Anti-cracking and anti-collapse structure for newly built enclosing wall at alpine-cold region

A fence technology in alpine regions, applied to fences, buildings, building types, etc., can solve problems such as differences in water content, wall tilting, collapse, etc., and achieve the effect of simple structure and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

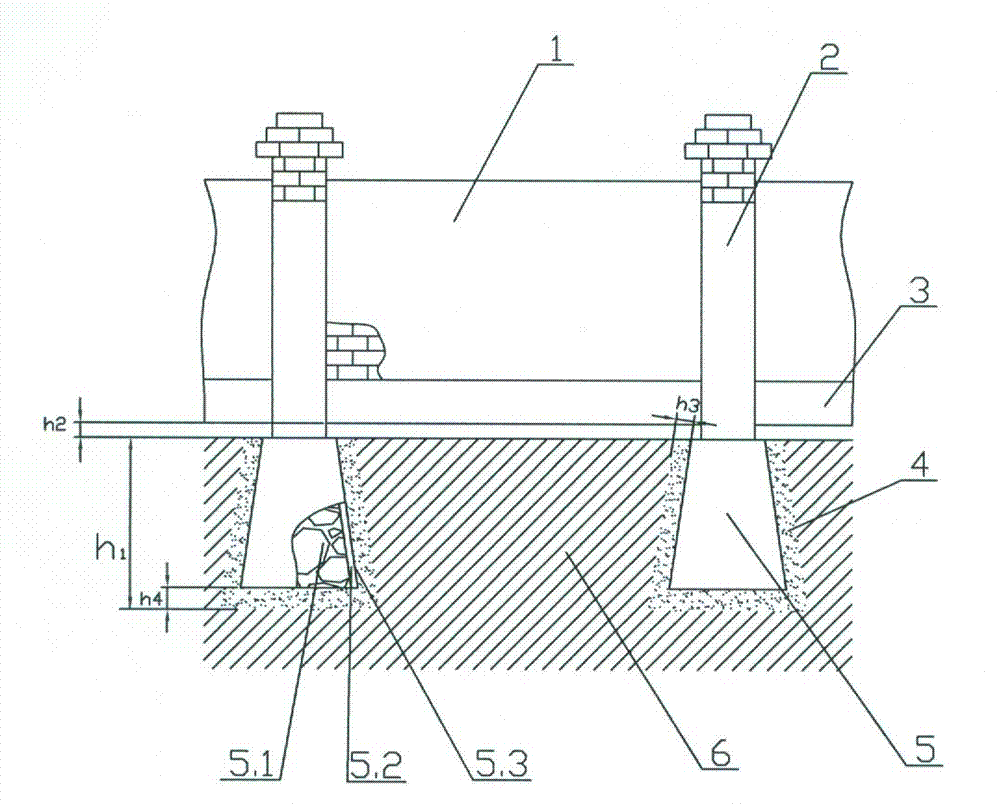

[0015] figure 1 The shown application is to build a new fence anti-crack and anti-fall structure in an alpine region, which includes a wall body 1, a wall pile 2, a bottom beam 3, a sand layer 4, a base 5 and a foundation 6. The wall 1, the wall pile 2 and the base 5 are all built-in structures, which are constructed and manufactured on site. The bottom beam 3 is a reinforced concrete prefabricated part, and its cross-sectional shape is rectangular. Base 5 is built in the foundation among the present invention, and its depth h 1 =1500mm~2000mm, the specific depth value is mainly determined according to the geological conditions of the foundation 6. If the geological conditions are good, the foundation 6 slab will take a small value, and if the geological conditions are poor, if the foundation 6 is soft or inconsistent, then a large value will be taken. poor condition, h 1 The value is 2000mm. The base 5 is in the shape of a square frustum with four sides. The main body is ...

Embodiment 2

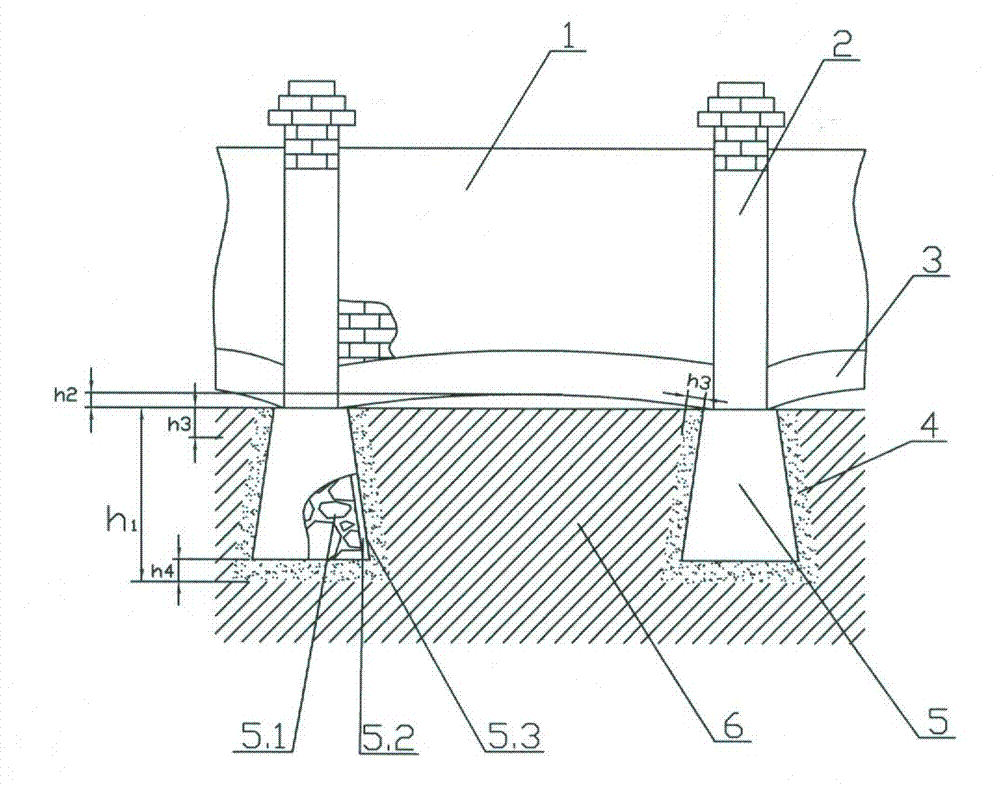

[0017] figure 2 It is a schematic structural diagram of Embodiment 2 of the present invention, figure 2 same figure 1 The structure of the shown embodiment 1 is the same, only the shape of the bottom beam 3 is different. In this embodiment, the bottom beam 3 is an upwardly convex arc beam, and its function is similar to that of a straight beam, which has better load-bearing capacity. However, the downward side of the bottom beam 3 is not parallel to the foundation 6, and the side starts from the upper surface of the foundation 6, and the distance between the middle arc top and the upper surface of the foundation 6 is the largest. In this embodiment, the bottom beam is used because of the good geological conditions of the foundation 6. The vertical distance h between the middle part of 3 and the upper surface of foundation 6 2 =100mm, base 5 is built in foundation 6, its depth h 1 =1500mm, the thickness h of the sand layer 4 between the base 5 and the side of the foundatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com