Working elements that can be adapted to various shaft ends

A technology of working elements and shaft ends, applied in the field of working elements, can solve the problems of lack of versatility, unusable working elements, and inability to install multi-function tools, and achieves the effect of reducing manufacturing costs and simplifying process procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

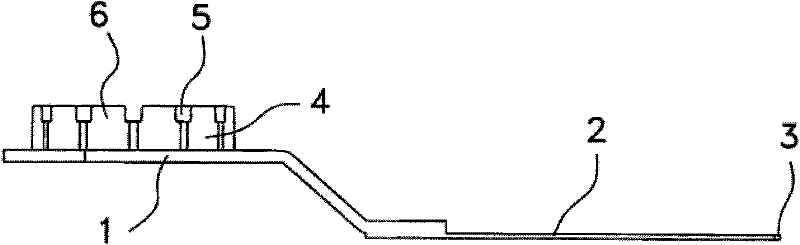

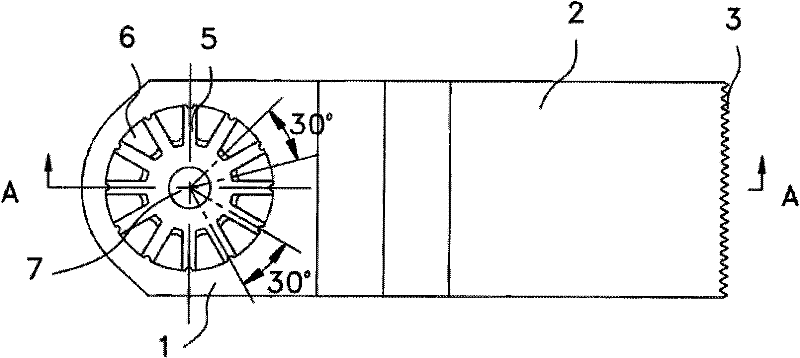

[0039] Such as Figure 1 to Figure 7 As shown, a saw blade, a working element commonly used on oscillating tools, is taken as a preferred embodiment. The saw blade includes a body part 2 and a support part 1 connected to the body part for fitting to the shaft end of a multifunctional tool. The front end of the body part 2 includes a sawtooth area 3 that can act on the workpiece to be processed to realize cutting. An adapter part 4 is provided on the support part 1 of the saw blade. The adapter part 4 and the support part 1 are integrally formed. Of course, in other implementations In the manner, the adapter part 4 may also be fixedly connected to the support part 1 by welding, riveting, screwing or other suitable connection methods. The support part 1 and the adapter part 4 form a clamping part for connecting the saw blade to the tool shaft end. The end surface of the adapter part 4 is provided with a plurality of radially penetrating grooves 5 and a plurality of protrusions ...

Embodiment approach 2

[0048] Such as Figure 8-14 Shown is the saw blade according to the second preferred embodiment of the present invention. The saw blade includes a body part 2 and a support part 1 connected to the body part. The front end of the body part 2 includes a sawtooth area suitable for acting on the workpiece to realize cutting. 3. An adapter portion 4 suitable for adapting to various shaft ends is welded on the support portion 1 of the saw blade. The support part 1 is provided with a mounting hole 7 with a longitudinal central axis Y, and a fastener such as a screw passes through the mounting hole and is connected to the shaft end when the saw blade is fixed to the shaft end. The adapter part 4 is provided with a positioning hole 310 that can limit the circumferential rotational displacement of the saw blade relative to the shaft end. The longitudinal axis of the positioning hole 310 coincides with the longitudinal central axis Y of the mounting hole 7, so that the circumferential ed...

Embodiment approach 3

[0054] Such as Figure 15 As shown, the difference between the third embodiment and the second embodiment is that the adapter part 4 in this embodiment is directly connected to the main body part 2 through the connecting handle 41 , and the support part 1 is directly connected to the adapter part 4 by welding. As for the fitting structure of the fitting part 4 , the installation structure of the supporting part 1 , and the welding connection process of the fitting part 4 and the supporting part 1 , they are all the same as those in the second embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com