Center-through cylindrical foundation and its installation process

A technology of cylindrical foundation and installation technology, which is applied in the direction of basic structure engineering, construction, etc., can solve the problems of difficult pressure control in the cylinder, the inability to ensure the smooth penetration of the cylindrical foundation, and the inability to accurately position the cylindrical foundation, etc., to reduce the The effect of base size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

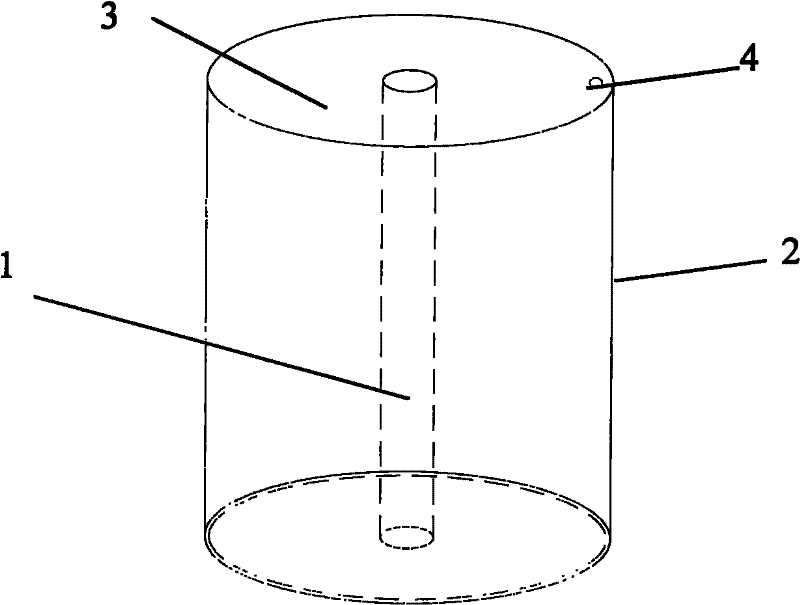

[0033] like figure 2 As shown, the present invention comprises a cylindrical basic body 2 with a closed upper end and an open lower end, and a pumping hole 4 is provided on a closed top cover 3 of the cylindrical basic body 2; The cylinder wall 1 and the inner cylinder wall 1 are up and down through-type structures.

[0034] The present invention adopts following installation steps:

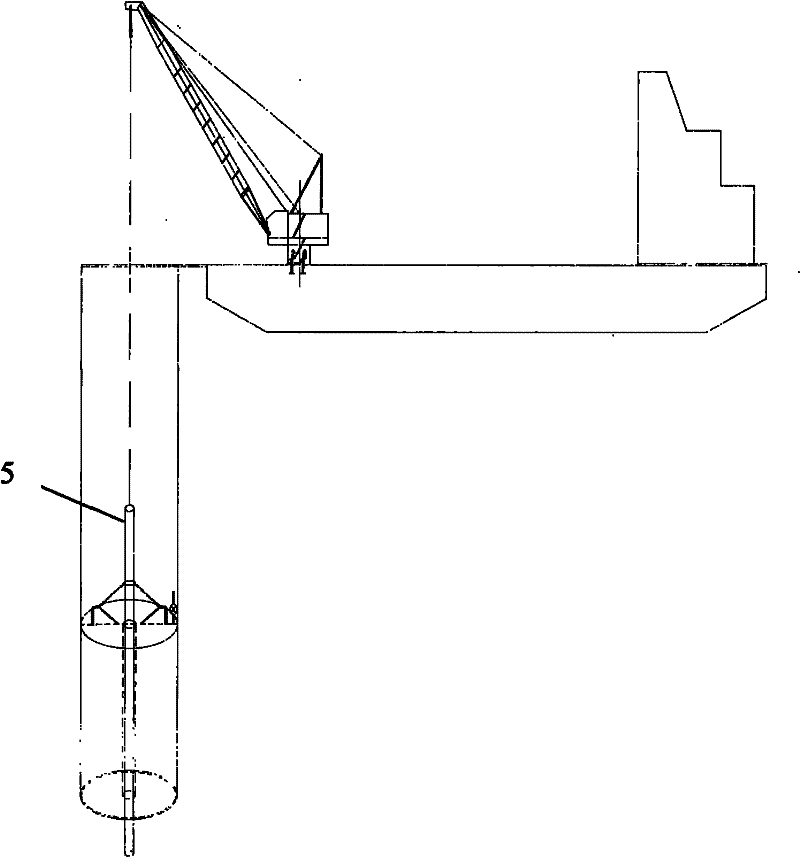

[0035] first step, such as image 3 As shown in , the workboat is towed or self-propelled to the construction site, and is accurately positioned by the GPS positioning system and positioning equipment;

[0036] In the second step, use the hoisting device installed on the workboat to hoist the central-type cylindrical foundation and the positioning short pile 5 to the seabed; the hoisting device in this embodiment is a crane.

[0037] In the 3rd step, utilize the level meter 7 that is located on the cylindrical foundation to measure the horizontal condition of the cylinder top, then, utilize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com