Automatic Blade Measuring Machine

A measuring machine and fully automatic technology, which is applied in sorting and other directions, can solve the problems of production efficiency, poor stability, and large errors that affect product quality, and achieve the goals of saving manpower and time, improving efficiency, and ensuring accuracy and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

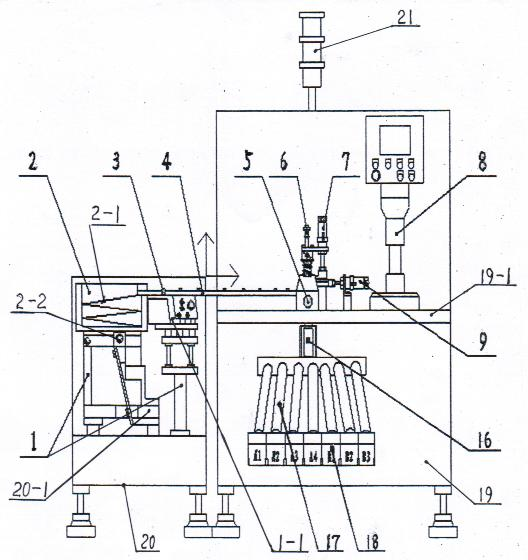

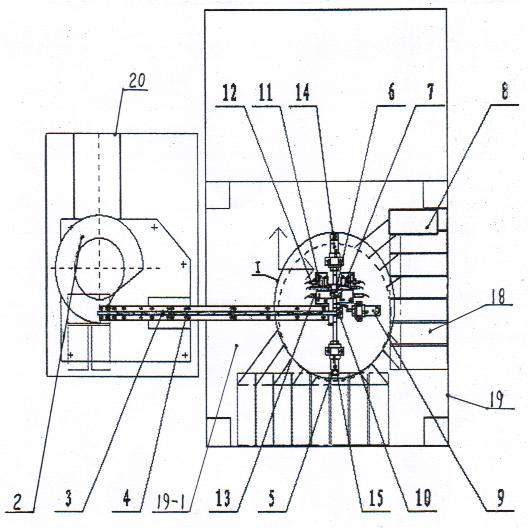

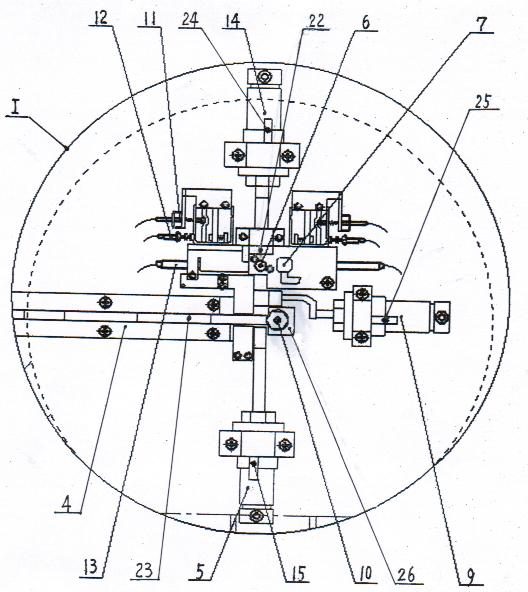

[0011] Examples, see attached Figure 1~3 , a chassis 20-1 is provided in the vibrating feeding cabinet 20 of the full-automatic blade measuring machine, and a support frame 1 is provided on the top and right side of the chassis 20-1, and a spiral vibrating plate 2 and a feeding plate frame 1- are mounted on the support frame 1. 1. Fix the feeding plate 4 on the feeding plate frame 1-1, and set the sensor-3 on one side of the feeding plate 4. Set the feeding controller 2-2 under the spiral vibrating plate 2, install the spiral feeding track 2-1 in the spiral vibrating plate 2, set three selection gaps on the feeding track 2-1, pass three screenings, and turn the R side up The blades 23 are delivered to the feeding plate 4. The left end of feeding plate 4 is connected with three selection gaps provided on the feeding track 2-1, and the right end of feeding plate 4 is connected with the sensor seat 26 top in the measuring cabinet 19. Sensor two 10 are established above the sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com