Manufacturing method and manufacturing equipment of battery metal cover plate

A technology of metal cover plate and manufacturing method, which is applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problems of low production efficiency and low product qualification rate, and achieve the improvement of production efficiency and product qualification rate, installation and riveting accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

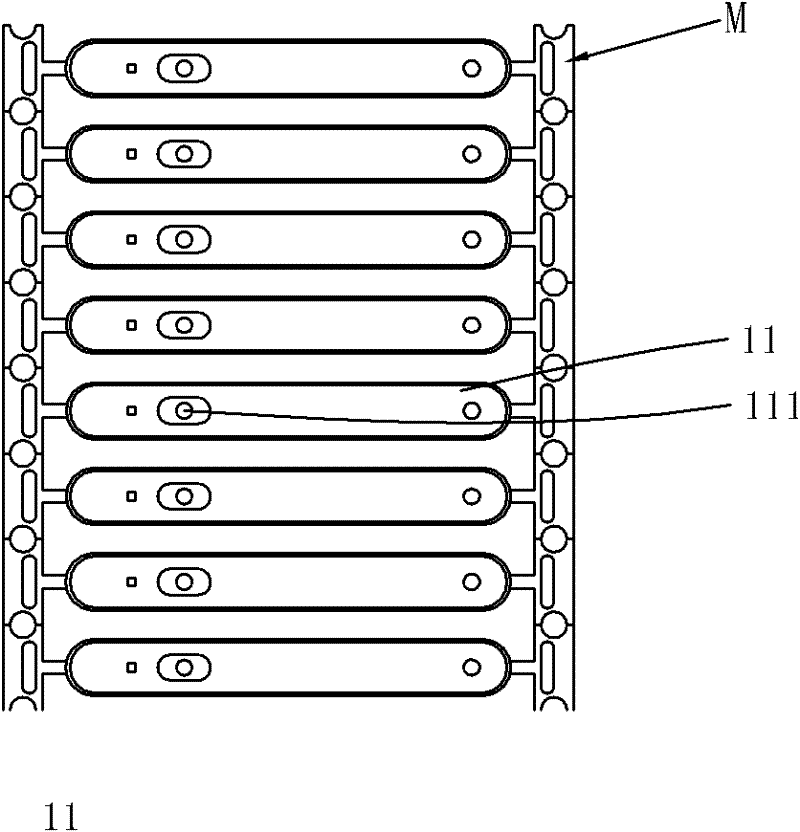

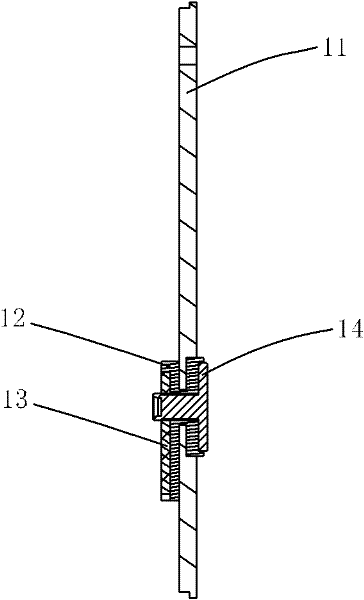

[0048] Embodiments of the present invention provide a method for manufacturing a battery metal cover plate 1 and a manufacturing device thereof.

[0049] refer to Figure 2 to Figure 4 The battery metal cover plate 1 includes a metal bracket 11, insulating glue 12, nickel sheet 13 and rivets 14, the metal bracket 11 is provided with a rivet hole 111 and an insulating glue hole 112, correspondingly, the insulating glue 12 and the nickel sheet 13 A rivet hole 121 and a rivet hole 131 are also provided on the top, and the size of the rivet hole 121 on the insulating glue 12 is slightly smaller than the diameter of the rivet 14 .

