Production process for preparing N-phosphonomethyl iminodiacetic acid

A production process, the technology of diglyphosate, which is applied in the production process of diglyphosate, can solve the problems of excess hydrochloric acid, etc., and achieve the effects of optimizing the environment, saving costs, and reducing heavy process wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

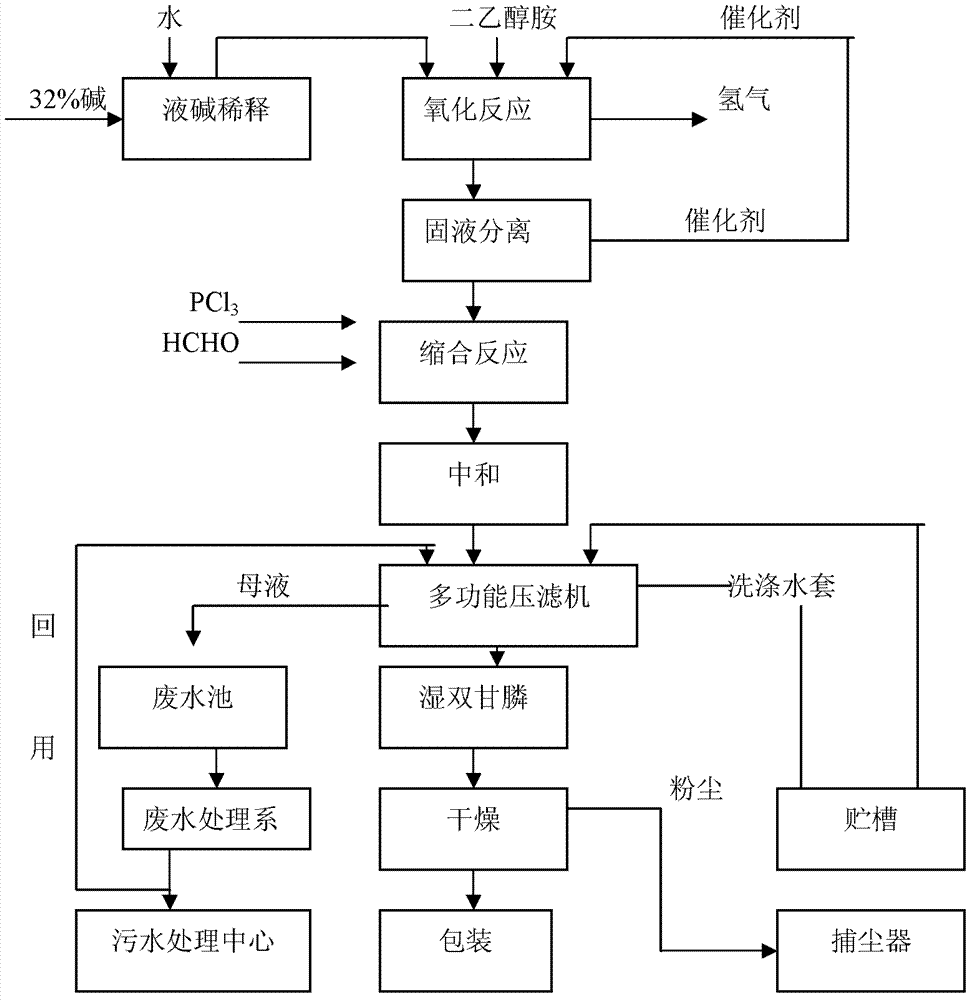

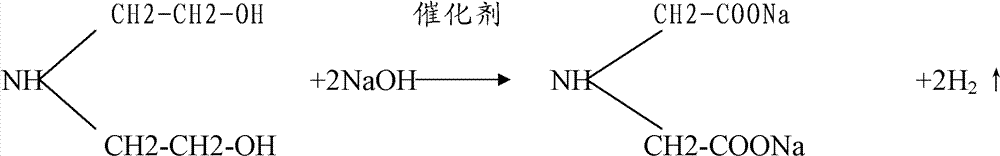

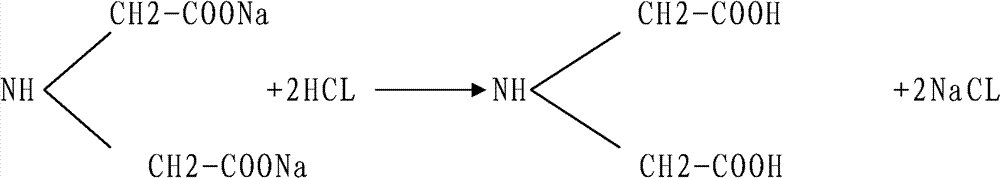

[0024] A production process for preparing diglyphosate, comprising dehydrogenating diethanolamine to form iminodiacetic acid disodium salt, and then condensing it with phosphorus trichloride and formaldehyde to obtain diglyphosate; specifically comprising the following steps:

[0025] ① Control the weight percent concentration of iminodiacetic acid disodium salt to 24%-28%, then add phosphorus trichloride under vacuum conditions, and the reaction temperature is 65°C-70°C, in which iminodiacetic acid disodium The mol ratio of salt, phosphorus trichloride is 1: 1.04-1.06;

[0026] ②Then add the iminodiacetic acid disodium salt that the weight percent concentration is 24%-28%, the amount of the iminodiacetic acid disodium salt added at this moment is 1. the iminodiacetic acid disodium salt in the step 1.5 times the amount;

[0027] 3. adding weight percentage concentration is 35%-40% formaldehyde to carry out condensation reaction again, and the amount of formaldehyde is 1.25-1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com