Uniform-section upright main water passage alloy belt water-cooled resistor

A technology of water-cooled resistance and main waterway, applied in the direction of non-adjustable metal resistors, resistors, resistor parts, etc., can solve the problems of breeding microorganisms, many parts, complex structure, etc., to improve the ability to resist water pressure, high Strength and stability, overcoming the effect of being easily deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

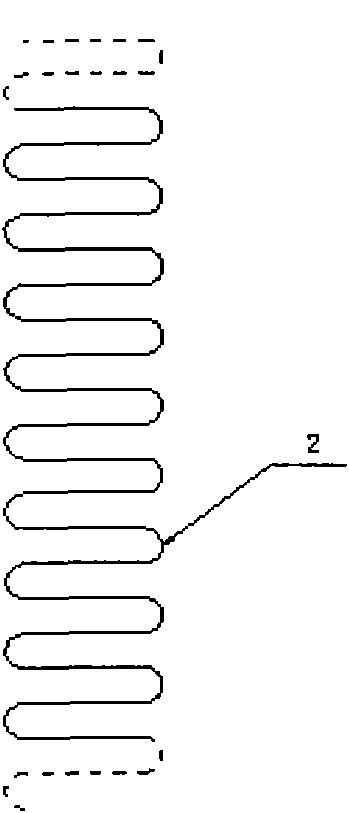

[0038] Will figure 1 The alloy strip 1 is processed into figure 2 Corrugated alloy strip2.

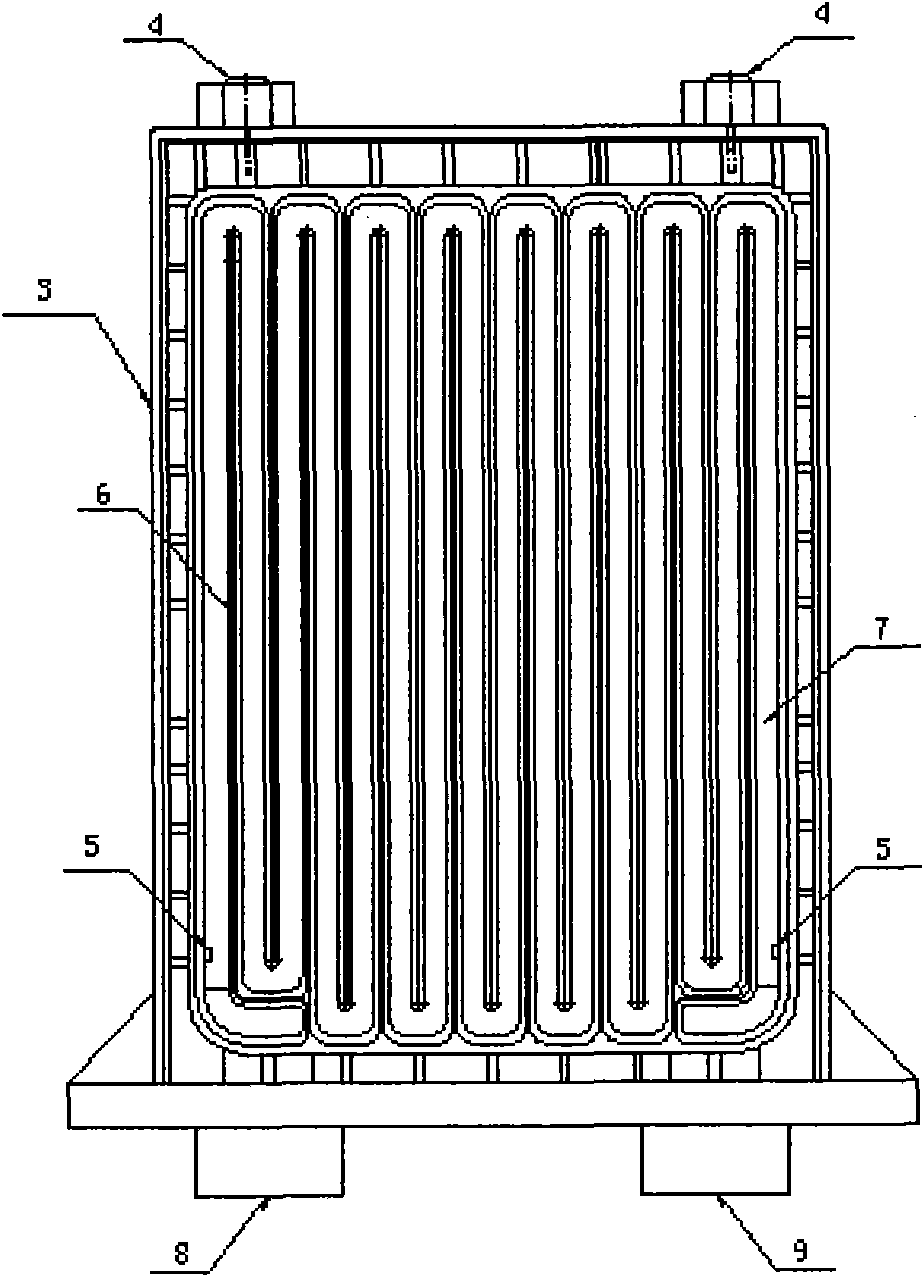

[0039] Will figure 2 Corrugated alloy strip 2 wound on image 3 In the open water tank 7 of the main waterway main board upright with equal cross-section, and the two ends of the corrugated alloy strip 2 are respectively welded on the two inner electrodes 5 to form the main board 9 with a resistance core;

[0040] Will 2 pieces Figure 5 The equal cross-section upright main waterway side plates are welded on both sides of the main board 9 with resistance cores with a hot plate machine to form the equal cross-section upright main waterway alloy strip water-cooled resistors 12 .

[0041] The above is only a preferred embodiment of the present invention, but the scope of protection of the present invention is not limited thereto. Any person skilled in the art within the technical scope disclosed in the present invention can easily think of changes or Replacement should be covered w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com