Coaxial jet head for electro-hydrodynamic jet printing and application thereof

A technology of coaxial nozzles and electrofluids, which is applied in printing and other directions, can solve the problems of repeatability in the spinning process of precise positioning, the inability to realize electrospinning, and the inability to facilitate probes, so as to avoid the inability to realize continuous jet printing and promote The formation of Taylor cone, the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

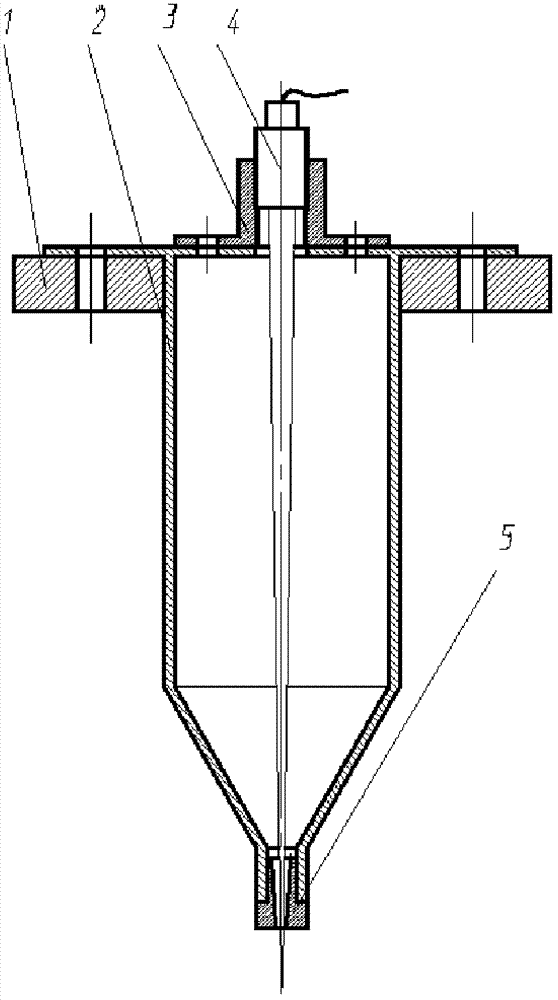

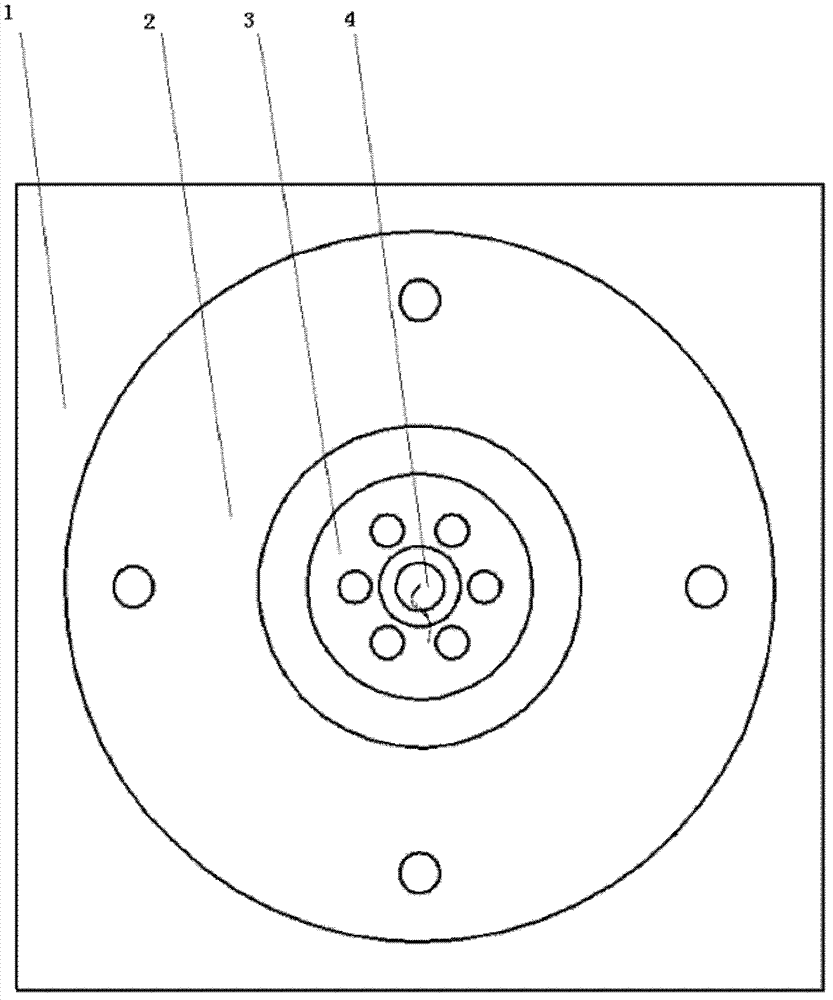

[0029] Such as Figure 1-6 As shown, an electrohydrodynamic jet printing coaxial nozzle of the present invention includes a probe placement platform 1 , a nozzle 2 , a support seat 3 , a metal probe 4 , and a lip sleeve 5 .

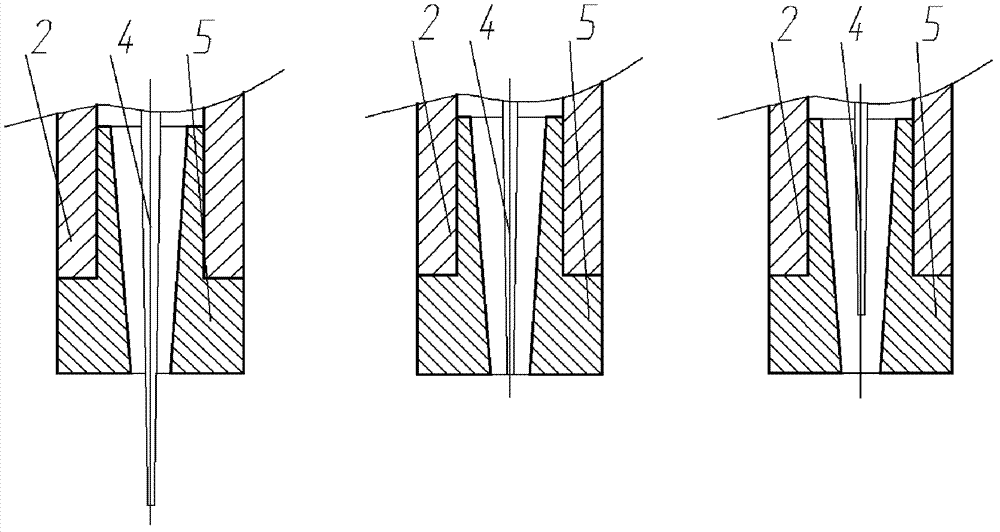

[0030] The nozzle 2 is fixed on the probe placement platform 1, the support seat 3 is installed on the upper end of the nozzle 2, the lip cover 5 is set on the nozzle at the lower end of the nozzle 2, and the upper needle end of the metal probe 4 is set on the support seat 3. In the central threaded hole, the needle body is placed in the inner cavity of the nozzle 2, the axis of the needle body is coaxial with the central axis of the nozzle 2, and the needle tip of the lower part of the probe passes through the inner through hole of the lip sleeve 5 and protrudes out of the nozzle 2.

[0031] The metal probe 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com