Small size corn combine

A technology for combine harvesters and corn, which is applied to harvesters, cutters, agricultural machinery and implements, etc. It can solve the problem of long broken sections, achieve the effects of lowering the center of gravity, avoiding rollover accidents, and running smoothly and reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

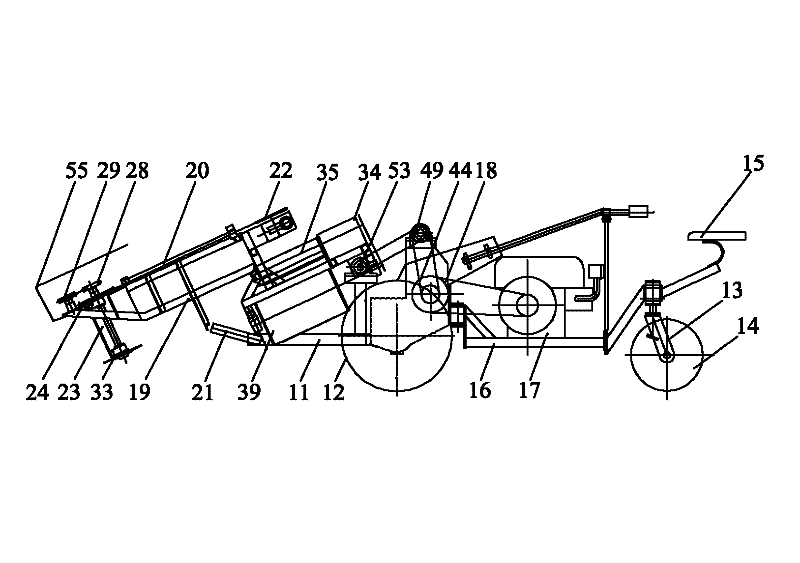

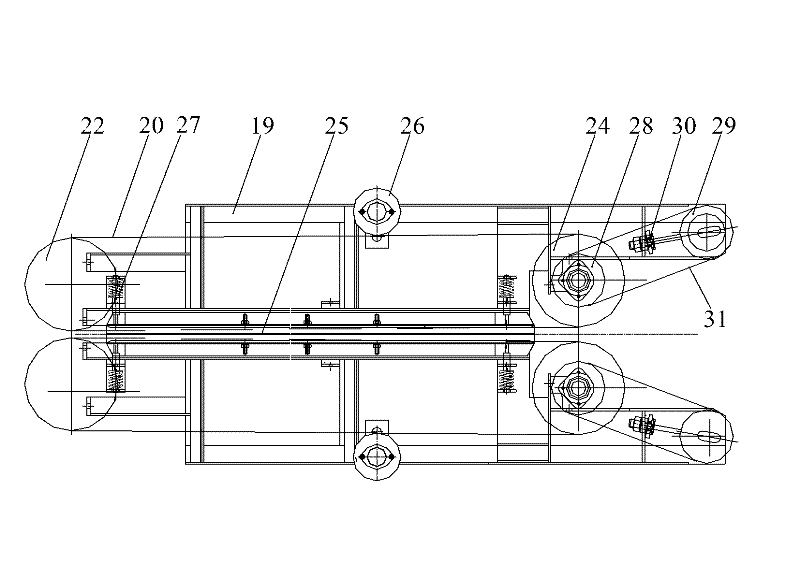

[0027] Embodiment 1 of the small-sized corn combine harvester of the present invention, as Figure 1-9 As shown, with frame 11 (as Figure 7 ), the frame 11 adopts a walking tractor frame, the frame 11 is equipped with a walking device 12 and its rear part is provided with a universal wheel 14 through a wheel frame 13, and the running device 12 is the wheel of the walking tractor itself. The steering wheel 14 can rotate 360 degrees in the vertical plane, and a driver's seat 15 is arranged on the wheel frame 13 through a support beam. Since the universal wheel 14 is arranged on the rear portion of the vehicle frame 11, it does not affect the driving process of the vehicle frame 11 during walking. The steering reduces the operating force required for steering and reduces the working intensity of the staff. In addition, the driver's seat 15 makes the operation of the operator more comfortable; An engine bracket 16 is provided and a driving device 17 is provided through the eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com