Fusion fiber optic connector

An optical fiber connector and fusion splicing technology, which is applied in the field of fusion spliced optical fiber connectors, can solve the problems of limited application range and application scale, scattered connector dimensions, complicated installation process operations, etc., and achieve compact length, simplified manufacturing process requirements, The effect of simplifying on-site operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in conjunction with the accompanying drawings in the embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

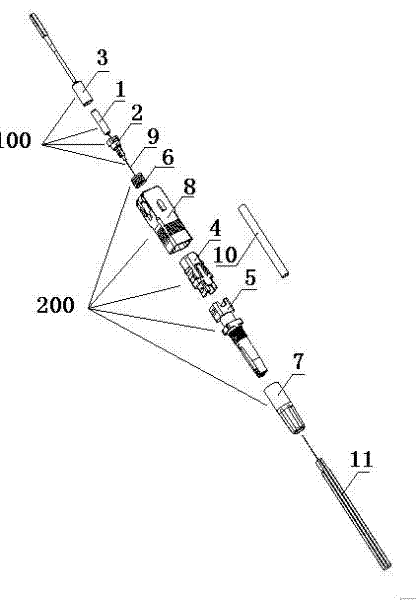

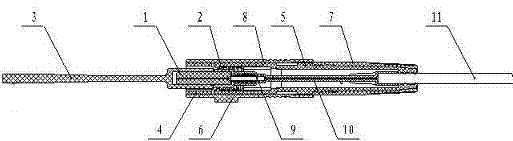

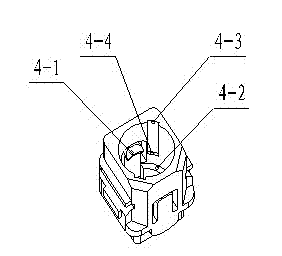

[0015] Control attached figure 1 , 2 , the fiber optic connector includes a ceramic ferrule assembly 100 and a tail assembly 200 that can be passed through on-site optical cables. The short optical fiber 9 is preset in the ceramic ferrule assembly 100, and the short optical fiber 9 passes through the tail assembly 200 that can be passed through on-site optical cables. The 11 core wires of the on-site optical cable are welded, and the fusion connection part is provided with a protective sleeve 10, and one end of the protective sleeve is connected with the ceramic pin assembly. The protective sleeve is housed in the cavity of the tail assembly and passes through the center hole of the spring. This embodiment is descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com