Backwashing high-pressure filter station

A high-pressure filter and backwashing technology, which is applied in the direction of filtration circuit, filtration separation, fixed filter element filter, etc., can solve the problems that the whole product cannot operate normally, the whole filter station cannot be used, and the online function cannot be realized. Achieve clean and thorough cleaning effect, unique recoil performance and good recoil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

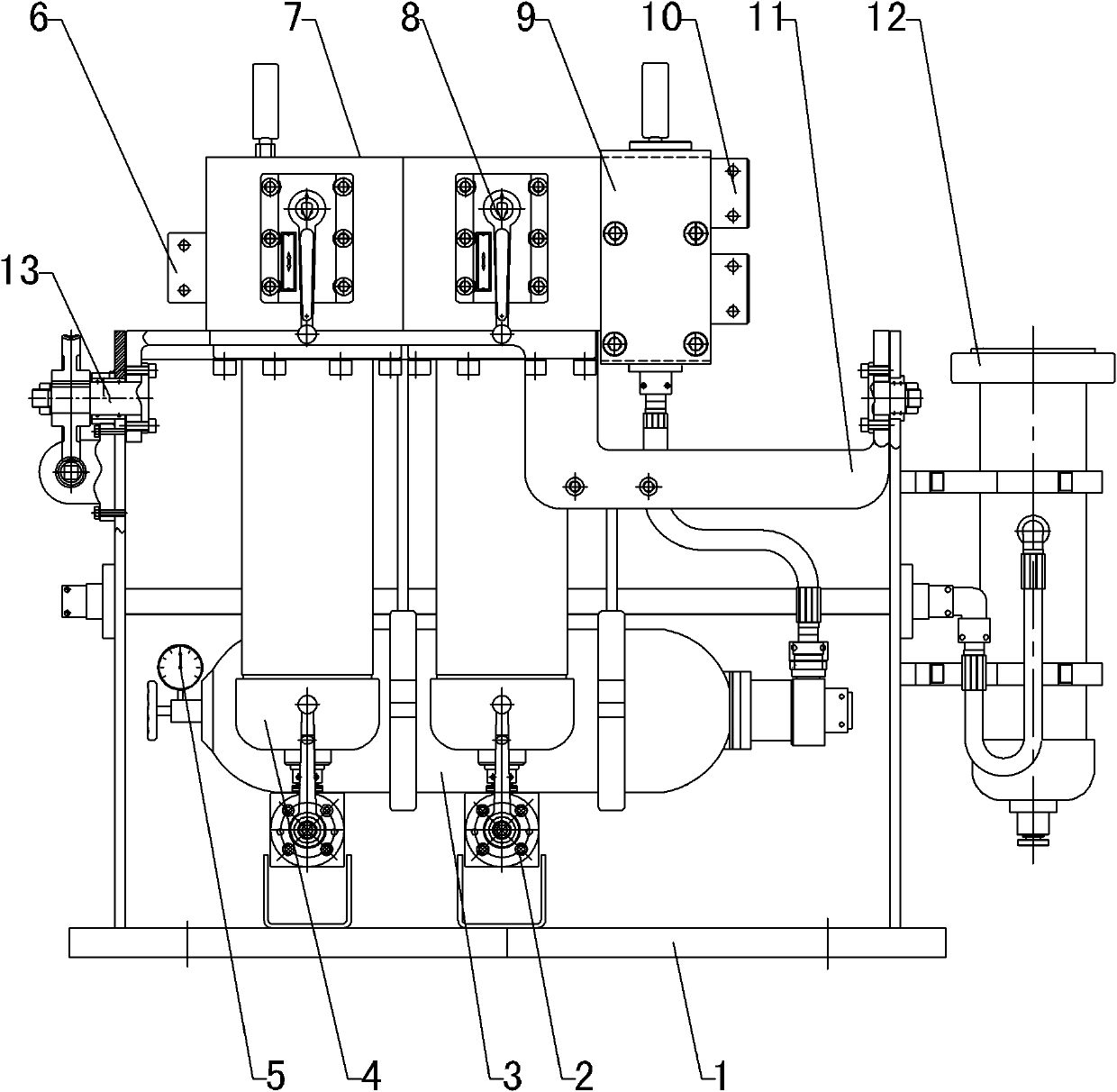

