Anti-loosening alarm device for vibrating screen

A technology of alarm device and screen mesh, which is applied in the direction of measuring device, electric device, filter screen, etc., to reduce the mixing rate and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

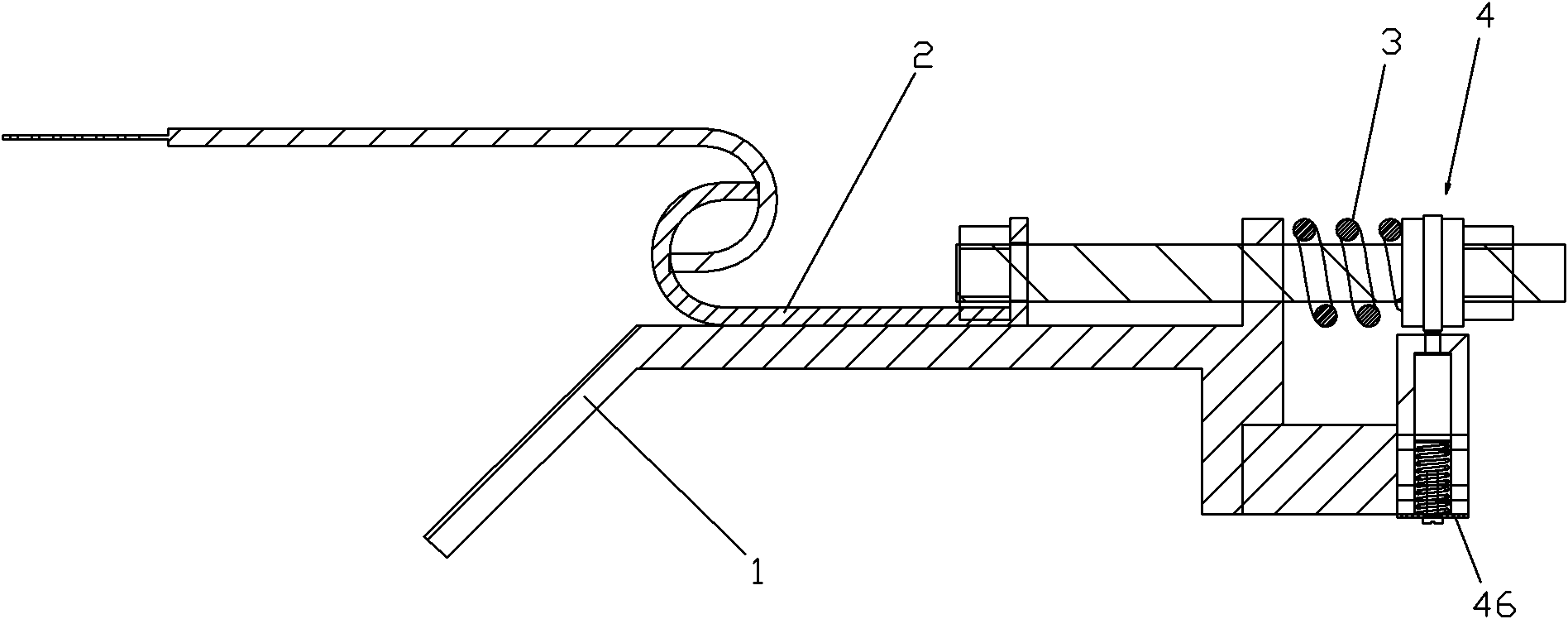

[0018] refer to figure 1 and figure 2 , a vibrating screen anti-loose alarm device of the present invention, comprising a screen fixed support frame 1, a screen tensioning device 2 and a screen compression spring 3, the screen fixed support frame 1 and the screen tensioning device A contact-type macro-distance measurement sensor 4 is arranged between the two, and a detection and alarm circuit 5 is connected to the signal output of the contact-type macro-distance measurement sensor 4 .

