Anchored face rockfill dam and its construction method

A face rockfill dam and anchoring technology, which is applied to the construction of anchored face rockfill dams and the field of anchored face rockfill dams, can solve the problem of increased lengths of water conveyance structures and discharge structures, insufficiently compact pivot layout, and seismic stability. Insufficient and other problems to achieve the effect of reducing engineering costs, enhancing overall seismic stability, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

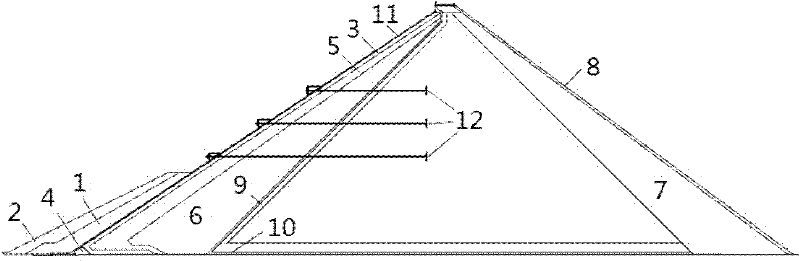

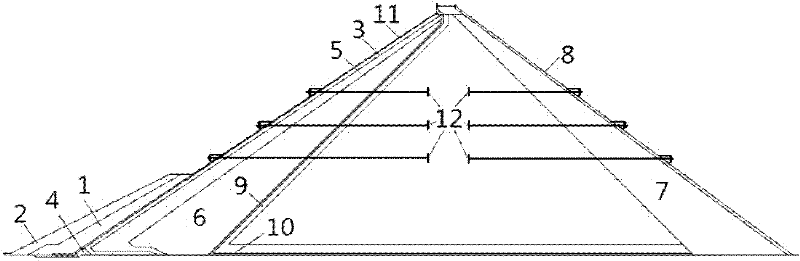

[0036] The structure of the existing face rockfill dam is divided according to the material source and the requirements of dam material strength, permeability, compressibility, convenient construction and economical rationality, and the filling standard is determined accordingly. From the upstream side of the dam body to the downstream side, a concrete face plate 11, a cushion layer area 3, a transition layer 5, a main rockfill area 6, a downstream rockfill area 7, and a downstream slope protection 8 are sequentially arranged; A special cushion area 4 is set on the side; for a dam with a high height, it is advisable to set an upstream bedding area 1 and a cover weight area 2 at the bottom of the concrete slab 11; in addition, a drainage area 9 and a reverse filter layer can also be set according to specific requirements 10.

[0037] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com