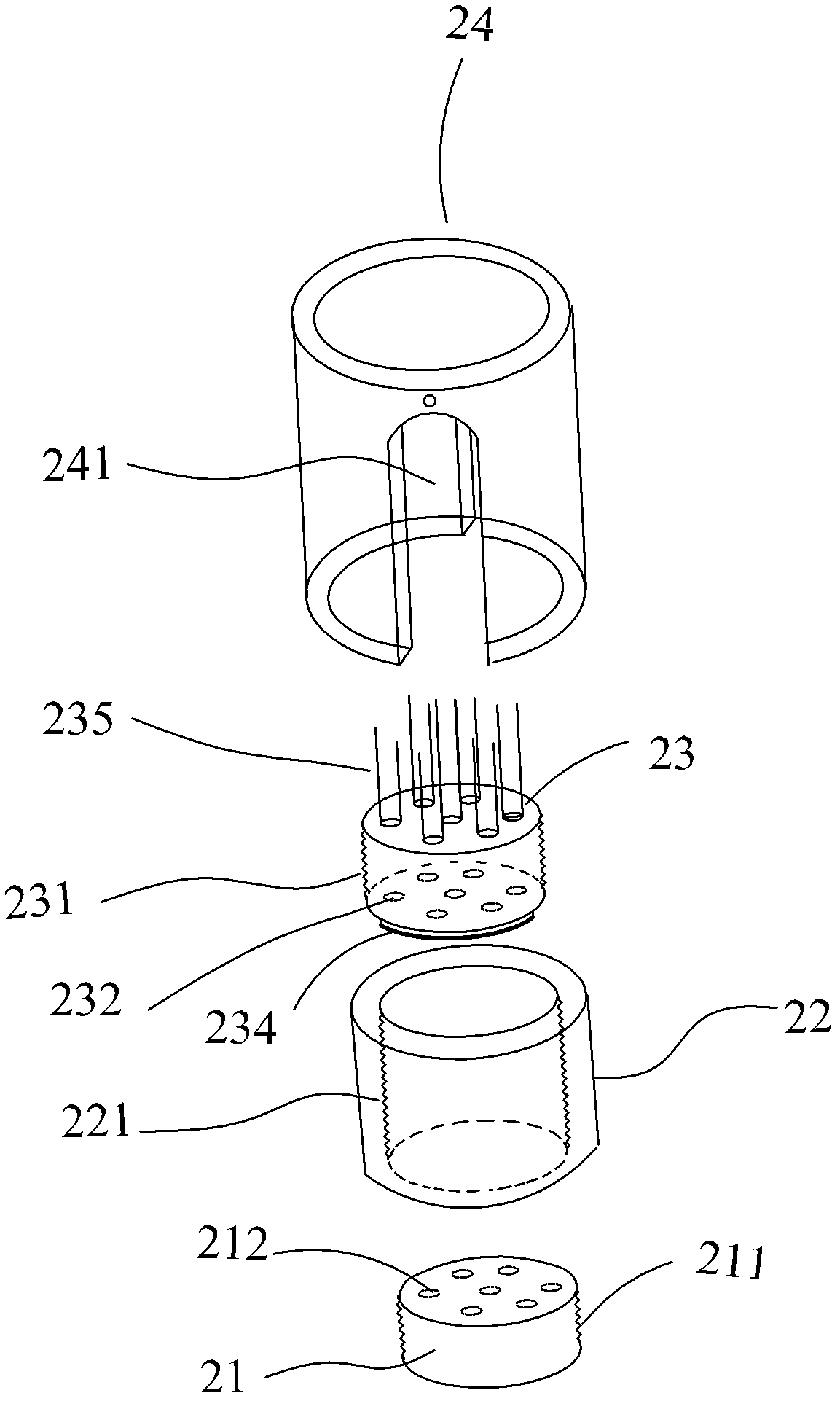

[0072] Such as figure 1 , 2 As shown, the device for quality inspection of existing anchoring projects according to the present invention includes three parts: a connecting part, a supporting part and a limiting part, and each part will be described in detail in conjunction with each view below.

[0073] The first part: the connecting part, including: the first tool anchor 21 , the second tool anchor 23 and the connecting sleeve 22 .

