An antibacterial and anti-asthma finishing solution and its preparation and application on fabrics

A technology of finishing liquid and anti-mite finishing agent, which is applied in the fields of fiber treatment, textiles and papermaking, etc. It can solve the problem of anti-mite, which is a big headache, and achieve the effect of preventing mite-related diseases. The method is simple and easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

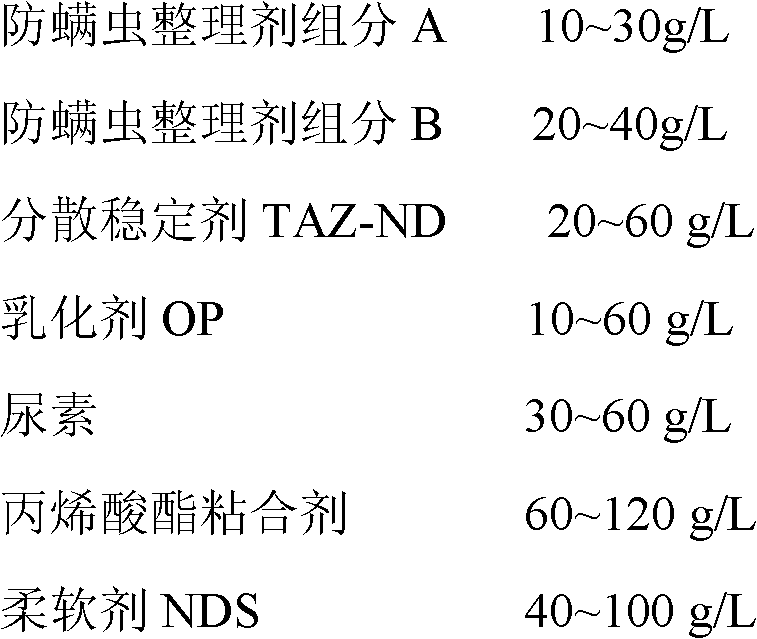

[0039] An antibacterial and anti-asthma finishing solution, the formula of the finishing solution comprises:

[0040] ZnO 2 20g / L, dispersion stabilizer TAZ-ND 20g / L, N,N-diethyl-3-methylbenzamide 30g / L, emulsifier OP 20g / L, urea 30g / L, acrylate adhesive 80g / L, softener NDS 40g / L, solvent is water.

[0041] It is prepared as follows:

[0042] Add most of the water first, then add the ZnO with rapid stirring 2 20g / L, dispersion stabilizer TAZ-ND 20g / L, then add N,N-diethyl-3-methylbenzamide 30g / L, emulsifier OP 20g / L, then add urea 30g / L, acrylic acid Ester binder 80g / L, softener NDS40g / L, continue to stir. The prepared bath should be used as soon as possible.

[0043] Its application is as follows:

[0044] Process flow:

[0045] The quilt cover fabric that has been pre-treated, dyed or printed is padded with the above finishing solution (the liquid rate is 70%), dried (100°C), and tented (130~140°C×30s)

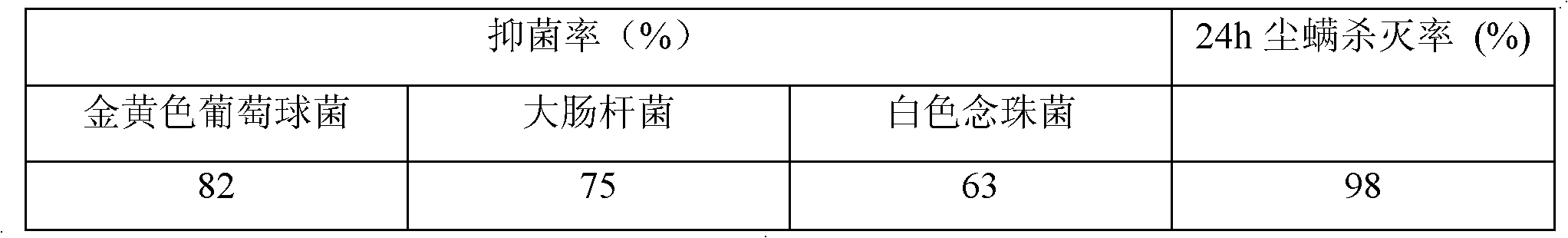

[0046] Performance test of quilt cover fabric:

