Constant-force self-locking differential screw fine-tuning device

A technology of fine-tuning device and differential screw, which is applied in the direction of shafts, bearings, connecting rods, mechanical equipment, etc., can solve the problems affecting the movement accuracy of components or parts, and it is difficult to parallel the centerlines of the holes at both ends of the connecting rod and the hole distance. To achieve the effect of simple structure, improve equality and periodic motion position, and reduce motion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

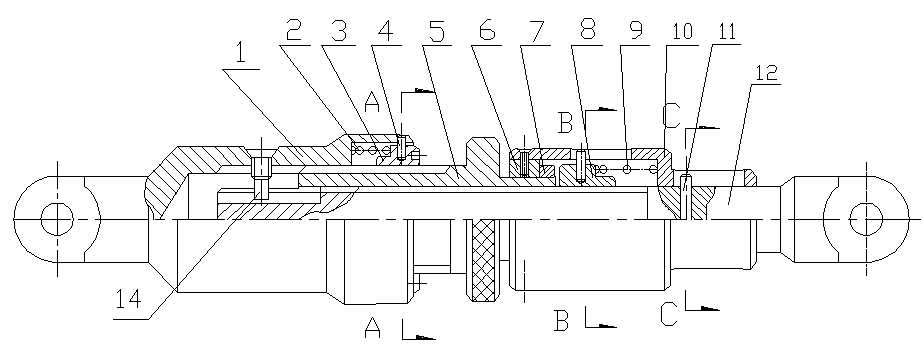

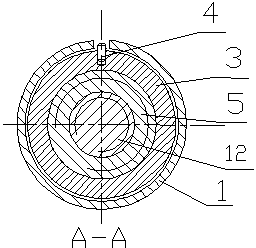

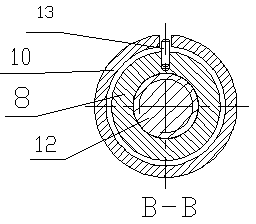

[0011] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] Such as Figure 1-4 As shown, the fine-tuning device includes an adjustment body, a main connecting rod body and an auxiliary connecting rod body. The internal thread of the main connecting rod body and the external thread of the auxiliary connecting rod body are respectively connected with the external thread and the internal thread of the adjusting body to form a differential The fine-tuning device; the regulating body includes an adjusting screw sleeve 5, an inner sleeve 6 and an outer sleeve 7, and the inner sleeve 6 and the outer sleeve 7 are sequentially inserted on the outer cylinder at the right end of the adjusting screw sleeve 5, and through the outer sleeve 7 and the adjusting screw sleeve 5 The riveted connection of the right end surface enables the inner sleeve 6 to freely rotate on the adjusting screw sleeve 5 and achieve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com