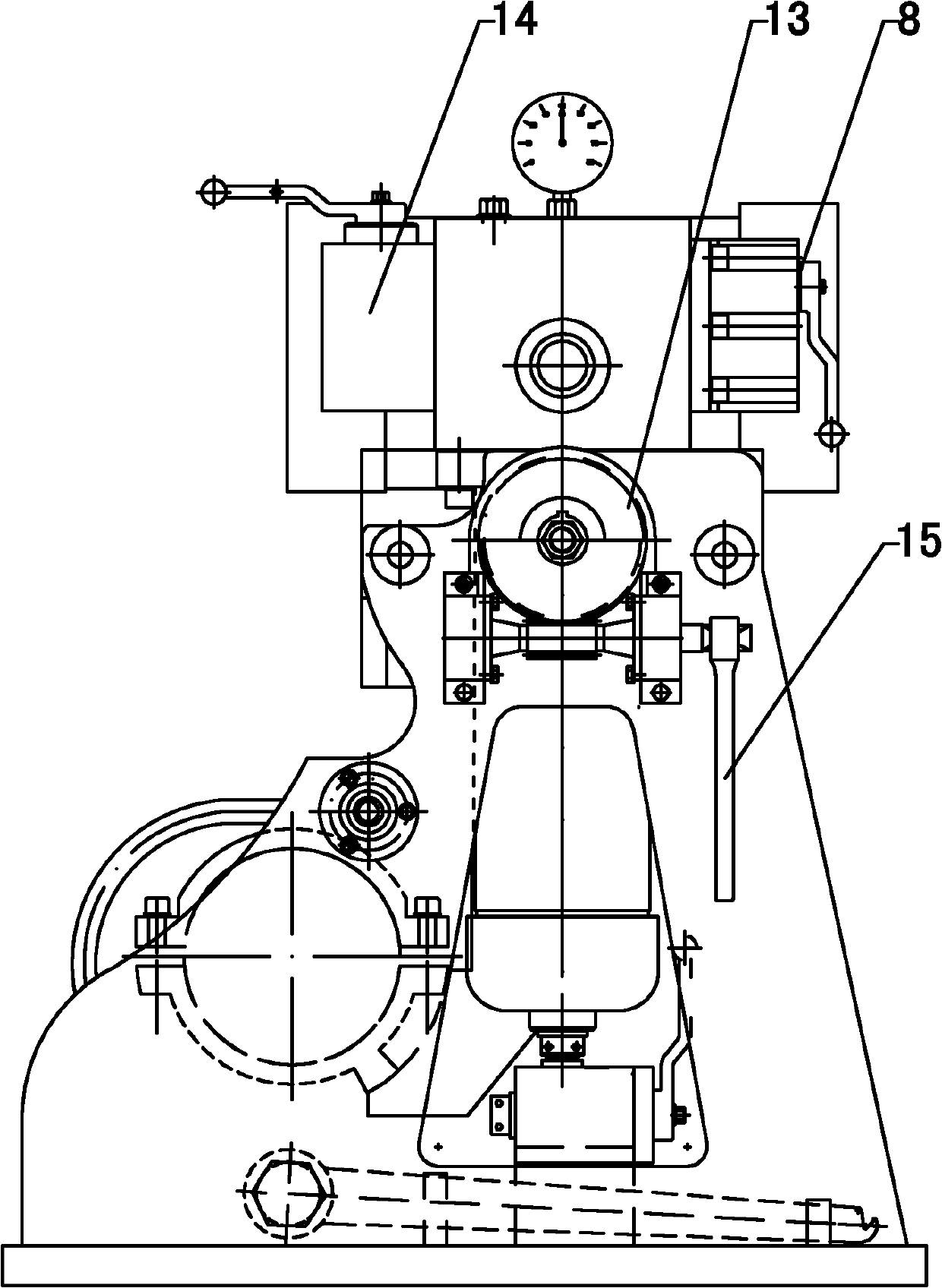

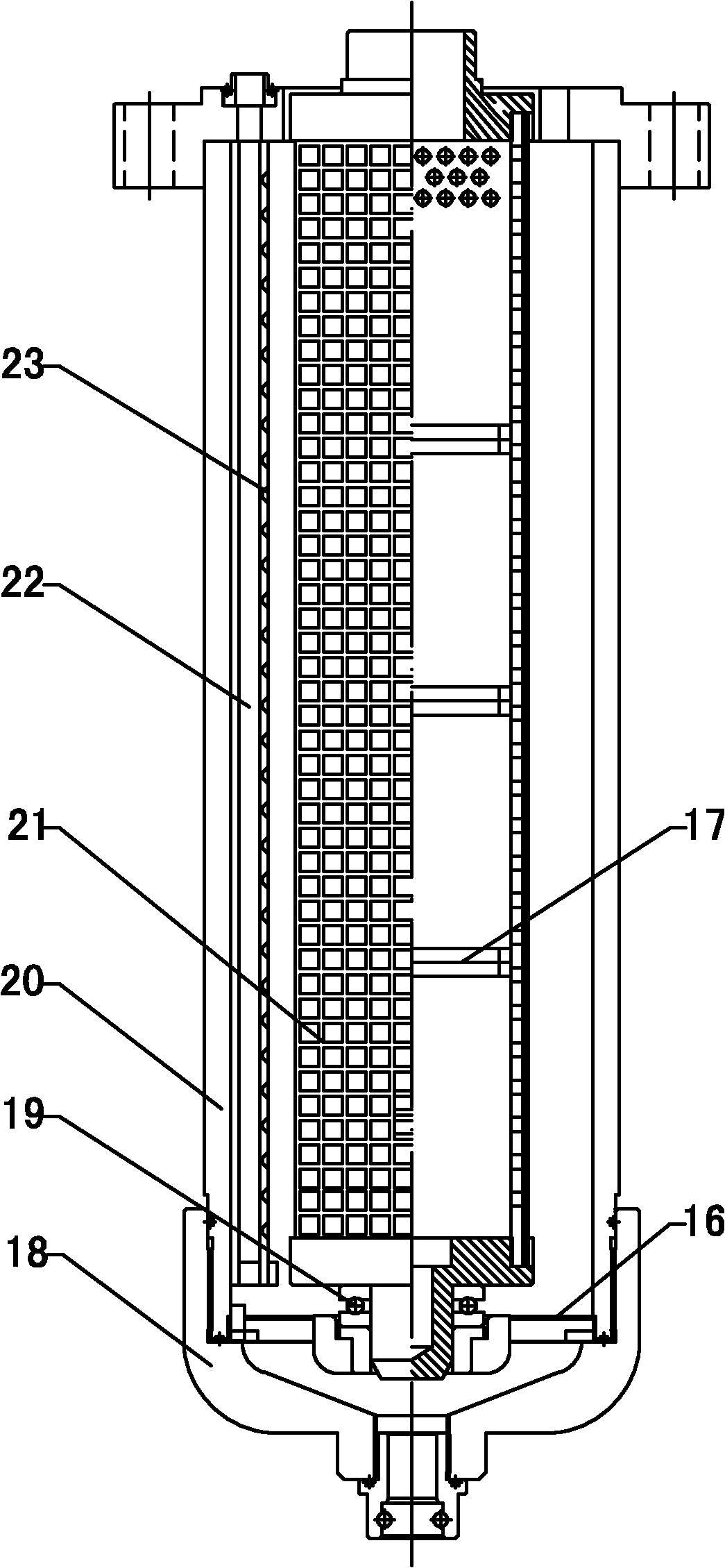

[0022] Refer to attached Figure 1~3 :

[0023] The backwash high-pressure filter station includes machine base 1, sewage valve 2, accumulator 3, high-pressure filter 4, integrated valve seat device 7, rotating machine base 11 and recovery filter 12, and the upper part of machine base 1 is equipped with a rotating machine base 11. A transmission mechanism 13 is installed at the connection between one side of the rotating base 11 and the upper part of the base 1. The transmission mechanism 13 is a worm gear transmission mechanism, and a rotating handle 15 is equipped on the transmission shaft of the transmission mechanism 13. The rotating base 11 passes A plurality of bolts are fixed to install the integrated valve seat device 7. The bottom of the integrated valve seat device 7 is connected to the high pressure filter 4 and the accumulator 3. The high pressure filter 4 and the integrated valve seat device 7 are fastened by M20 high-strength bolts and sealed by a sealing ring. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com