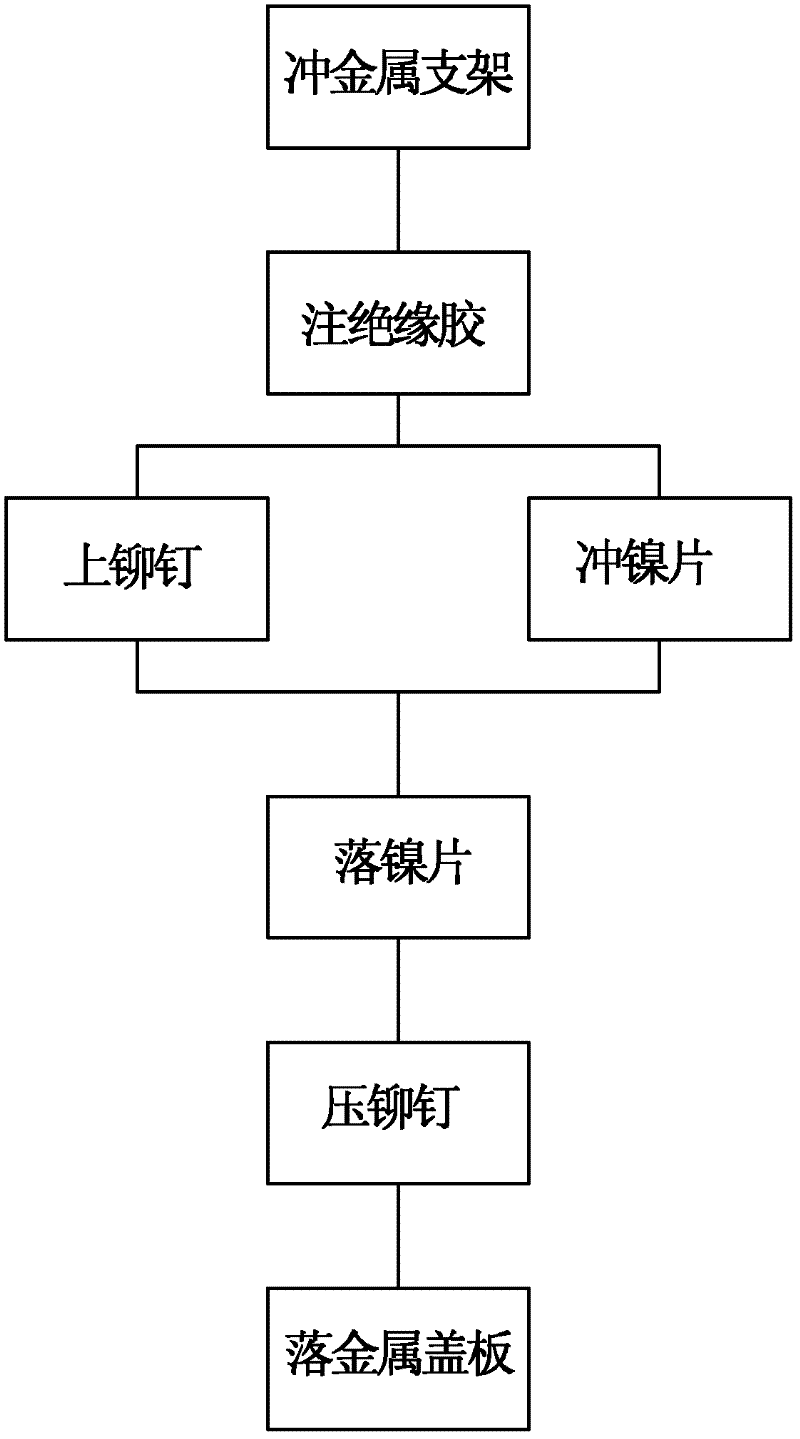

[0050] refer to Figure 5 to Figure 11 , the manufacturing method of the battery metal cover plate 1 comprises the following steps:

[0051] Punching the metal bracket step: use the first punch 3 provided with the bracket punching die 2 to punch the metal raw material belt L to obtain the primary bracket belt M with the metal bracket 11, and form the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com