Method for making organic biological flower pots and granules from dewatered sludge

A technology for dewatering sludge and organic organisms, applied in the direction of sewage/sludge fertilizer, organic fertilizer, application, etc., to achieve the effect of reducing fertilization, good social benefits, and reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

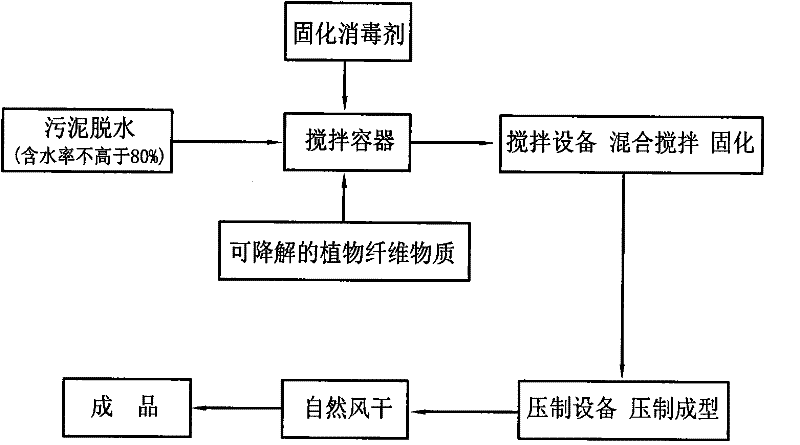

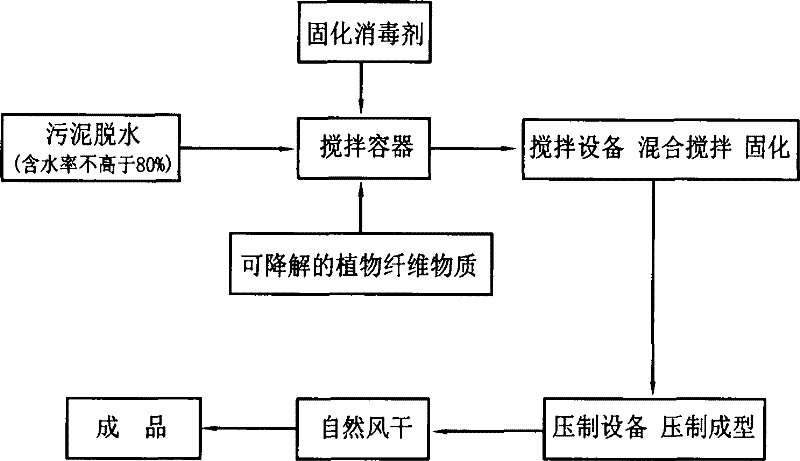

Image

Examples

Embodiment Construction

[0013] Dewater the sludge formed by domestic sewage treatment, so that the moisture content of the dewatered sludge is not higher than 80%, and the dewatered sludge containing the organic components of the maintenance plants and the moisture content is not higher than 80% is placed in the stirring container. Add CaO as curing and disinfectant, add degradable plant fiber material as molding core material, mix and stir with mixing equipment, solidify and disinfect the sludge, and the mixing time is generally 15-15 according to the difference in the moisture content of the sludge. After 30 minutes, it is transported to pressing equipment for pressing and forming, and after forming, it is naturally air-dried for 5 to 7 days (the moisture content is reduced to 40% to 45%) to become a finished product.

[0014] The weight ratio of the dewatered sludge is 90%-93%, the added amount of CaO is 5%-8%, and the added amount of degradable plant fiber is 2%-4%.

[0015] Dewatered sludge cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com