Manioc waste residue drying device and device for manufacturing firewood bar and charcoal

A drying device and cassava technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of high cellulose and difficulty in one-time drying, achieve high utilization rate, prolong hot air utilization time, and heat energy less loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Example 1 (drying device for cassava waste residue)

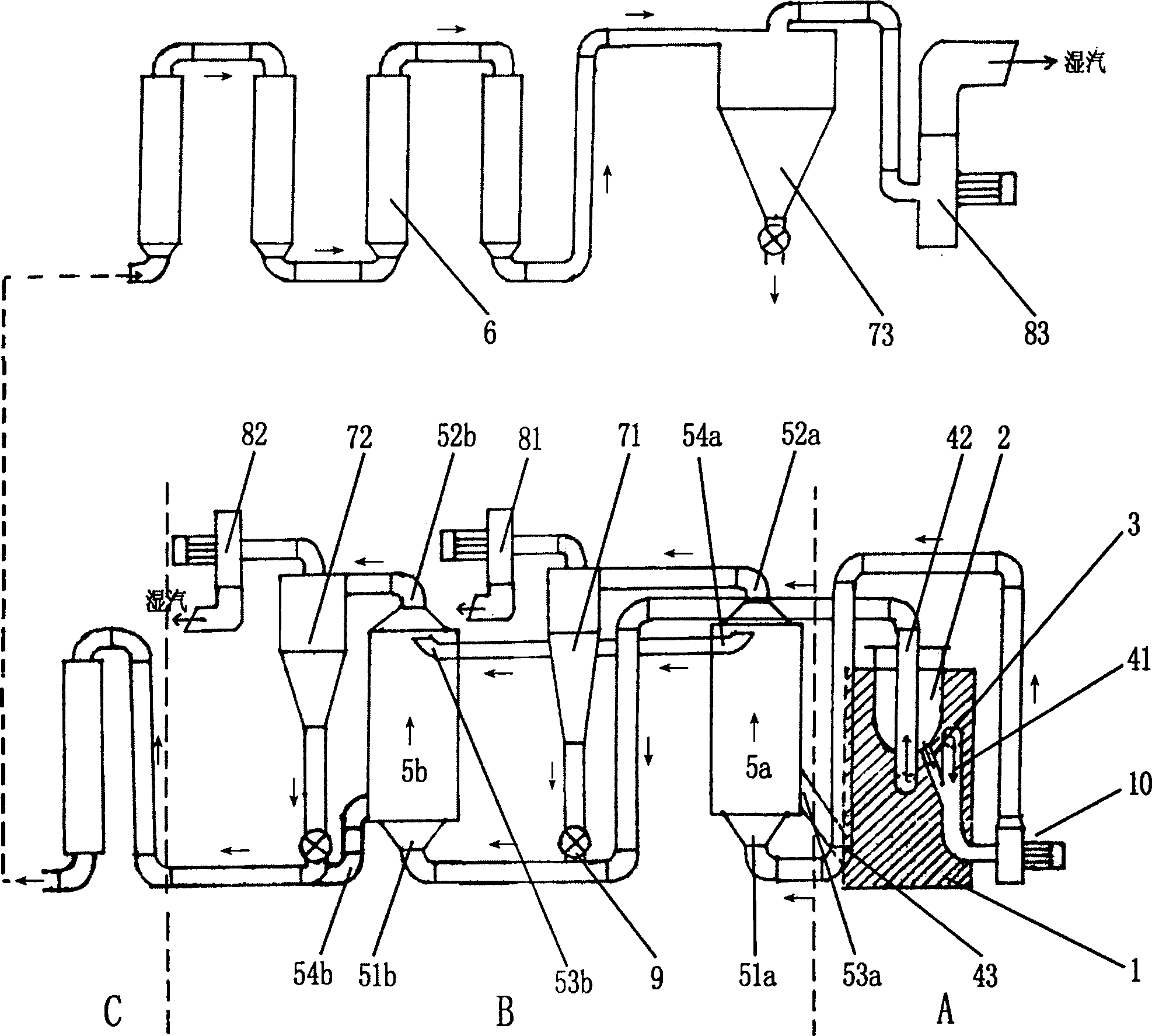

[0048] figure 1 It is a structural schematic diagram of an embodiment of the cassava waste residue drying device of the present invention. Such as figure 1 The shown cassava waste residue drying device is composed of a throwing type pre-drying section A connected in sequence, a pre-stage gas-solid separation drying section B and a post-stage gas-material mixing hot air drying section C; wherein,

[0049] (1) The throwing type pre-drying section A: includes a horizontal drying chamber 2 and a furnace 1 positioned below the drying chamber 2; the upper part of the drying chamber 2 is provided with a cassava wet slag feed port ( figure 1 not shown), the bottom is provided with a powdery wet material outlet 3; the furnace 1 is provided with three hot air outlets 41, 42 and 43; the powdery wet material outlet 3 and one of the hot air outlets 41 of the furnace 1 They are all connected to the inlet of the pre-stag...

Embodiment 2

[0054] Two, embodiment 2 (cassava waste residue drying device)

[0055] The structure of the cassava waste residue drying device of this embodiment is roughly the same as that of Embodiment 1, except that the blower fan 10 is a blower.

Embodiment 3

[0056] Three. Embodiment 3 (drying device for cassava waste residue)

[0057] The structure of the cassava waste residue drying device of this embodiment is roughly the same as that of Embodiment 1, the difference being that: on each hot blast outlet pipeline of the furnace 1 and on the interlayer hot blast inlet pipeline with interlayer dryers 5a and 5b, an air volume control is provided. The valve is used to control the heat supply so that the temperature of the hot air passing through the interlayer of each interlayer drier is higher than the temperature of the hot air passing through the corresponding inner cavity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com