A gear selection actuator of an electronically controlled mechanical automatic transmission

An automatic transmission and actuator technology, applied in the field of machinery, can solve problems such as complex structure and reduced reliability, and achieve the effects of simple structure, reduced power interruption time, and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

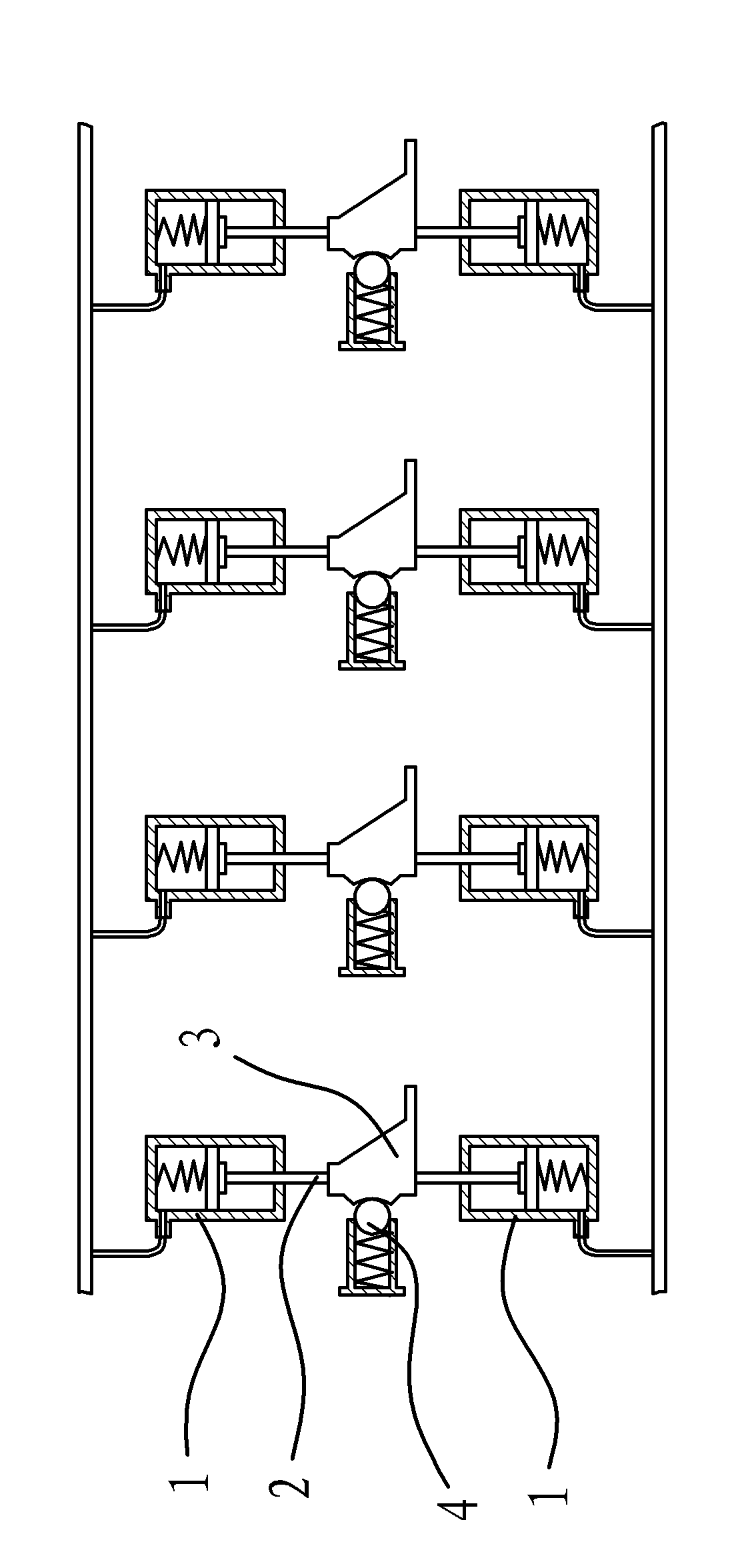

[0024] Such as figure 1 As shown, the gear selection actuator of the electronically controlled mechanical automatic transmission is arranged at the shift lever of the automatic transmission. It includes a plurality of shifting parts located between two adjacent shift rods. The shifting parts are provided with oil cylinders 1, and the plurality of oil cylinders 1 are all connected through hydraulic pipelines.

