Bag clamping mechanism in automatic bagging machine

A bag machine and bag clamping technology, which is applied in the field of gravity automatic loading weighing apparatus, can solve the problems of loose structure and poor action reliability, and achieve the effect of synchronous action, flexible and reliable action, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

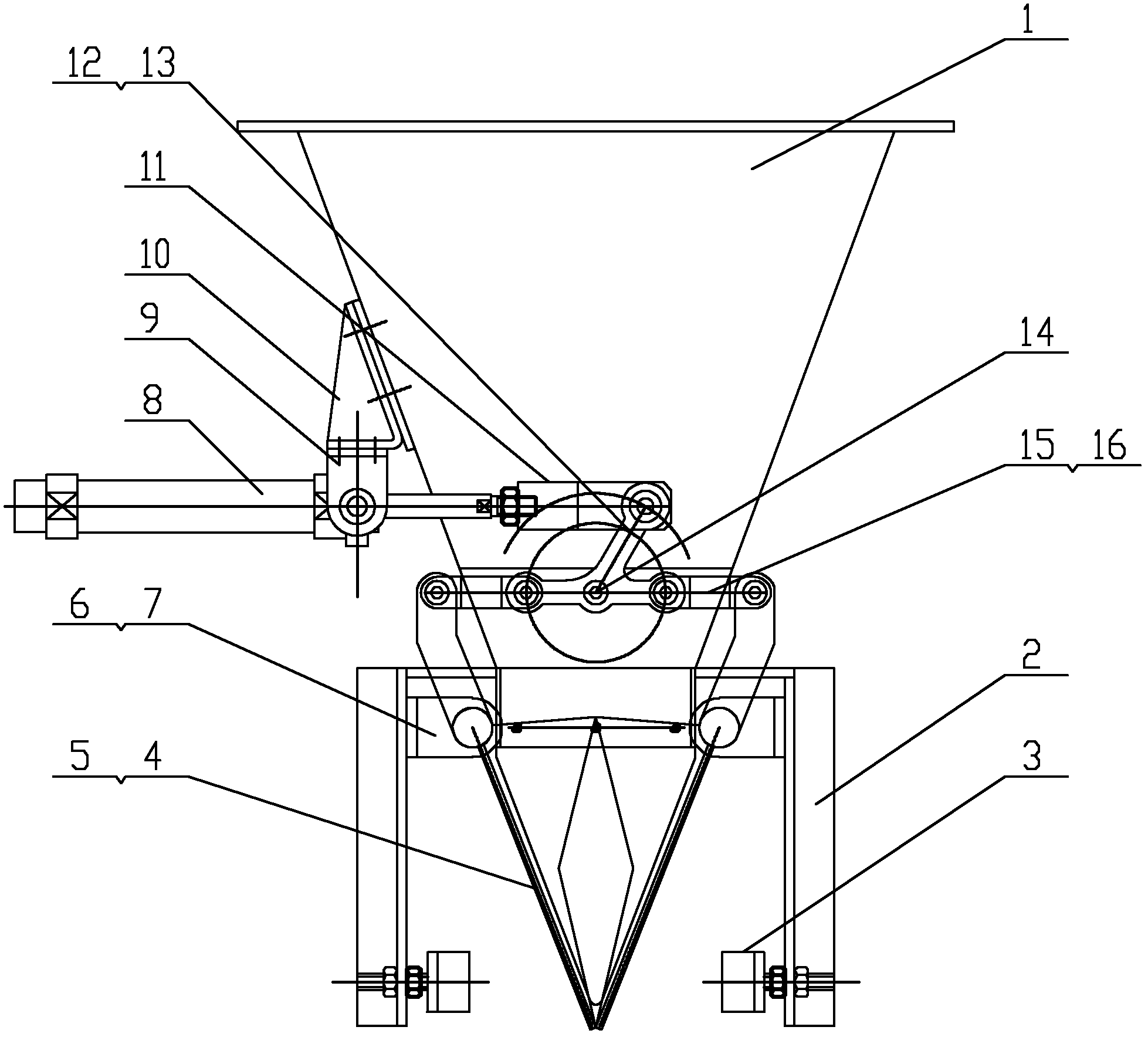

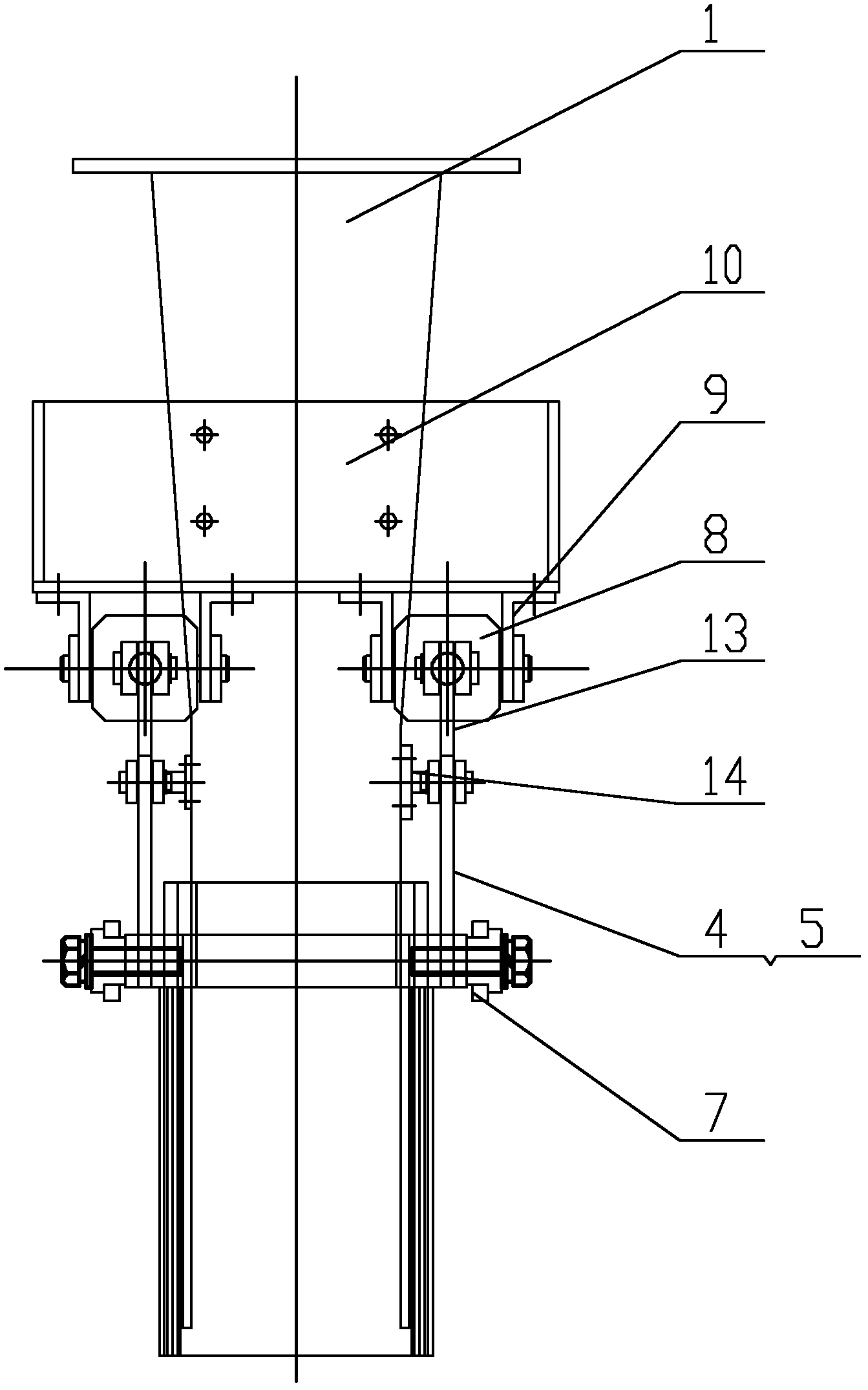

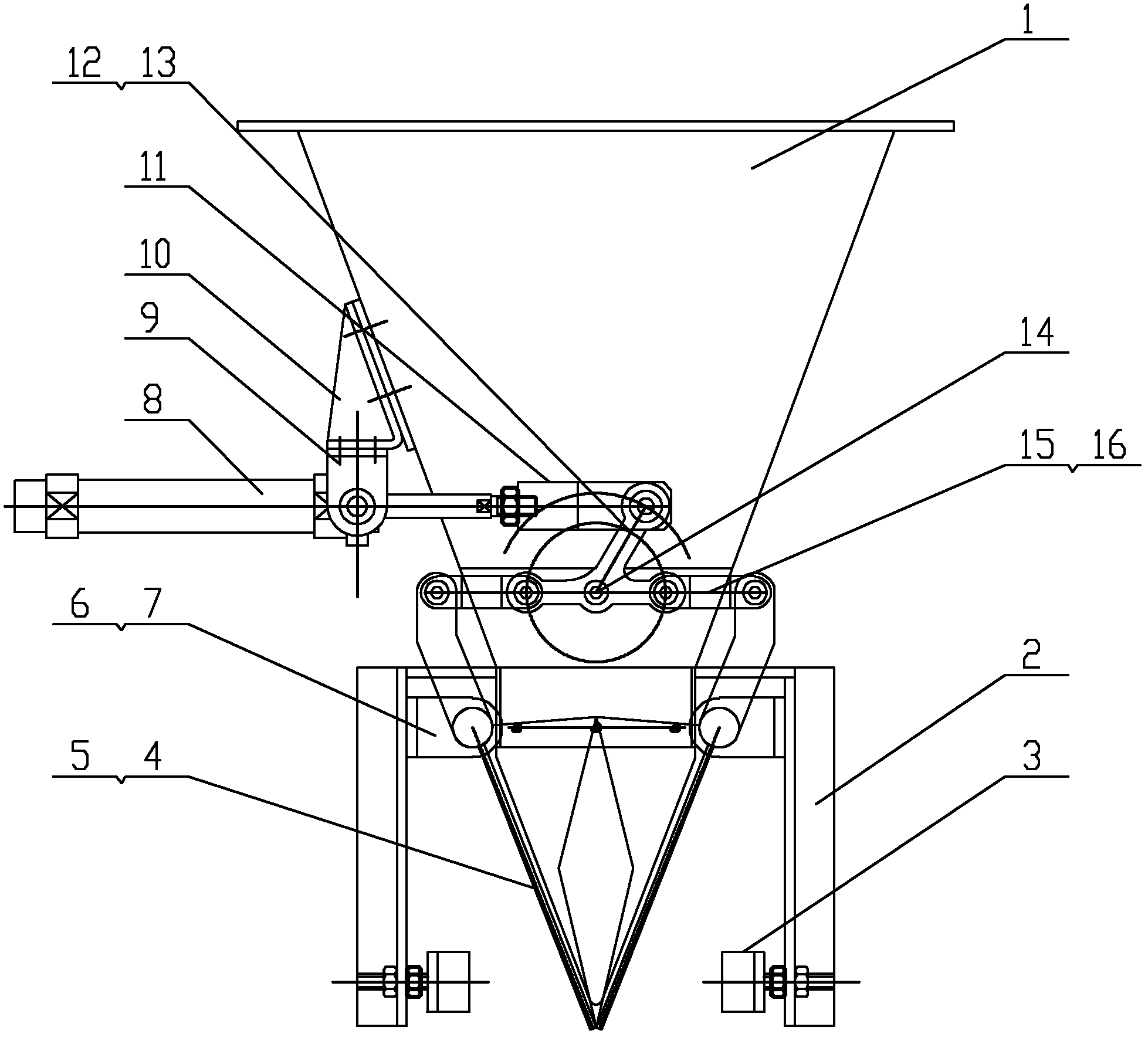

[0010] Such as Figure 1 ~ Figure 2 Shown: Including inverted cone-shaped hopper body 1, bag holder 2, tendon anti-collision block 3, left valve 4, right valve 5, valve support 6, sliding bearing 7, cylinder 8, cylinder mounting frame 9, bracket 10. Cylinder connector 11 , first pin shaft 12 , three-arm connecting rod 13 , rotating shaft 14 , connecting rod 15 and second pin shaft 16 .

[0011] The present invention is mainly made up of lower hopper, left and right valves and cylinder driving mechanism.

[0012] The lower hopper includes an inverted conical lower hopper body 1, a bag holder 2, and a beef tendon anti-collision block 3; wherein the bag holder 2 is welded to the lower end of the lower hopper body 1, and the beef tendon anti-collision block 3 is connected to the bag by bolts on the stand.

[0013] The left and right valves include a left valve 4, a right valve 5, a valve support 6, and a sliding bearing 7; wherein the valve support 6 is fixed on the bag support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com