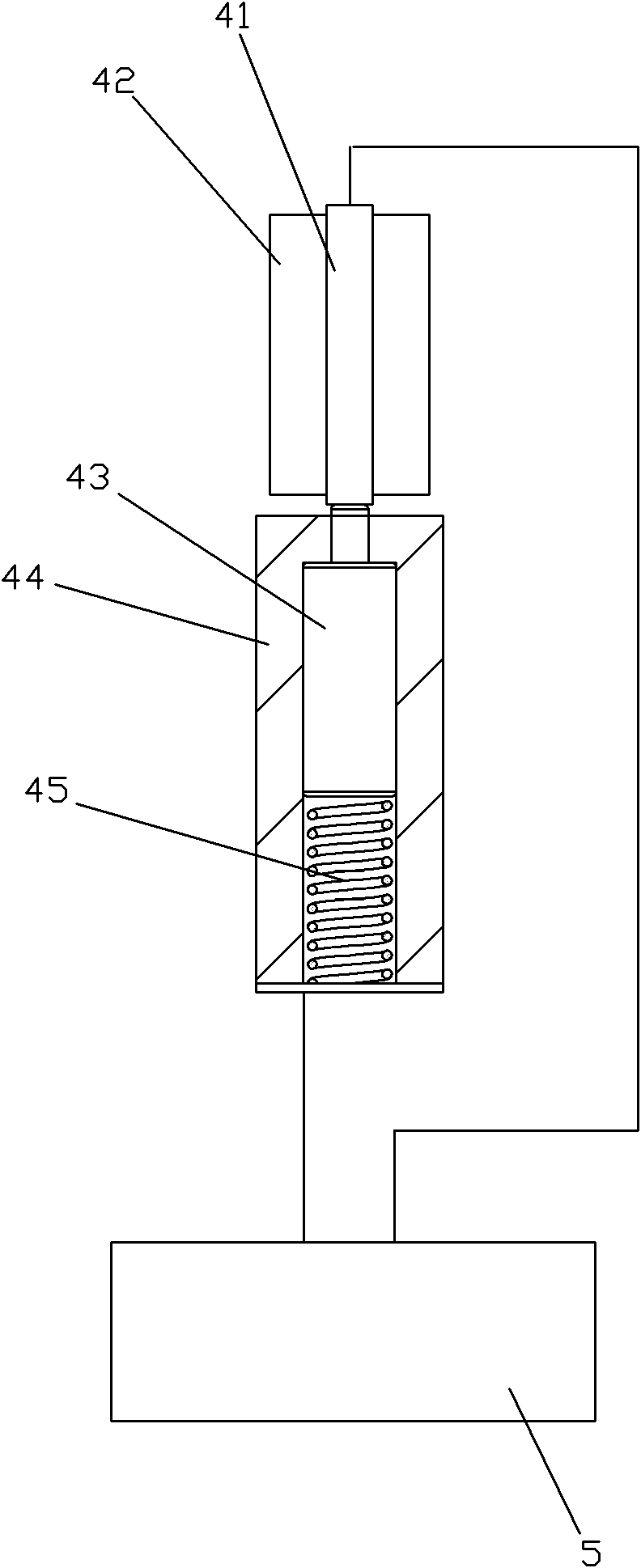

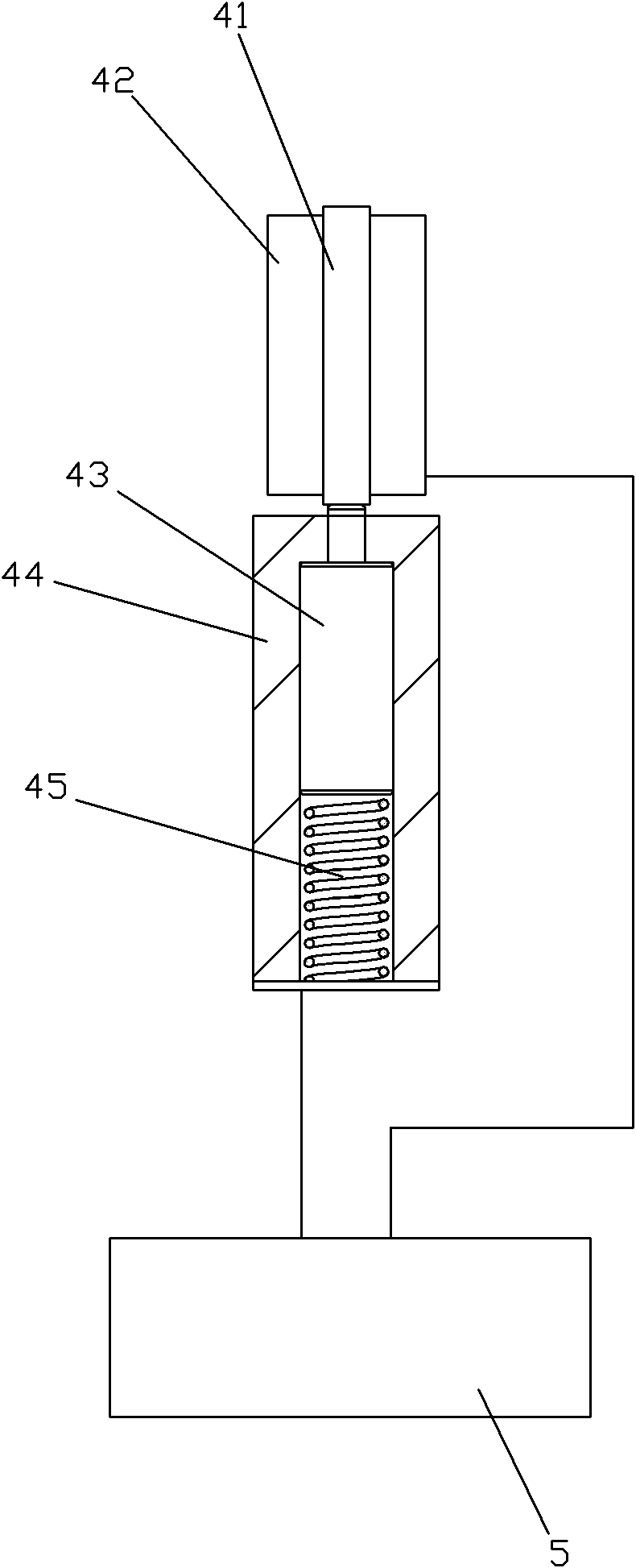

[0019] Contact macro measuring sensor 4 comprises upper end 41, lower end 43, thrust spring 45, spring cover 46, upper end shell 42 and lower end shell 44; , the upper shell 42 is an insulator, and the upper end 41 is insulated from other parts of the vibrating screen by the upper shell 42; the lower end 43, the thrust spring 45, the spring cover 46 and the lower shell 44 are installed on the screen fixed support frame 1, and the lower end 43 is a conductor. Lower end casing 44 is an insulat...

Embodiment 2

[0023] refer to figure 1 and image 3 , a vibrating screen anti-loose alarm device of the present invention, comprising a screen fixed support frame 1, a screen tensioning device 2 and a screen compression spring 3, the screen fixed support frame 1 and the screen tensioning device A contact-type macro-distance measurement sensor 4 is arranged between the two, and a detection and alarm circuit 5 is connected to the signal output of the contact-type macro-distance measurement sensor 4 .

[0024] The contact macro measuring sensor 4 comprises an upper end 41, a lower end 43, a thrust spring 45, a spring cover 46, an upper shell 42 and a lower shell 44; the upper end 41 and the upper shell 42 are installed on the screen tensioning device 2, and the upper end 41 is an insulator , the upper shell 42 is a conductor, and the upper shell 42 is electrically connected to other parts of the vibrating screen; the lower end 43, the thrust spring 45, the spring cover 46 and the lower shell ...

Embodiment 3

[0027] refer to Figure 4 , a vibrating screen anti-loose alarm device of the present invention, comprising a screen fixed support frame 1, a screen tensioning device 2 and a screen compression spring 3, the screen fixed support frame 1 and the screen tensioning device An eddy current displacement sensor 6 is arranged between the two, and the signal output of the eddy current displacement sensor 6 is connected with a detection and alarm circuit. The detection end 61 of the eddy current displacement sensor 6 points to a detection background module 62, and the eddy current displacement sensor 6 and the detection background module 62 are respectively fixed on the screen fixed support frame 1 and the screen tensioning device 2, when the vibrating screen is loose or vibrates When the sieve warp line breaks, the tension of the sieve decreases, and the tension of the sieve compression spring 3 is greater than the tension of the sieve. The sieve compression spring 3 drives the detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com