Core breaking mechanism

A technology of cores and circlips, which is applied in the field of core lifting and breaking mechanisms, can solve problems affecting the accuracy of sampling analysis, poor quality, time-consuming and labor-consuming core quality, etc., and achieve the effects of simple structure, convenient replacement, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

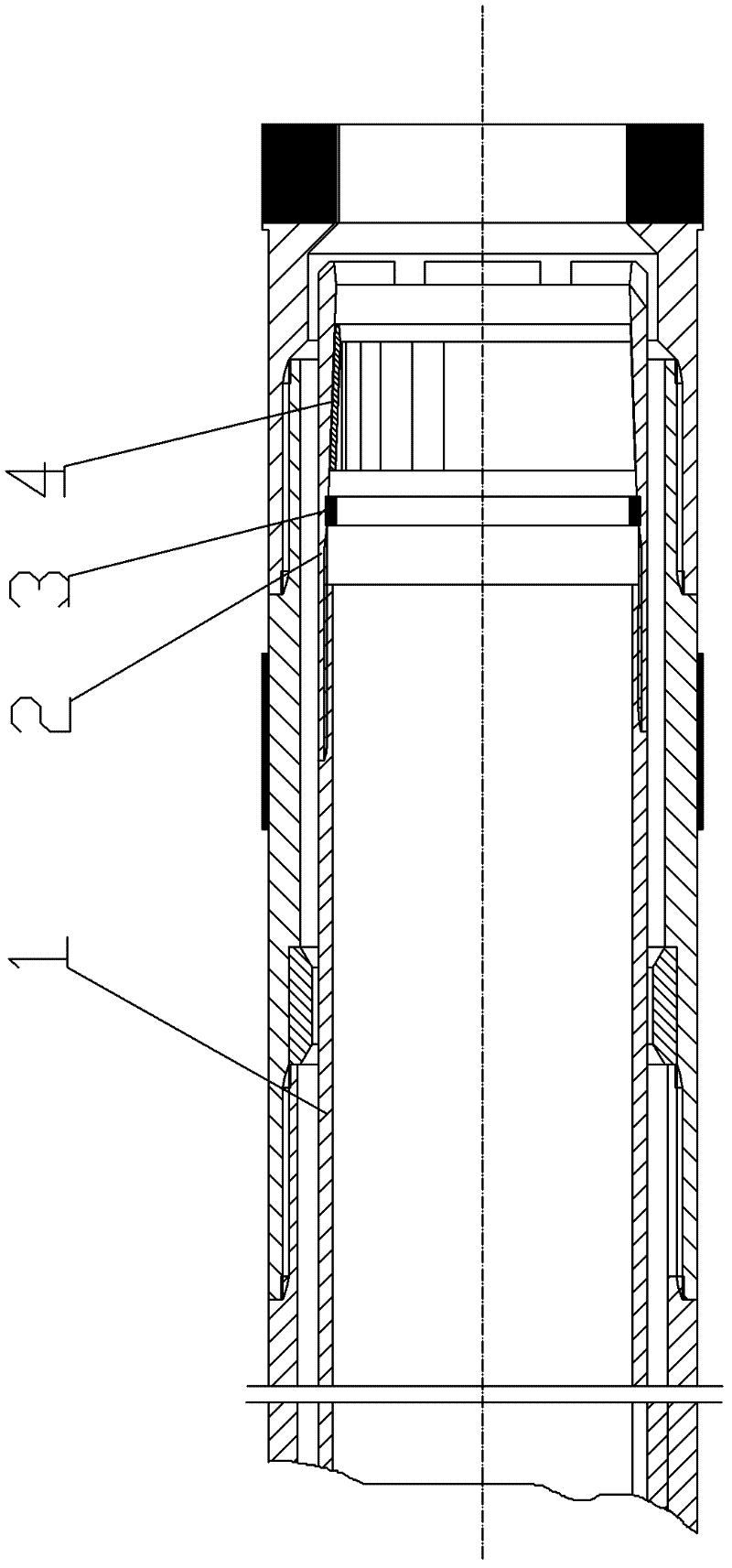

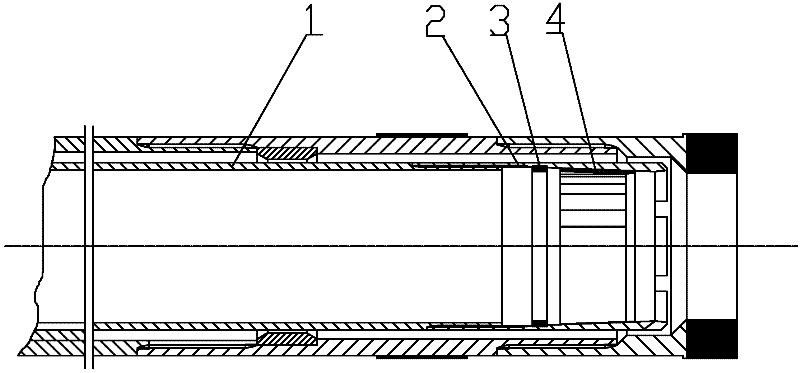

[0010] Such as figure 1 Shown: including inner tube 1, retaining ring seat 2, retaining ring 3 and retaining spring 4.

[0011] Described jump ring seat 2 and inner pipe 1 are connected by thread, and jump ring 4 is close to in the ring ring seat 2 by its own elastic tension, and there is retaining ring 3 at the joint with inner pipe 1 to block and play the effect of stopping back. When the drill bit is drilling, the rock core goes up through the retaining spring 4, the retaining ring 3, and reaches the inner tube 1; The circlip 4 of the groove is affected by the elastic force and blocks the rock core and cannot go up, and the joint between the circlip 4 and the circlip seat 2 has a certain taper. Under the action, the core breaks here, and the inner tube can smoothly extract the sample.

[0012] Working process of the present invention

[0013] 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com