Universal fuel gas mixing valve suitable for gas supply by different gas sources

A mixing valve and gas source technology, which is applied in the direction of oil supply devices, combustion engines, internal combustion piston engines, etc., can solve the problems of gas source leakage, engine power performance and emissions cannot be effectively controlled, and inconvenient use, etc., to achieve safety assurance , solve the effect of stable performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

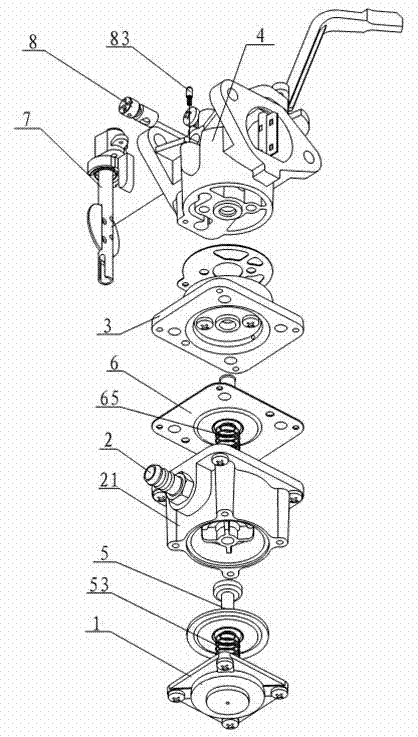

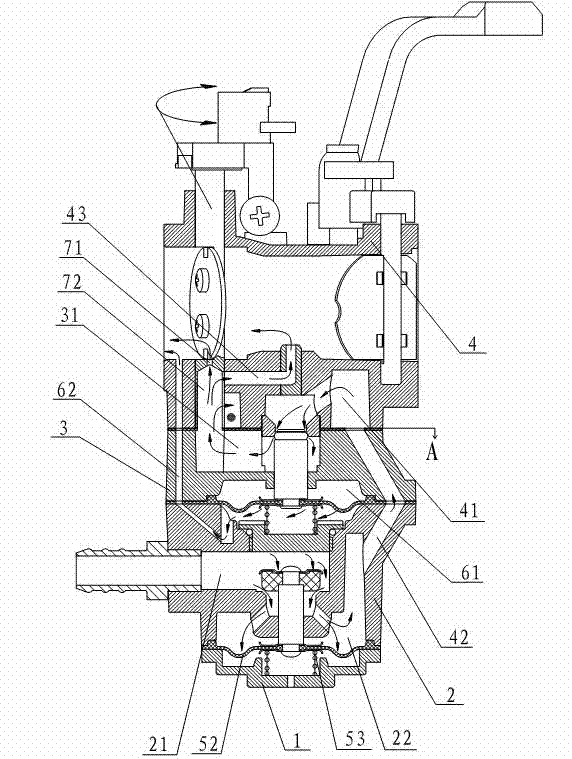

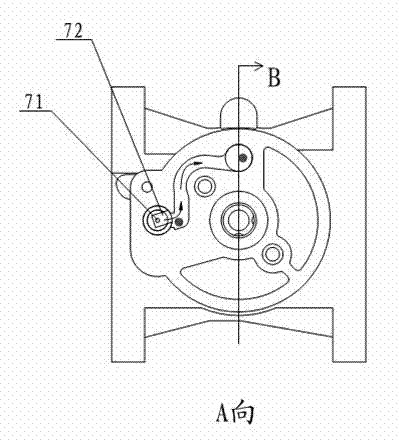

[0041] Please refer to the attached Figure 1 to Figure 6-4 As shown, the present invention is a general-purpose gas mixing valve, and its applicable gas sources include petroleum liquefied gas, natural gas, biogas and other gas sources, and it is mainly composed of sequentially connecting the cover plate 1, the valve lower body 2, the valve middle body 3, and the valve upper body. Body 4, double-cascade decompression device 5, switch diaphragm assembly 6, throttle assembly 7, multi-fuel conversion shaft 8 and other components. Wherein, the cover plate 1 , the lower valve body 2 , the valve middle body 3 and the valve upper body 4 are sequentially connected from bottom to top to form a casing.

[0042] One end of the lower valve body 2 is provided with an air source inlet 21 . A first accommodation cavity 22 is formed between the cover plate 1 and the lower valve body 2 . The double-cascade simultaneous decompression device 5 is located in the first storage chamber 22 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com