tube target

A tube target and carrier tube technology, which is applied in the field of tube targets, can solve problems such as damage, no longer covering, and target damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

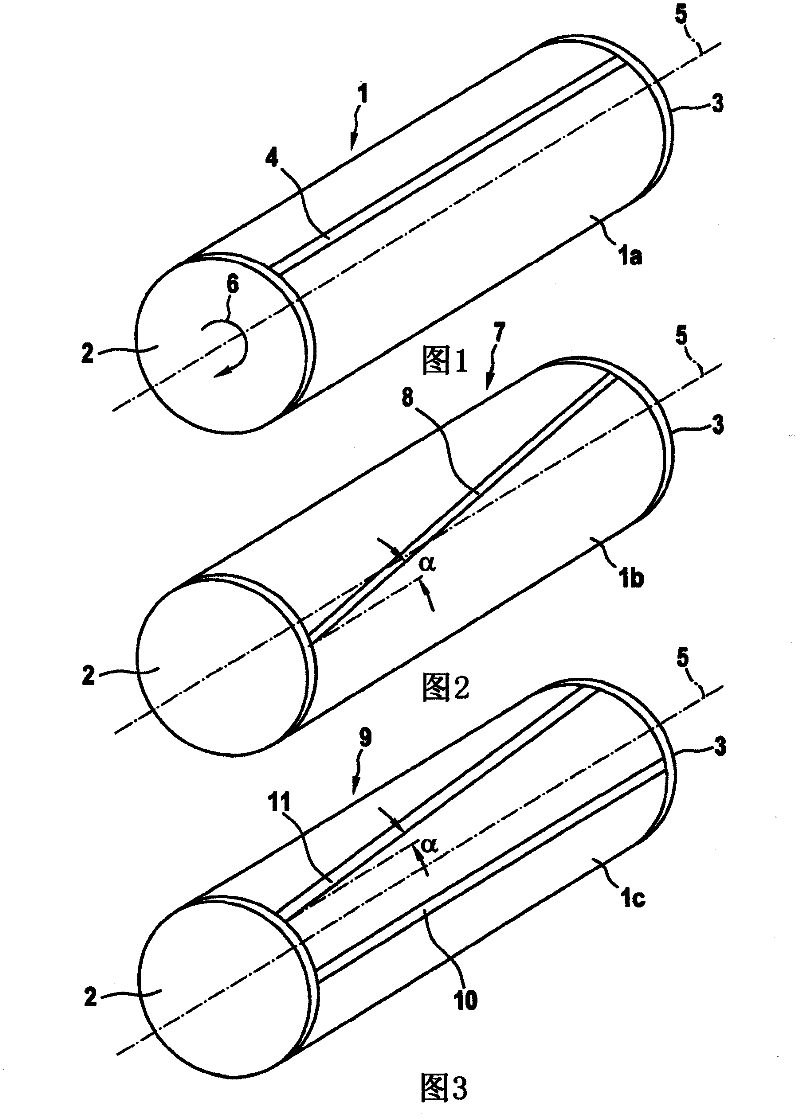

[0029] exist figure 1 The tube target 1 is shown schematically in a perspective view. For the sake of simplicity, the tube target is closed here with caps 2 , 3 . Tube Target 1 has the figure 1 The carrier tube surrounded by the target 1a is not visible in . The target 1 a is provided with a groove 4 which extends parallel to the axis of rotation 5 of the tube target 1 . The direction of rotation is indicated briefly by arrow 6 . The depth of the groove 4 is not fixed.

[0030] A plasma is present during the sputtering process above or below a portion of the tube target 1 . The plasma is substantially as long as the tube target 1 , but has a diameter smaller than the diameter of the tube target 1 . If the tube target 1 is rotated, the slot 4 is above or below the plasma for the entire length of the slot during the under or over coating of the plasma. The slot 4 immersing in the plasma, staying in the plasma or leaving from the plasma changes the plasma-facing surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com