A Method for Measuring and Converting Domain Reversal Current of Insulated/Leakage Ferroelectric Thin Film into Hysteresis Loop

A ferroelectric thin film, reverse current technology, applied in the direction of measuring electrical variables, measuring current/voltage, measuring devices, etc., can solve the problem of lack of test functions, and achieve the effect of increasing the difficulty of distinguishing and fast measuring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and examples, and the given examples are only used to explain the present invention, not to limit the present invention.

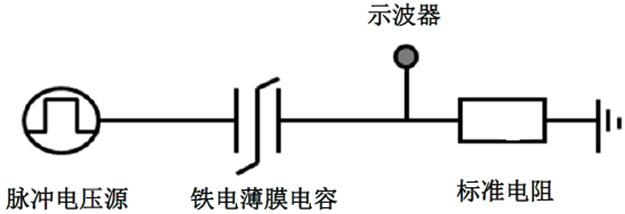

[0028] The pulse signals required for the test are provided by Agilent 81150A arbitrary waveform signal generator through R t The voltage (or current) across both terminals is recorded by LCWR 6200A oscilloscope, R t = 100 ohms.

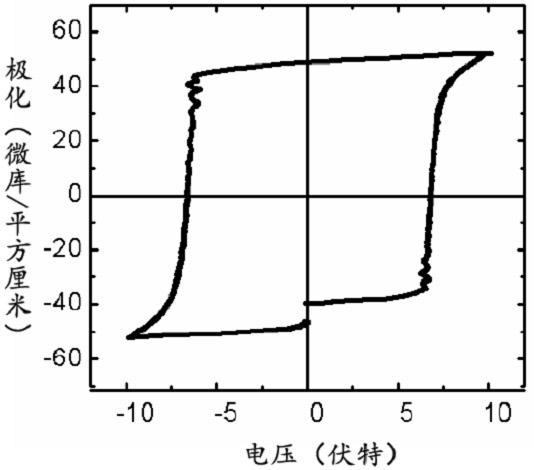

[0029] One, measure insulating bismuth ferrite film capacitor (BiFeO2) by the present invention 3 / SrRuO 3 / SrTiO 3 ) hysteresis loop, BiFeO 3 The thickness is 300nm, the electrode area S=3.14×10 -3 cm 2 .

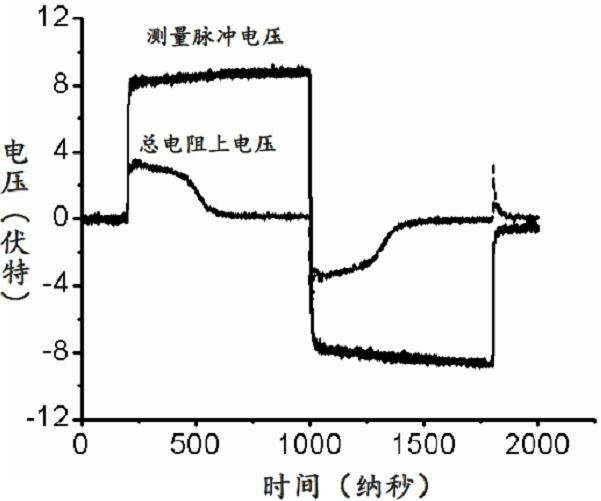

[0030] (1) Connect the ferroelectric film to be tested in series with the signal generator, oscilloscope, standard resistance, etc., and use the pulse signal generator to generate a bipolar voltage pulse (pulse width 750 nanoseconds, amplitude 8V, such as figure 2 shown), the voltage V across the total resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com