Water-sealed ring cooler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

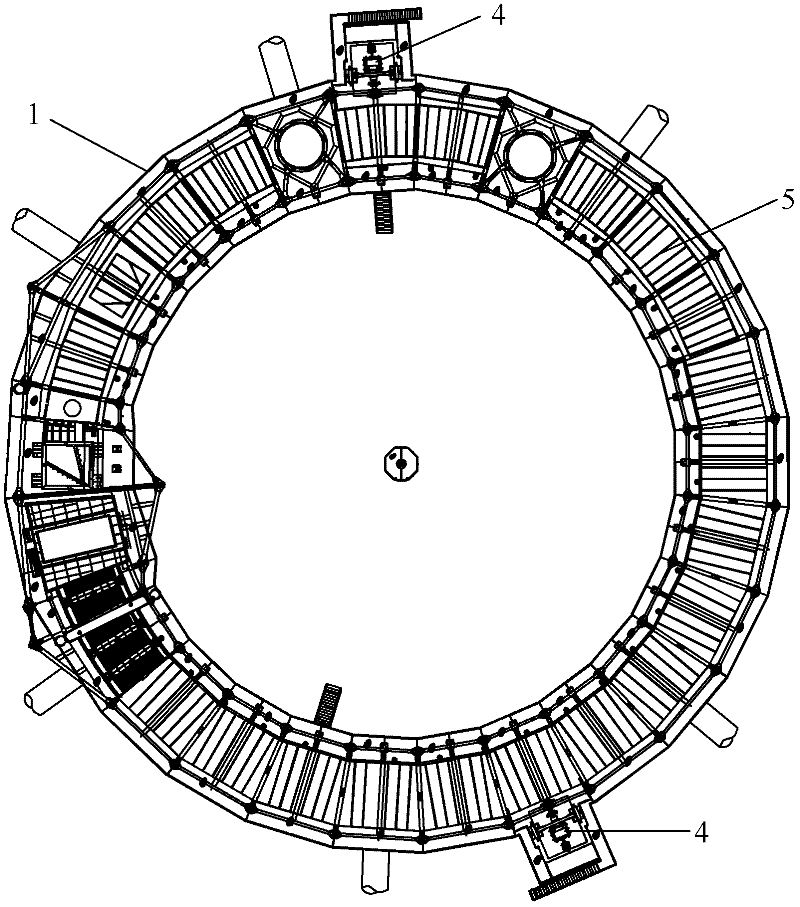

[0038] As shown in the figure, the water-sealed annular cooler of the present invention includes:

[0039] body 1;

[0040] A slewing system, arranged on the machine body 1, includes a rotary power drive device 4 and a rotary frame 5 that rotates under the drive of the rotary power drive device 4;

[0041] The trolley 2 is set on the revolving frame 5;

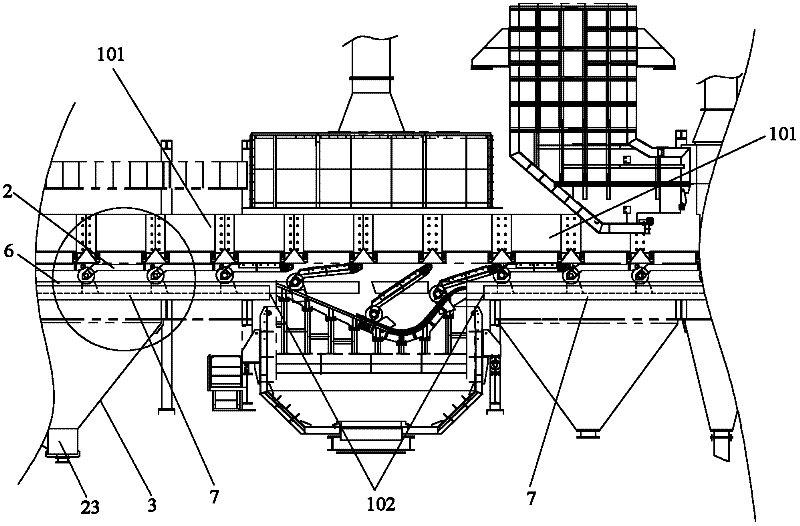

[0042] The air blowing system is placed under the revolving frame 5, including a blower 23 and a bellows 3 arranged between the air outlet of the blower 23 and the revolving frame; and,

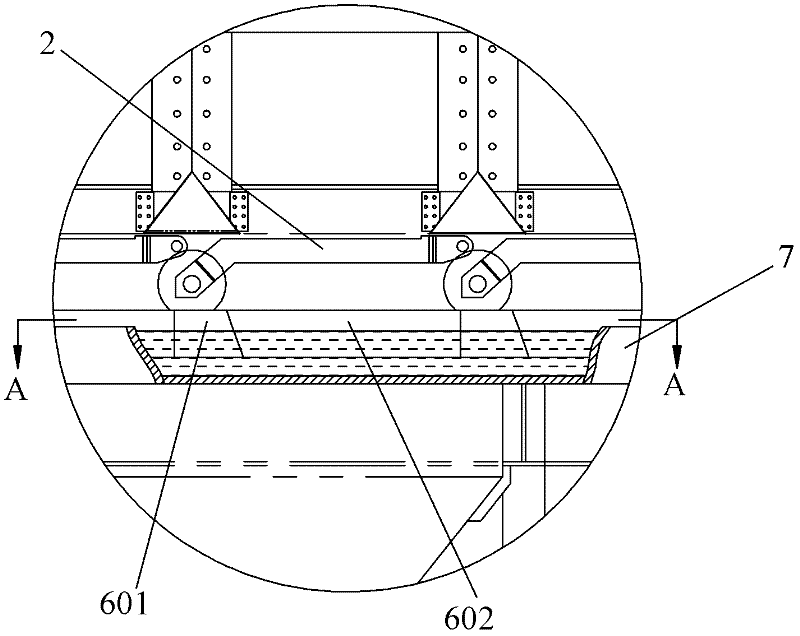

[0043] The water sealing device is composed of two sets of water seals with the same structure, which are respectively arranged on the outer ring side and the inner ring side of the trolley 2 and / or the rotary frame 5 rotating circular track (such as Figure 6 shown), and between the bellows 3 and the trolley 2 and / or the revolving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com