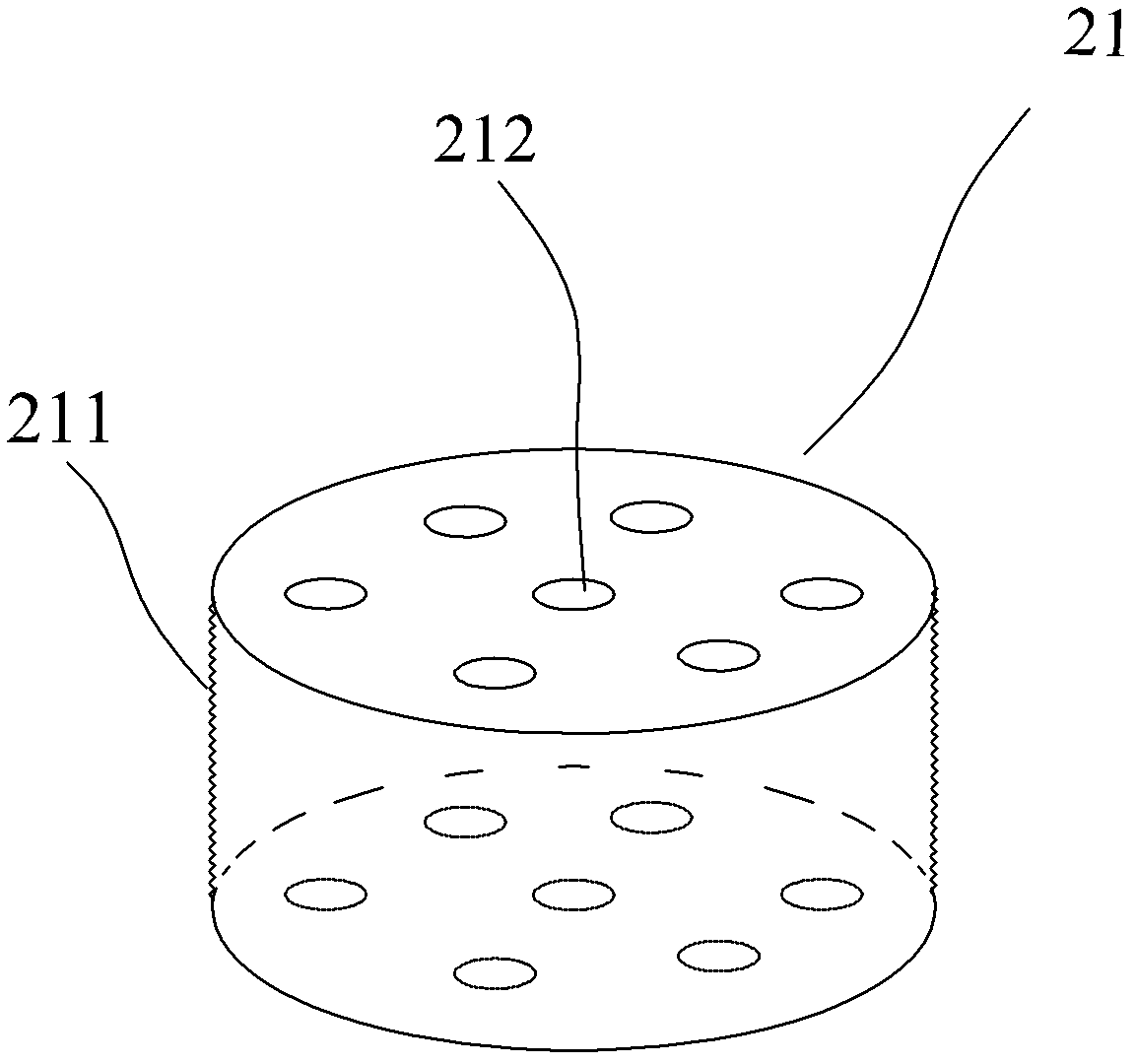

[0074] Such as figure 1 , figure 2 , image 3 As shown, the first tool anchor 21 is a cylindrical plate whose size and shape are basically the same as those of the working anchor 13 in the existing anch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com