Improved buttonholing machine tool

A buttonhole machine and buttonhole technology, applied in the direction of cloth pressing mechanism, sewing machine components, sewing machine control devices, etc., can solve the problems of difficult adjustment, extremely high requirements for assemblers, complex structure of rotating parts, etc. The effect of reducing the difficulty of debugging, reducing assembly requirements and debugging difficulty, and improving the efficiency of assembly and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

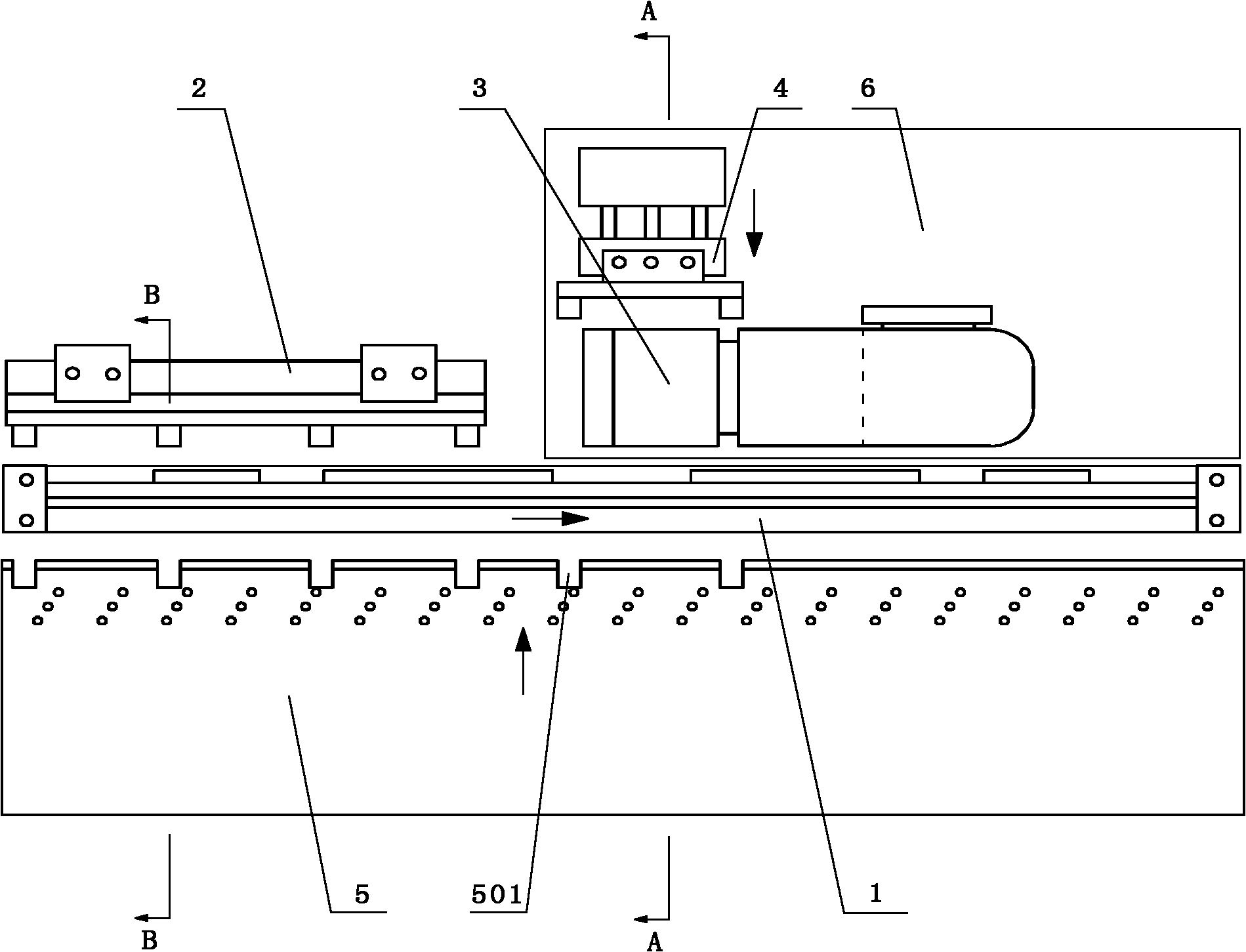

