Lithium lanthanum zirconium oxide solid electrolyte material and its preparation method and application

A solid electrolyte, lithium lanthanum zirconium oxide technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as waste of lithium raw materials, achieve the effects of saving consumption, reducing production costs, and high room temperature ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

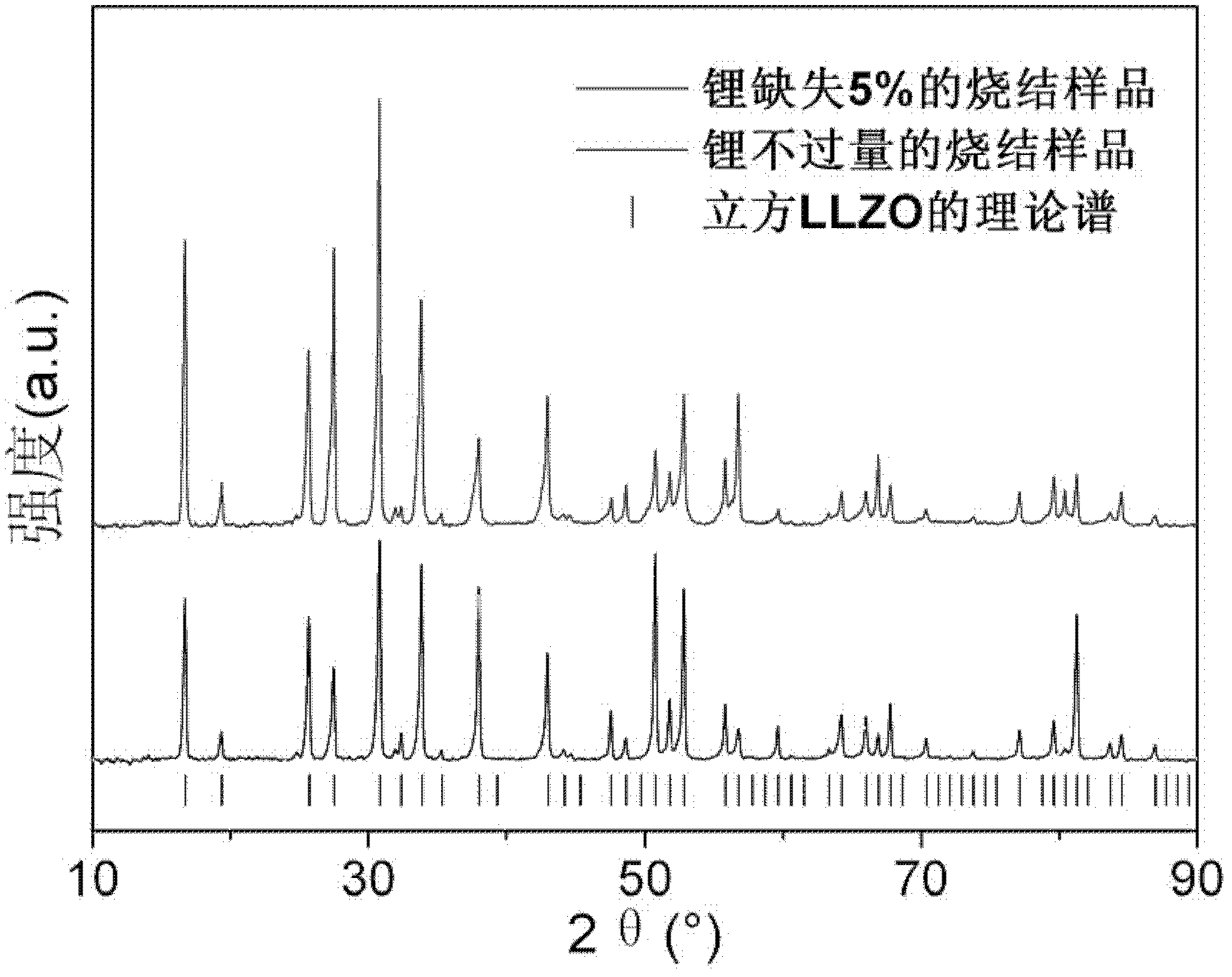

[0023] Embodiment 1, preparation Li 7+x La 3 Zr 2 o 12+0.5x (x=-0.35) lithium lanthanum zirconium oxygen solid electrolyte material

[0024] 6.976 grams of the lithium source compound lithium hydroxide, 12.217 grams of the lanthanum source compound lanthanum oxide, and 6.161 grams of the zirconium source compound zirconia were ball-milled and mixed in an isopropanol medium according to the molar ratio of Li, La and Zr of 6.65:3:2 for 18 hours, then dried at 75°C, calcined at 800°C for 15 hours, ball milled in isopropanol medium for 24 hours, dried at 80°C, pre-pressed at 4MPa, and then cooled at 200MPa After isostatic pressing for 5 minutes, the green body after molding was sintered at 1200 ° C for 35 hours to obtain the Li 7+x La 3Zr 2 o 12+0.5x (x=-0.35) lithium lanthanum zirconium oxygen solid electrolyte material.

