Fiber bundle finishing and aligning equipment with adjustable beating amplitude and frequency

A fiber bundle and equipment technology, which is applied in the field of fiber bundle sorting and alignment equipment, can solve the problems of high labor intensity and low efficiency, and achieve the effects of increased productivity, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

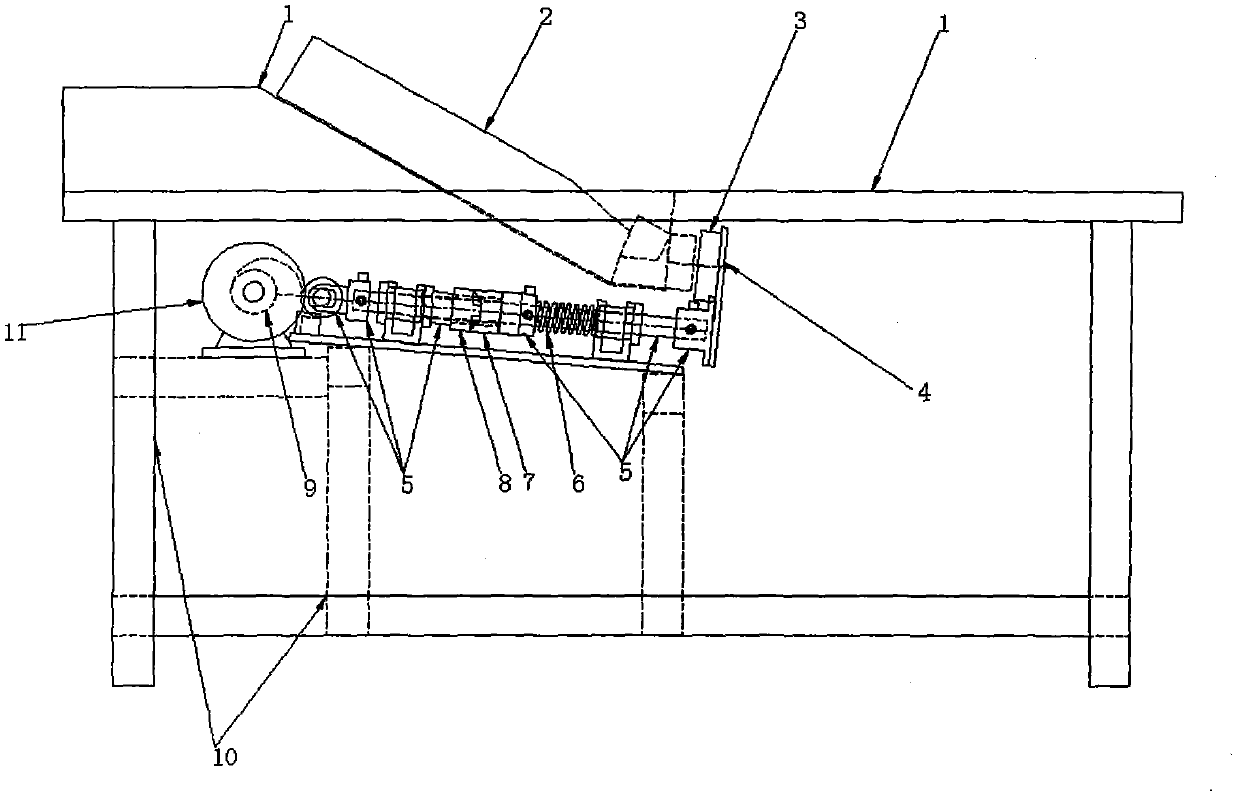

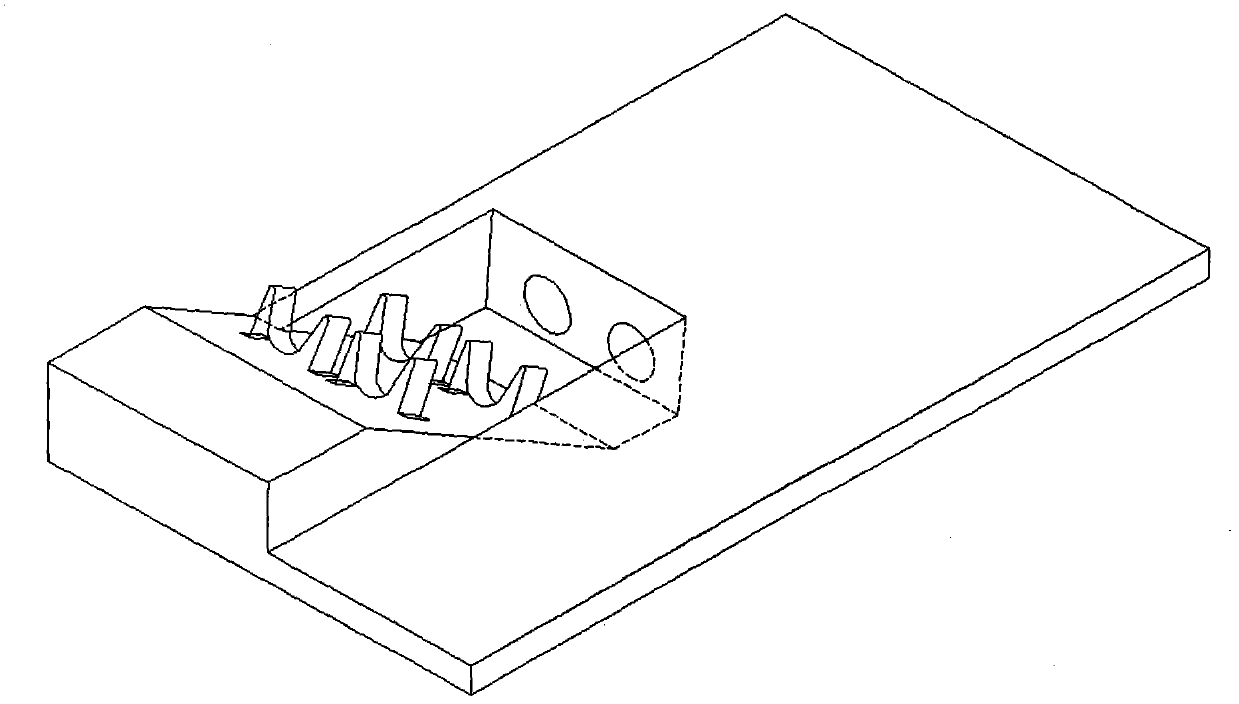

[0036] Embodiment 1: as Figure 1-6 Shown, a kind of beating amplitude and the adjustable fiber bundle finishing and beating equipment of frequency, be provided with frame (10), working table (1), fiber supply container (2), clapper device (3) in described equipment , 4), transmission device (5, 6, 9, 11) and adjustment device (7, 8), transmission device contains power source (11), cam (9), linear motion component (5), spring (6), One end of the spring is fixed on the linear moving part, and the other end is stationary and fixed. The power source drives the cam to rotate, and the cam rotation drives the linear moving part to do work on the spring. The spring does work to the linear moving part. On the bundle tidying surface, the fiber supply container is placed on the card slot of the worktable, and the fiber bundle is supplied to the clapper device of the fiber finisher by means of the fiber supply container, and the clapper device is perpendicular to the direction of the fib...