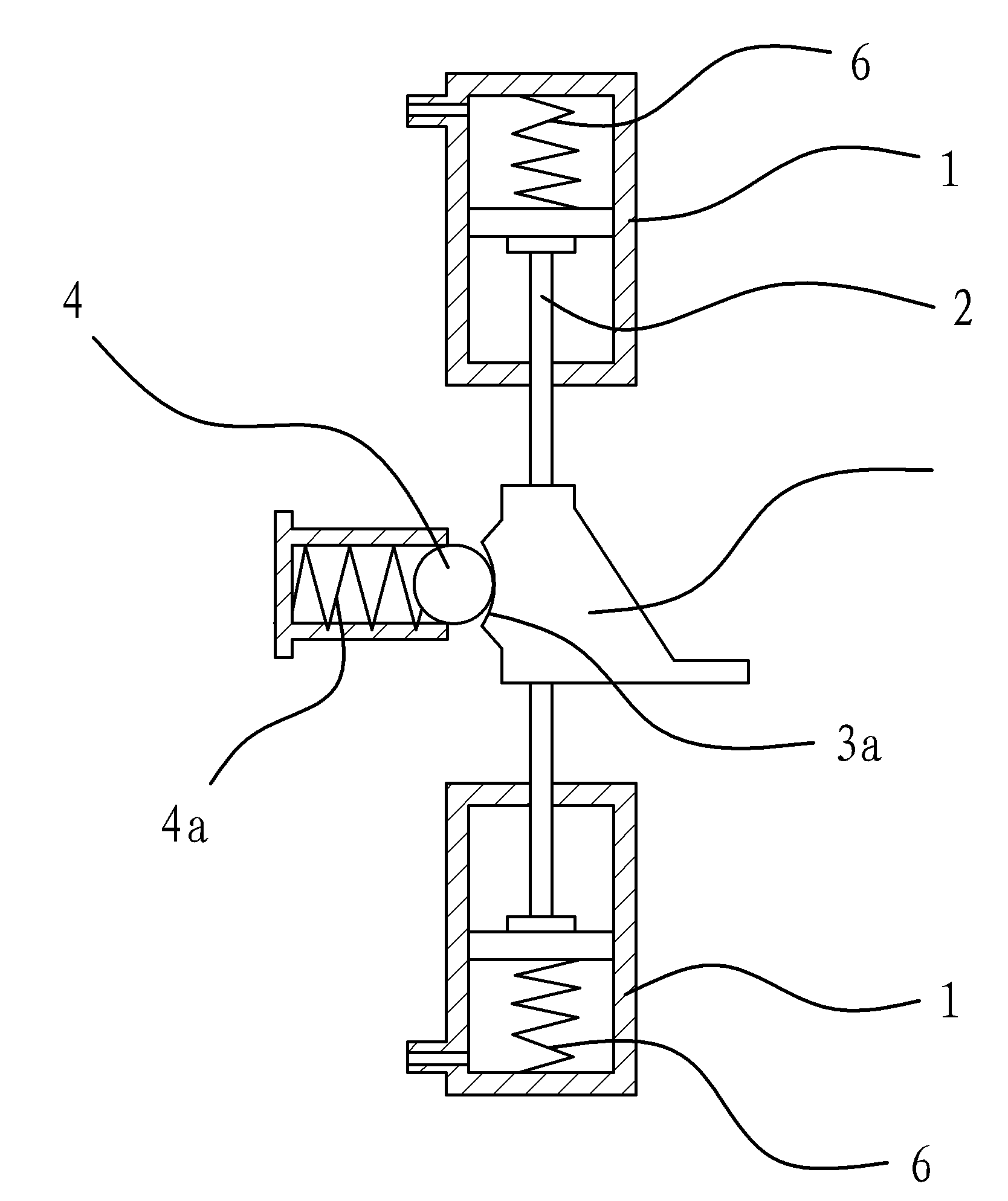

[0025] Such as figure 1 and figure 2 As shown, the shifting member is two oil cylinders 1 and a piston rod 2 located between the two oil cylinders 1, and the two ends of the piston rod 2 are located in the above two oil cylinders 1 respectively. On the piston rod 2, there is a shift fork 3 capable of shifting the shift lever, and the above-mentioned several oil cylinders 1 are all connected through hydraulic pipelines.

[0026] There is a locking pin 4 on the gearbox, and a locking spring 4a is provided at the locking pin 4, and the locking pin 4 is embedded on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com