SVG device parallel operation control system and method based on optical fiber high-speed communication

An optical fiber, high-speed technology, applied in the field of SVG device parallel operation control system, can solve the problem of inability to coordinate control of multiple SVG devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

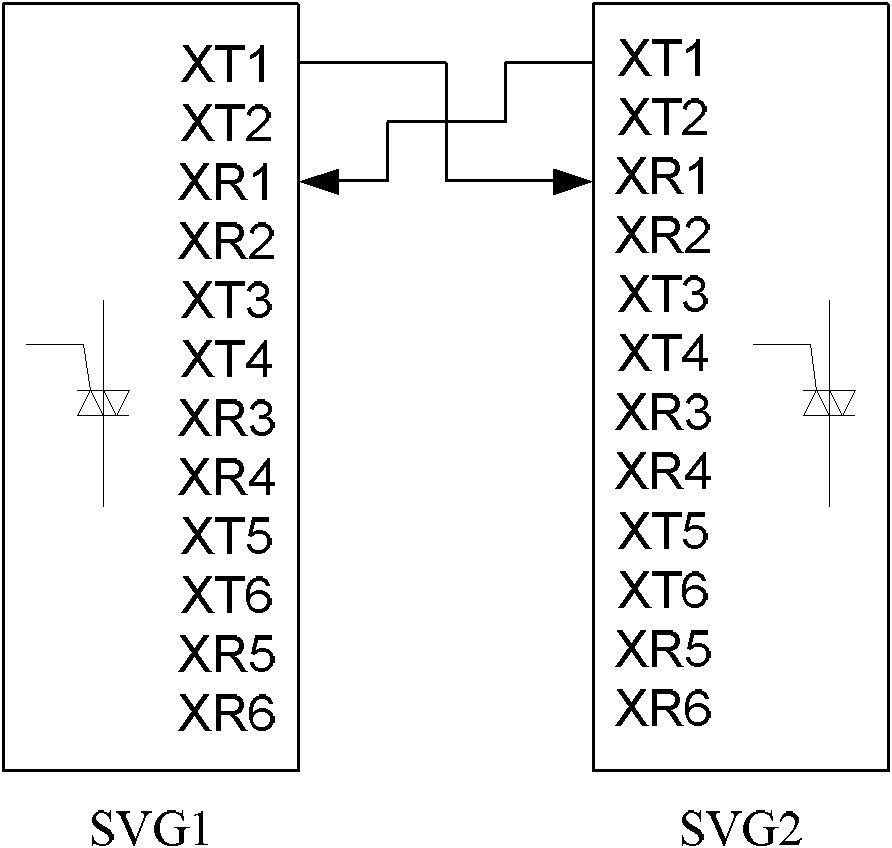

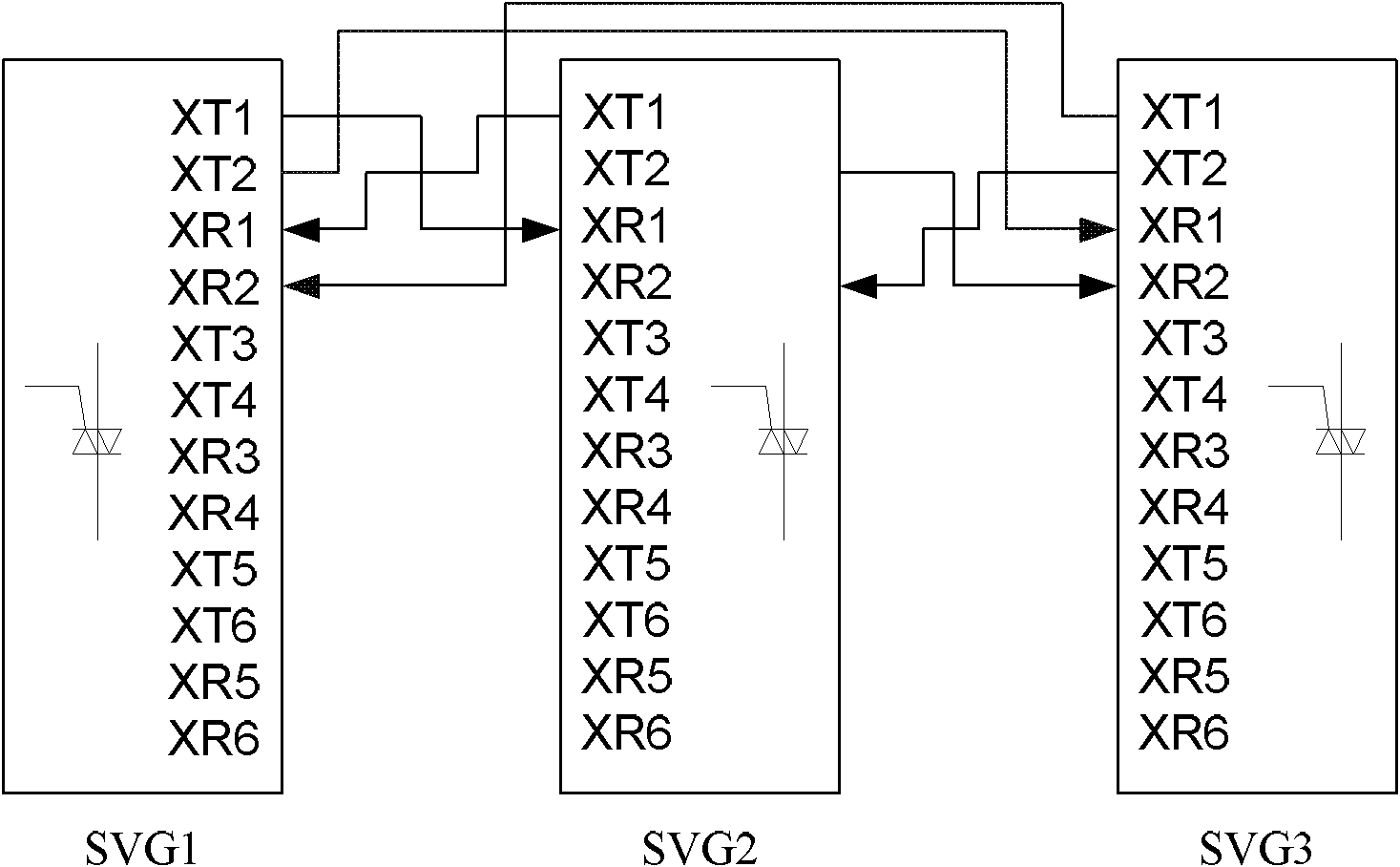

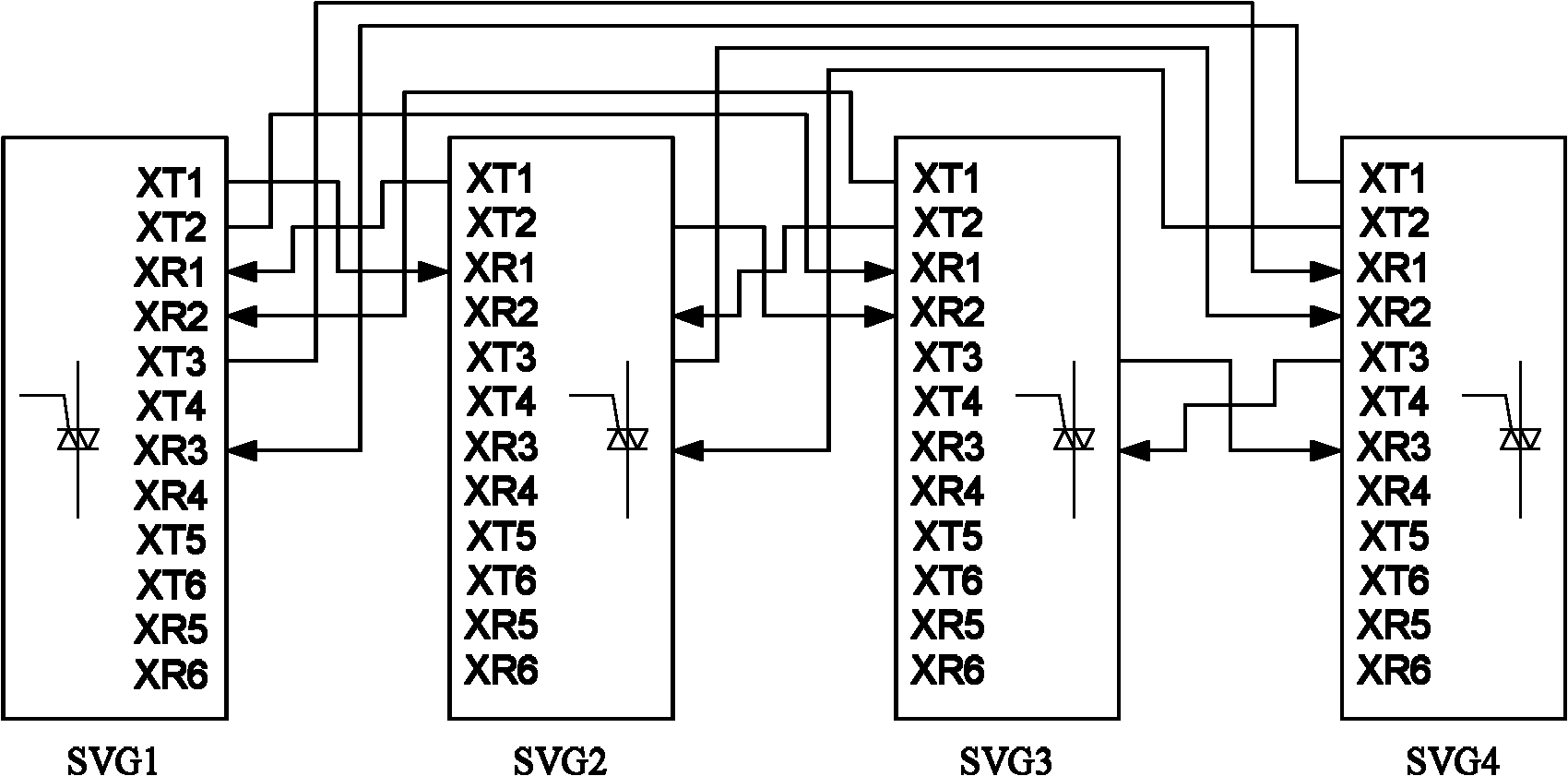

[0050] Such as figure 1 with Figure 8 As shown, this embodiment is an interconnected parallel operation control system for two SVG devices, including: two SVG devices and their corresponding communication boards, wherein: the control modules of each SVG device are connected to their corresponding communication boards through data buses and Transmission of real-time output current, reactive power and operating status information of the SVG device, the XT1 terminal of the communication board of the SVG device 1 is connected to the XR1 terminal of the communication board of the SVG device 2 through an optical fiber, and the XT1 of the SVG device 2 is connected to the XR1 of the SVG device 1 through an optical fiber , the real-time output current, reactive power and operating status information of a single SVG device is transmitted in the optical fiber.

[0051] When the SVG device adopts interconnected parallel control, it should be connected by optical fiber communication in t...

Embodiment 2

[0073] Such as Figure 7 As shown, this embodiment is a master-slave parallel operation control system for six SVG devices, including: a master controller, six SVG devices and their corresponding communication boards, wherein: the control end of the SVG device is connected to the communication board through a data bus And transmit the real-time output current and operating status information of the SVG device. The optical fiber sending and receiving ends of the six communication boards are connected to the main controller through optical fibers and transmit the real-time output current and operating status information of the SVG device.

[0074] In master-slave parallel control, if the number of SVG devices is N, the number of optical fibers required is 2N.

[0075] The main controller includes: a voltage and current conditioning circuit, a programmable chip and a sampling circuit, a digital signal processing chip, six groups of optical fiber receiving terminals and six groups...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com