[0047]

Embodiment 2

[0049] An antibacterial and anti-asthma finishing solution, the formula of the finishing solution comprises:

[0050] TiO 2 20g / L, dispersion stabilizer TAZ-ND 25g / L, 3-phenoxybenzyl-2,2-dimethyl-3-(2,2-dichlorovinyl)-cyclopropanecarboxylate 20g / L, emulsifier OP 20g / L, urea 30g / L, acrylate adhesive 60g / L, softener NDS60g / L, solvent is water.

[0051] It is prepared as follows:

[0052] Add most of the water first, then add the TiO with rapid stirring 2 20g / L, dispersion stabilizer TAZ-ND 25g / L, then add 3-phenoxybenzyl-2,2-dimethyl-3-(2,2-dichlorovinyl)-cyclopropanecarboxylate 20g / L, emulsifier OP 20g / L, then add urea 30g / L, acrylate adhesive 60g / L, softener NDS60g / L, and continue stirring. The prepared bath should be used as soon as possible.

[0053] Its application is as follows:

[0054] After pretreatment, the dyed or printed quilt cover fabric is padded with the above finishing solution (the liquid rate is 65%), dried (80°C), and stretched (120°C×2min)

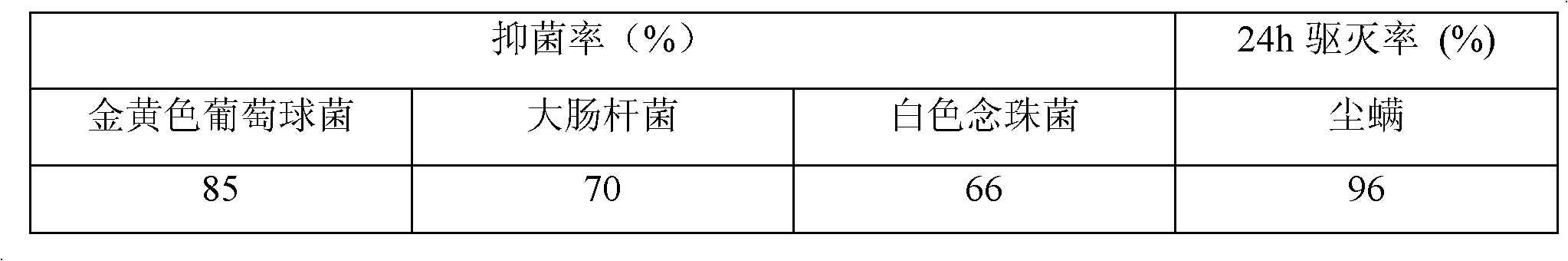

[0055]...

Embodiment 3

[0058] An antibacterial and anti-asthma finishing solution, the formula of the finishing solution comprises:

[0059] ZnO 10g / L, ZrO 10g / L, dispersion stabilizer TAZ-ND 35g / L, a-cyano-3-phenoxybenzyl-2,2-dimethyl-3-(2,2-dichloro Vinyl)-cyclopropane carboxylate 20g / L, emulsifier OP 30g / L, urea 30g / L, acrylate adhesive 60g / L, softener NDS 60g / L, solvent is water.

[0060] It is prepared as follows:

[0061] Add most of the water first, add ZnO 10g / L, ZrO 10g / L, dispersion stabilizer TAZ-ND 35g / L under rapid stirring, then add a-cyano-3-phenoxybenzyl-2,2- Dimethyl-3-(2,2-dichlorovinyl)-cyclopropanecarboxylate 20g / L, emulsifier OP 30g / L, then add urea 30g / L, acrylate adhesive 60g / L, soft Agent NDS60g / L, continue to stir. The prepared bath should be used as soon as possible.

[0062] Its application is as follows:

[0063] After pretreatment, the dyed or printed quilt cover fabric is padded with the above finishing solution (the liquid rate is 70%), dried (100°C), and tented (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com