Sludge dehydrator

A sludge dewatering machine and sludge pump technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of difficult to maintain pressure in the filter press chamber, odor emission, and high cost, and achieve a short path through and liquid drainage. The effect of low resistance and short discharge time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

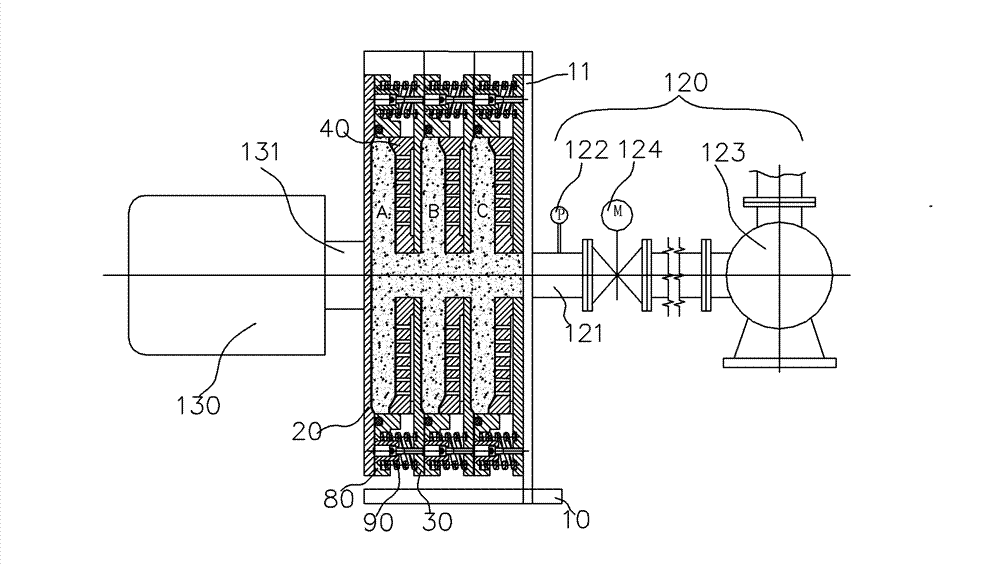

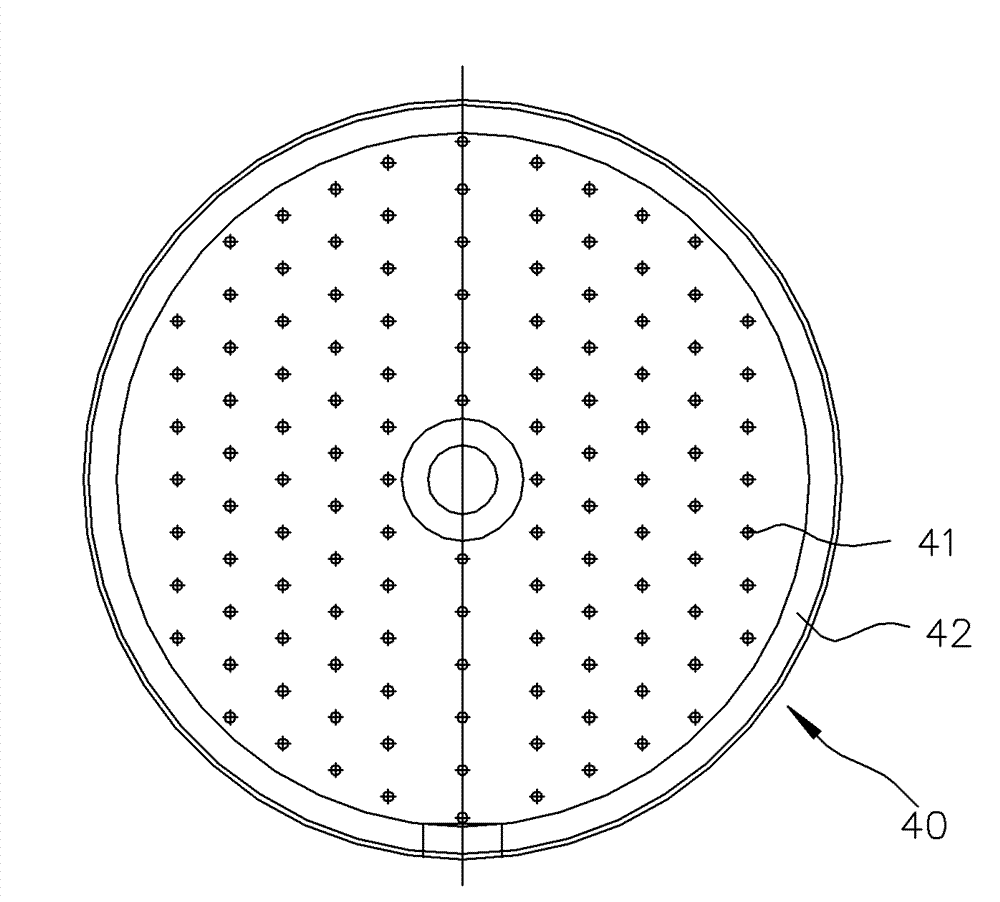

[0011] Such as figure 1 , 2 , a sludge dewatering machine, comprising a frame 10 and a connection support plate 11 fixedly connected with the frame 10, a sludge pumping mechanism and a pressure extrusion mechanism are respectively arranged on both sides of the body of the connection support plate 11, and the pressure extrusion mechanism A frame-plate type filter press mechanism is arranged between the connecting support plate 11, and the frame-plate type filter press mechanism includes a filter press unit composed of front and rear press plates 20, 30, and the filter press unit also includes a filter press unit between the front and rear press plates 20, 30. The filter plate 40 is set, the outer peripheral wall of the filter plate 40 is covered with an annular sleeve 80 and a sliding fit is formed between the two. A spring 70 is arranged between the side end surface and the rear pressure plate 30 to drive the two to separate, and the space enclosed between the filter plate 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com