A kind of micro-twisted mirror of trench isolation anchor point comb teeth and its manufacturing method

A technology of trench isolation and micro-torsion mirror, which is applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problem of difficult and accurate measurement of comb capacitance, and achieve novel design methods, remarkable effects and reliable performance Effects of Sex and Accuracy Guarantees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

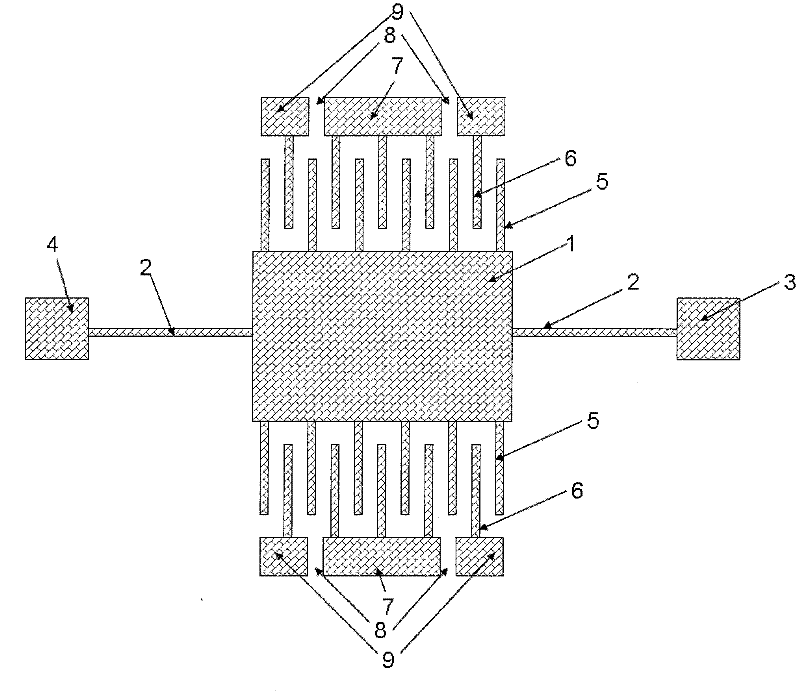

[0021] Refer to figure 1 , The groove-isolated micro-torsion mirror of the anchor point comb tooth in this embodiment includes a mirror surface which is respectively suspended on the power-on lead anchor point 4 and the test lead anchor point 3 through two supporting beams 2; The two groups of movable comb teeth 5 on the side respectively form a comb pair with two groups of fixed comb teeth 6 located on two fixed anchor points; it is characterized in that the fixed anchor points are separated into three by two fixed anchor point isolation grooves 8. Part: the isolated power lead anchor point 7 in the middle part and the isolated test lead anchor point 9 on both sides; the fixed comb teeth 6 on the isolated power lead anchor point 7 and the corresponding movable comb teeth 5 constitute A pair of driving comb teeth; the fixed comb teeth 6 on the isolated test lead anchor 9 and the movable comb teeth 5 corresponding thereto constitute a detection comb tooth pair.

[0022] In order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com