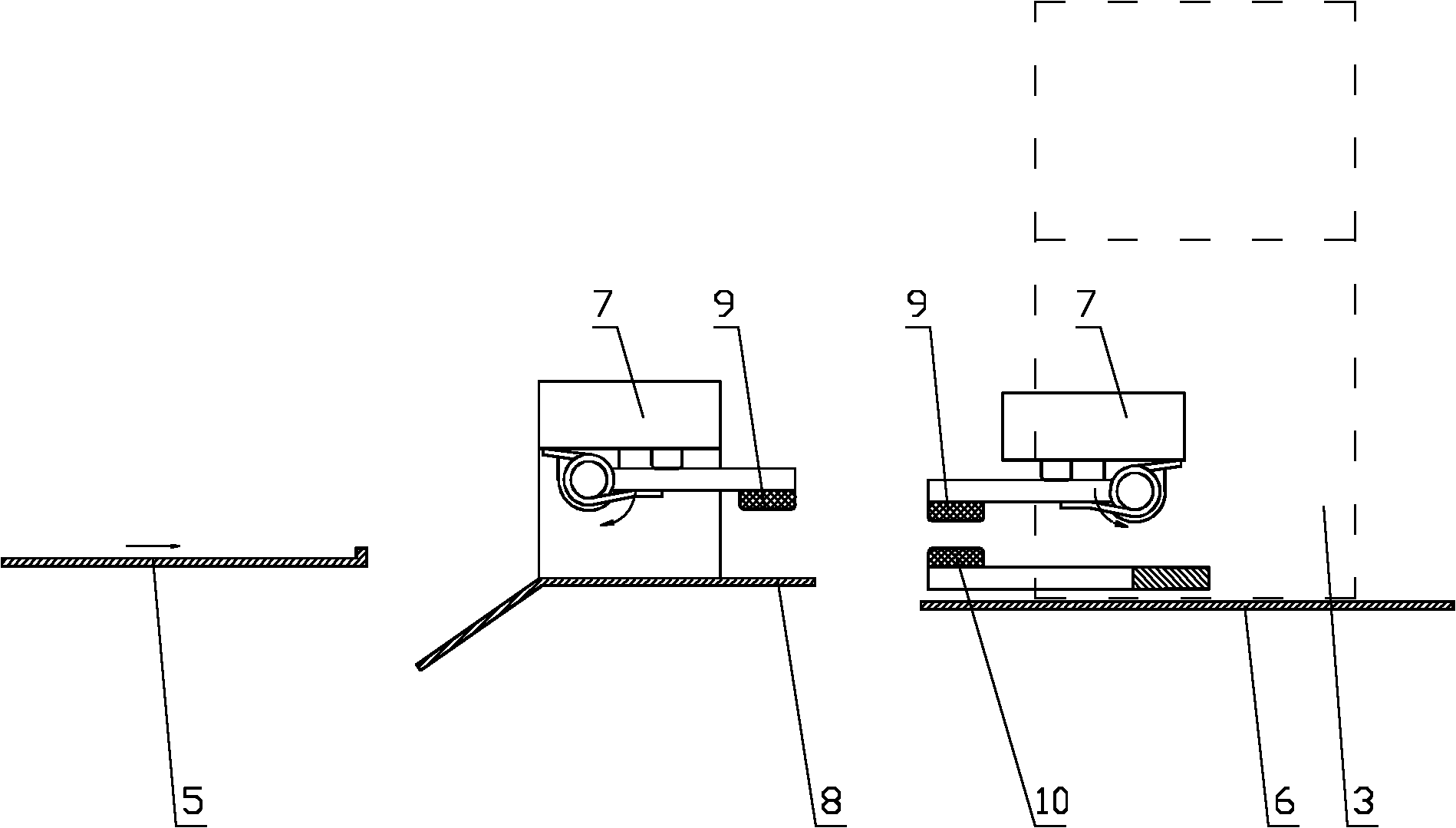

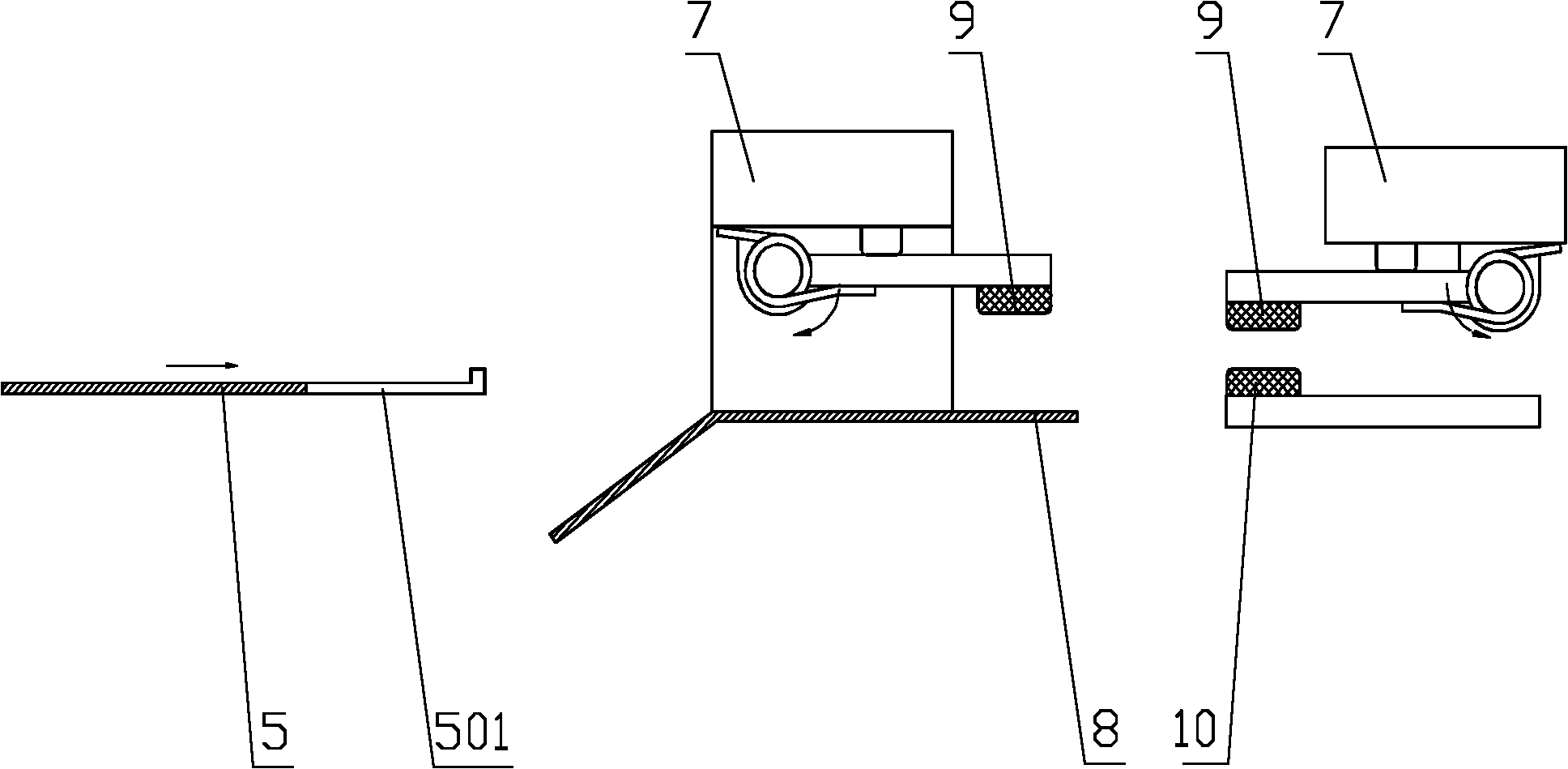

[0039] The present invention will be further described below in conjunction with accompanying drawing, and the arrow direction in the figure is the action direction of each moving part.

[0040] figure 1 Among them, the shirt placket buttonhole buttonhole machine tool includes a horizontally arranged rectangular feeding plate 5 and a pressing and feeding assembly 1 located on the rear side of the pressing and feeding assembly 1. The buttonhole machine 3, the buttonhole machine 3 is fixed on the horizontal work surface 6 below it in an inverted "L" shape, there is a space between the bottom of the buttonhole machine 3 head and the work table 6, the rear side of the buttonhole machine 3 head Arrange the head pressing assembly 4.

[0041] The pressing and feeding assembly 1 includes an upper pressing foot 9 and a lower supporting plate 8 arranged up and down, and the upper pressing foot 9 and the lower supporting plate 8 can be opened / closed; the main pressing assembly 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com