Embodiment 2

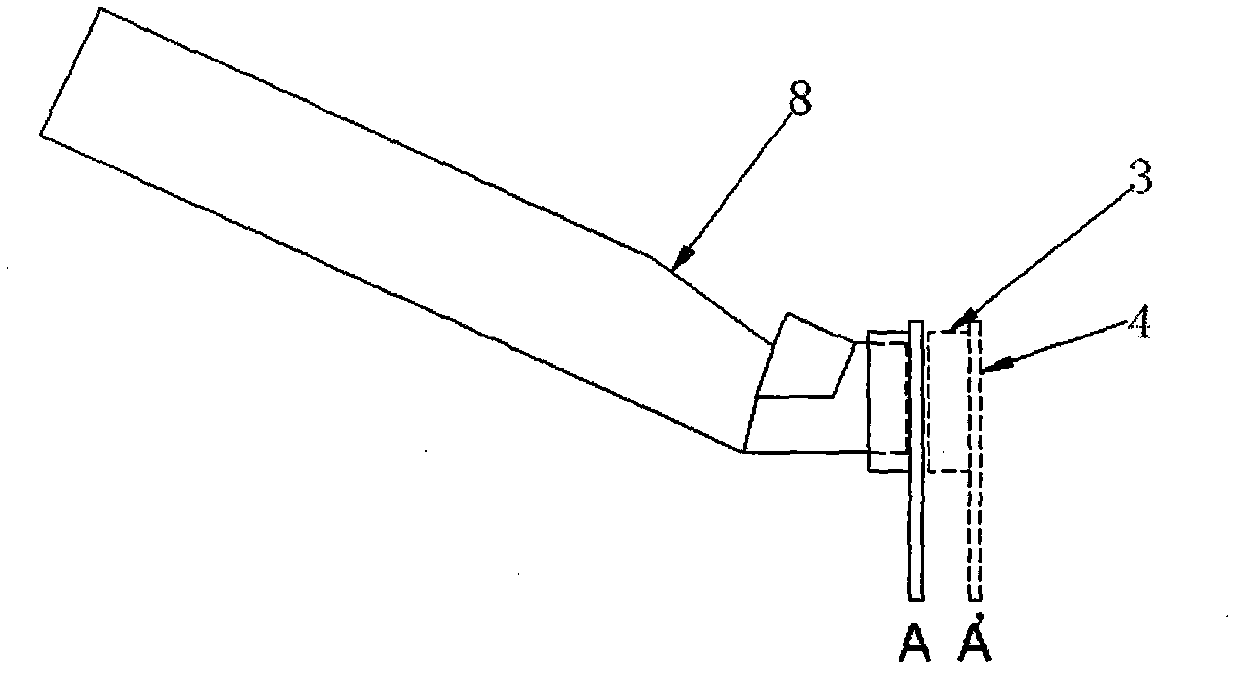

[0046] Embodiment 2: as figure 1 and 2As shown, the clapper device and the linear moving parts move synchronously, and the moving direction is perpendicular to the neat surface of the fiber bundle. A regular-shaped cylinder is fixed on the clapper. The cylinder is perpendicular to the neat end surface of the fiber bundle. The cylinder can also be a cylinder or an ellipse. It can also be a square tube, it can be a combination of the above-mentioned tubes, or it can be a cylindrical structure with no closed shape in the above-mentioned shapes. One clapper can satisfy multiple fiber supply containers. The tubes on the clapper match the number of fiber supply containers. The cylinder can be put into one end of the fiber supply container which relies on the neat surface of the fiber bundle; the contact part of the clapper and the neat end of the fiber bundle can be pasted with rough surface materials, and the roughness of the contact part can be caused by the material of the clappe...

Embodiment 3

[0048] Embodiment 3: as figure 1 , 3 , 4 and 5, the placement angle of the fiber supply container enables the fiber bundle to displace toward the clapper device due to gravity, when the fiber bundle is taken out from the fiber supply container, the fiber bundle can be directly taken out from the fiber supply container, and the fiber supply can be The container is turned upside down to pour out the fiber bundles, and the fiber bundles can also be drawn out from one end of the fiber supply container. The fiber supply container can be arranged on one side or both sides of the clapper. One movement cycle of the clapper can supply the fiber bundles inside the container to the fibers on each side. Complete a neat slap on the end face.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com