Low pressure oil well liquid level automatic monitoring device

An automatic monitoring and automatic control device technology, applied in the direction of measurement, wellbore/well components, earthwork drilling and production, etc., can solve the problems that affect the popularization and promotion of automatic liquid level monitoring, low reliability, high equipment price, etc., and achieve weight Lightweight, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

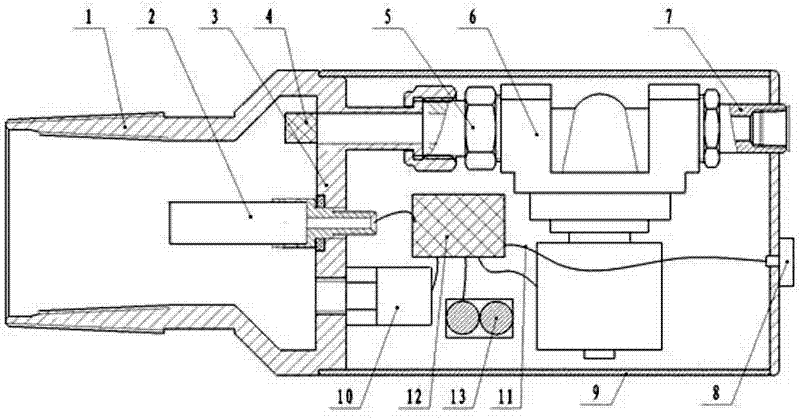

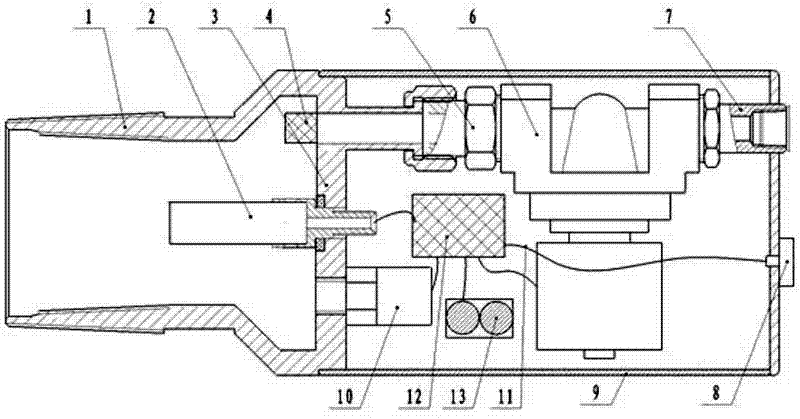

[0017] Such as figure 1 As shown, a low-pressure oil well liquid level automatic monitoring device includes a protective cover housing 9, a partition 3, an oil well casing connection interface 1, an automatic control device 12, a microphone 2 and a pressure sensor 10, and the protective cover housing 9 There is a gas sound wave generating device inside, the front end communicates with the outside of the partition 3, and the rear end communicates with the outside of the protective cover shell 9; a pressure sensor 10 is arranged inside the partition 3, and the automatic control device 12 communicates with the micro Sounder 2, pressure sensor 10 and gas sound wave generating device are connected.

[0018] The gas sound wave generating device includes a solenoid valve 6, a filter 4, a connector 5 and an exhaust port 7, the inlet end of the solenoid valve 6 is connected to the connector 5, and the gas outlet end of the solenoid valve 6 is connected to the exhaust port 7 , The fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com