A method of producing laminated packaging material

A technology for packaging materials and production layers, applied in the field of laminated packaging materials, can solve problems such as unsatisfactory crease line effect, unavoidable barrier layer cracks, etc., to achieve good packaging forming ease, avoid stress damage, and reduce risks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

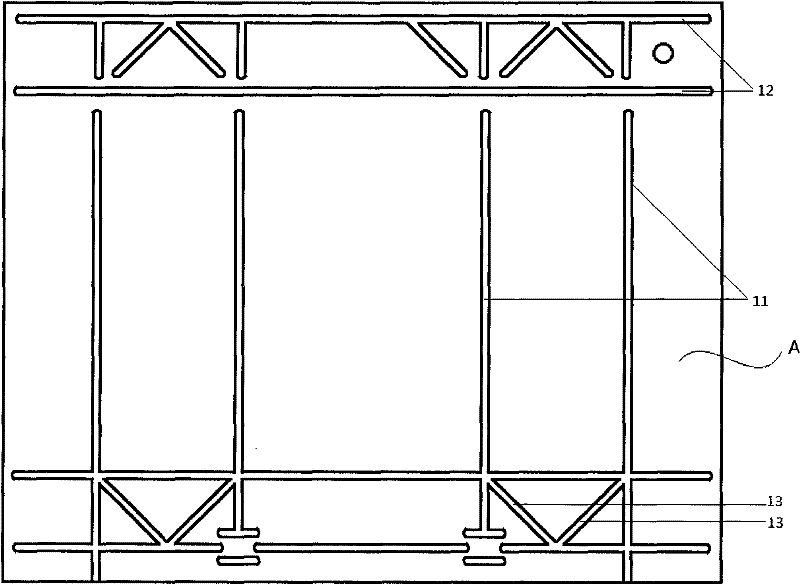

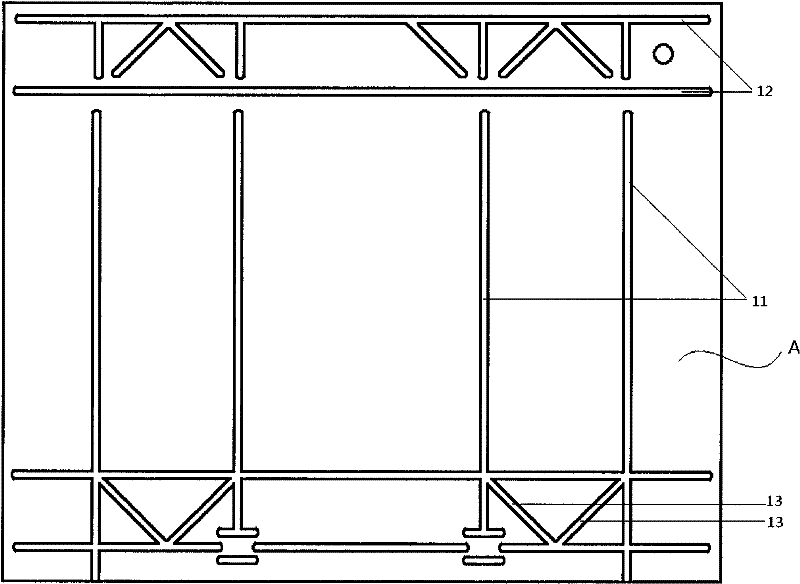

Image

Examples

Embodiment Construction

[0021] A method for producing a laminated packaging material, specifically comprising the steps of:

[0022] a. Printing a printing layer for identifying the packaging on one side of the support layer;

[0023] b. Pressing the longitudinal crease lines, transverse crease lines and oblique crease lines on the side of the above-mentioned supporting layer with the printing layer;

[0024] c. Laminating the outermost layer of thermoplastic material on the printing layer;

[0025] d. Laminating an intermediate layer of thermoplastic material, a barrier layer, an adhesive layer and an innermost layer of thermoplastic material sequentially on the side of the support layer facing away from the printing layer.

[0026] For the above step c and step d, they can be interchanged in the production process, and the beneficial technical effect of the present invention will not be affected after the interchange.

[0027] In the present invention, it is recommended to use a paper base layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com