Spiral dosing mechanism and dosing method thereof

A screw and screw technology, which is applied in the field of drug feeding of the screw drug feeding mechanism, can solve the problems of large measurement error, slow speed, cross contamination of drugs, etc., and achieve the effects of resource saving, convenient use, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the accompanying drawings.

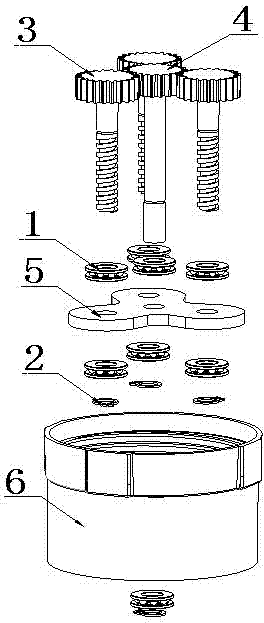

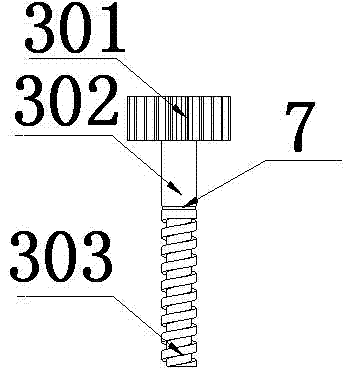

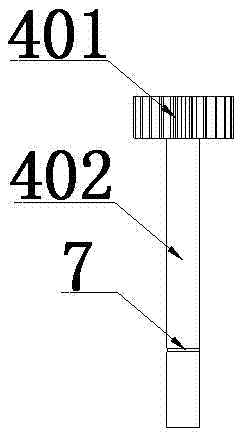

[0016] like Figures 1 to 4 As shown, a screw feeding mechanism includes a thrust ball bearing 1, a bearing retaining spring 2, 3 feeding screws 3, a motor rotating shaft 4, a screw support plate 5, and a feeding part 6; the feeding screw 3 is composed of a screw gear 301 and The screw shaft 302 is composed of a screw shaft 302, one end of the screw shaft 302 is fixedly connected with the screw gear 301, a spring groove 7 is arranged in the middle part, and a spiral medicine groove 303 is arranged on the surface of the screw shaft 302 below the spring groove 7; the motor rotating shaft 4 is rotated by A shaft gear 401 and a motor shaft 402 are formed. One end of the motor shaft 402 is connected to the motor, and the other end is connected to the rotating shaft gear 401. A spring groove 7 is arranged in the middle and lower sections of the motor shaft 402; a circular hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com