Striking-force test fixture for keyboard lines

A technology for testing fixtures and lines, which is applied in circuit breaker testing, and the measurement of balance force using force. Deformation, avoid wear and measurement center position change, improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

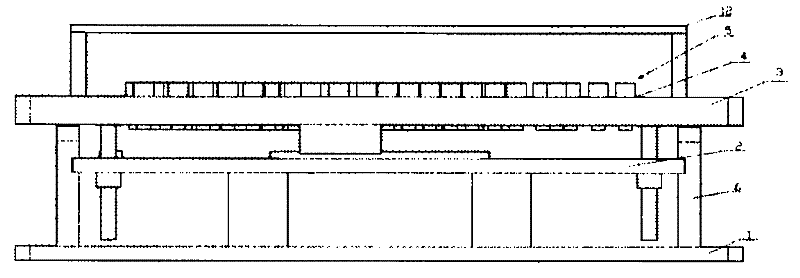

[0023] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

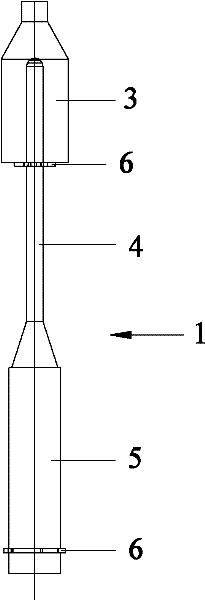

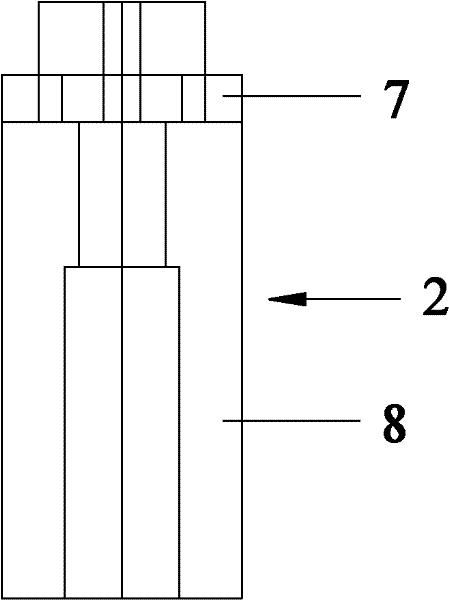

[0024] see figure 2 , 3 As shown, the keyboard circuit knocking force test fixture includes a base 1, a test table 2 horizontally arranged above the base 1 for supporting the keyboard circuit, a test splint 3 positioned above the test table 2 and horizontally arranged, and a test splint 3 set on the test splint 3 A perforation 4 extending vertically, a solenoid valve 5 fixedly inserted in the perforation 4, a power supply for supplying power to the solenoid valve 5, the solenoid valve 5 includes a hollow valve body 7 vertically inserted in the perforation 4, a vertical The magnetic core rod 8 directly inserted in the valve body 7 is connected to the valve body 7 by the power supply. The magnetic core rod 8 includes a thick rod part 9 and a thin rod part 10 distributed sequentially from top to bottom along the length direction of the rod. The pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com