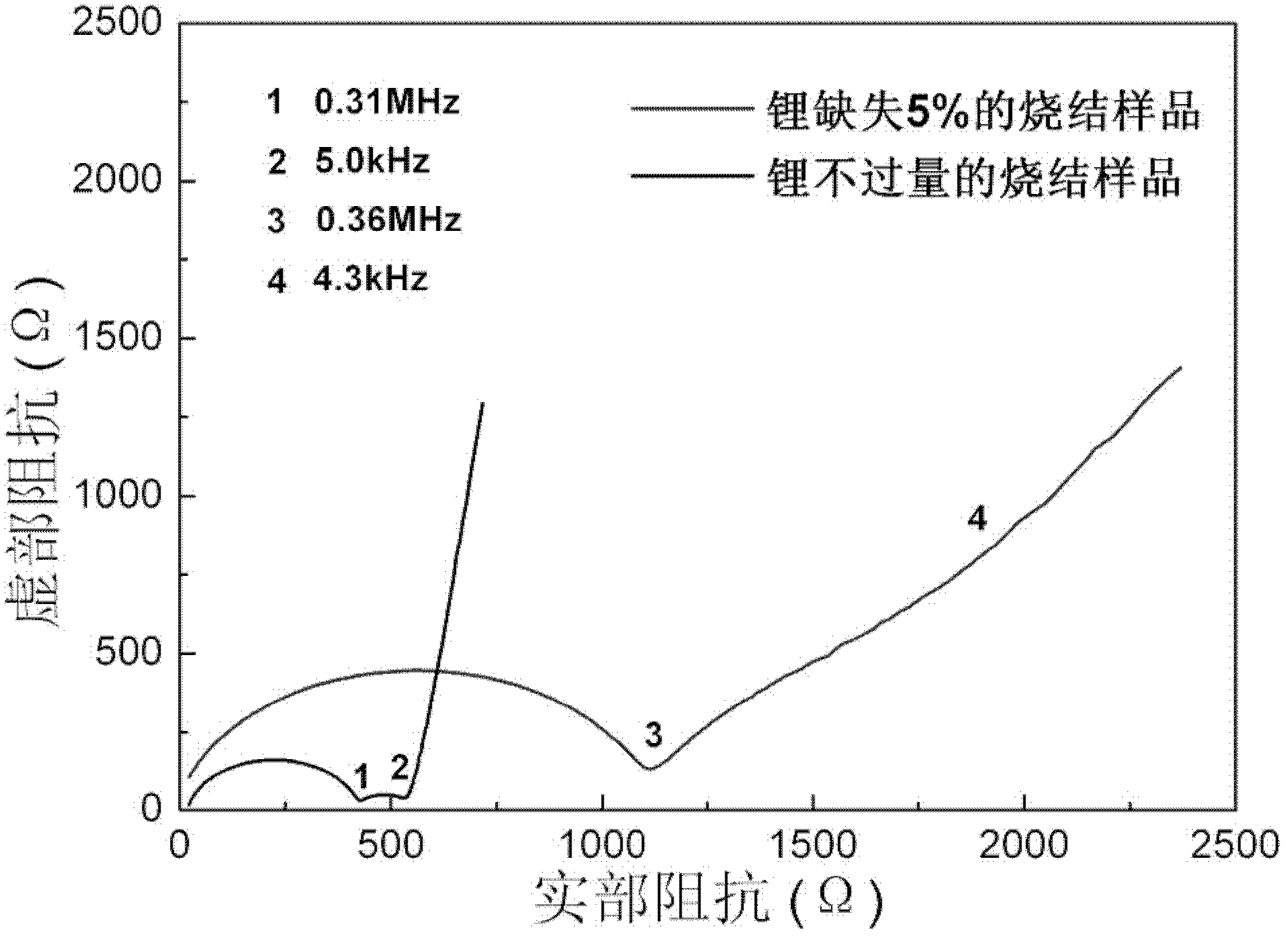

[0025] The lithium lanthanum zirconium oxygen solid electrolyte material has a total resistance of 27574 ohms, a thickness of 1.71 mm, a diameter of 11...

Embodiment 2

[0026] Embodiment 2, preparation Li 7+x La 3 Zr 2 o 12+0.5x (x=0) Lithium Lanthanum Zirconium Oxygen Solid Electrolyte Material

[0027] 7.343 grams of the lithium source compound lithium hydroxide, 12.217 grams of the lanthanum source compound lanthanum oxide and 6.161 grams of the zirconium source compound zirconia were ball milled and mixed in an isopropanol medium according to the molar ratio of Li, La and Zr of 7:3:2 for 18 hours, then dried at 75°C, calcined at 800°C for 15 hours, ball milled in isopropanol medium for 24 hours, dried at 80°C, pre-pressed at 4MPa, and then cooled at 200MPa After isostatic pressing for 5 minutes, the green body after molding was sintered at 1200 ° C for 35 hours to obtain the Li 7+x La 3 Zr 2 o 12+0.5x (x=0) lithium lanthanum zirconium oxygen solid electrolyte material.

[0028] The lithium lanthanum zirconium oxygen solid electrolyte material has a total resistance of 523 ohms, a thickness of 0.93 mm, a diameter of 10.85 mm, and a...

Embodiment 3

[0031] Embodiment 3, preparation Li 7+x La 3 Zr 2 o 12+0.5x (x=0.35) lithium lanthanum zirconium oxygen solid electrolyte material

[0032] 7.710 grams of the lithium source compound lithium hydroxide, 12.217 grams of the lanthanum source compound lanthanum oxide, and 6.161 grams of the zirconium source compound zirconia were ball milled and mixed in an isopropanol medium according to the molar ratio of Li, La and Zr of 7.35:3:2 for 18 hours, then dried at 75°C, calcined at 800°C for 15 hours, ball milled in isopropanol medium for 24 hours, dried at 80°C, pre-pressed at 4MPa, and then cooled at 200MPa After isostatic pressing for 5 minutes, the green body after molding was sintered at 1200 ° C for 35 hours to obtain the Li 7+x La 3 Zr 2 o 12+0.5x (x=0) lithium lanthanum zirconium oxygen solid electrolyte material.

[0033] The lithium lanthanum zirconium oxygen solid electrolyte material has a total resistance of 911 ohms, a thickness of 1.23 mm, a diameter of 11.17 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com