Water lubricated bearing and transmission system comprehensive performance testing platform

A water-lubricated bearing and comprehensive performance technology, which is applied in the field of water-lubricated bearings and its transmission system comprehensive performance testing experimental platform, can solve the problems of inability to accurately measure water film pressure, imperfect comprehensive performance testing methods, and lack of water-lubricated bearings and transmission systems. System performance testing and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

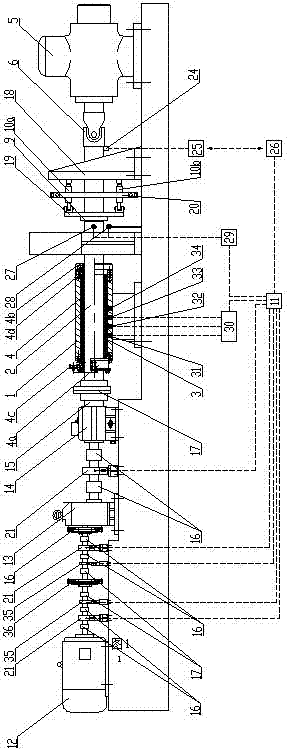

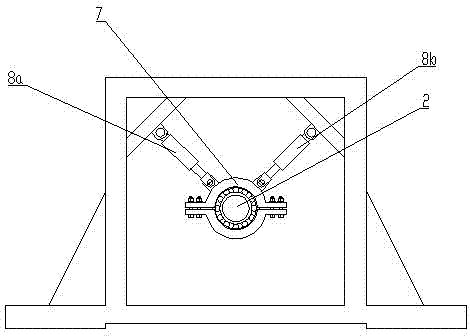

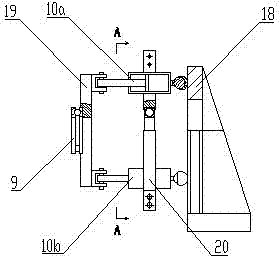

[0033] The present invention will be described in detail below in conjunction with accompanying drawing, figure 1The dotted line in the figure represents the transmission of detection signals or the data transmission after signal processing, as shown in the figure: the water-lubricated bearing and transmission system comprehensive performance experiment platform of this embodiment includes bearing housing 1, test shaft 2 passing through bearing housing 1, The test shaft rotation driving device and the test shaft loading device are respectively arranged on both sides of the bearing seat 1 along the axial direction of the test shaft 2, and a bearing test cabin for installing a water-lubricated bearing 3 is formed between the bearing seat 1 and the test shaft 2 4. The two ends of the bearing test cabin 4 are respectively sealed with dynamic sealing device I4a and dynamic sealing device II4b, and water inlet 4c and water outlet 4d are installed; the above-mentioned components are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com