Universal gage for M value of internal spline

An internal spline and M-value technology, applied in the field of internal spline M-value universal inspection tools, can solve the problems of difficult positioning of measuring rods, reduced measurement efficiency, and inconvenient measurement, so as to avoid batch scrapping, convenient operation, and consistent products good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

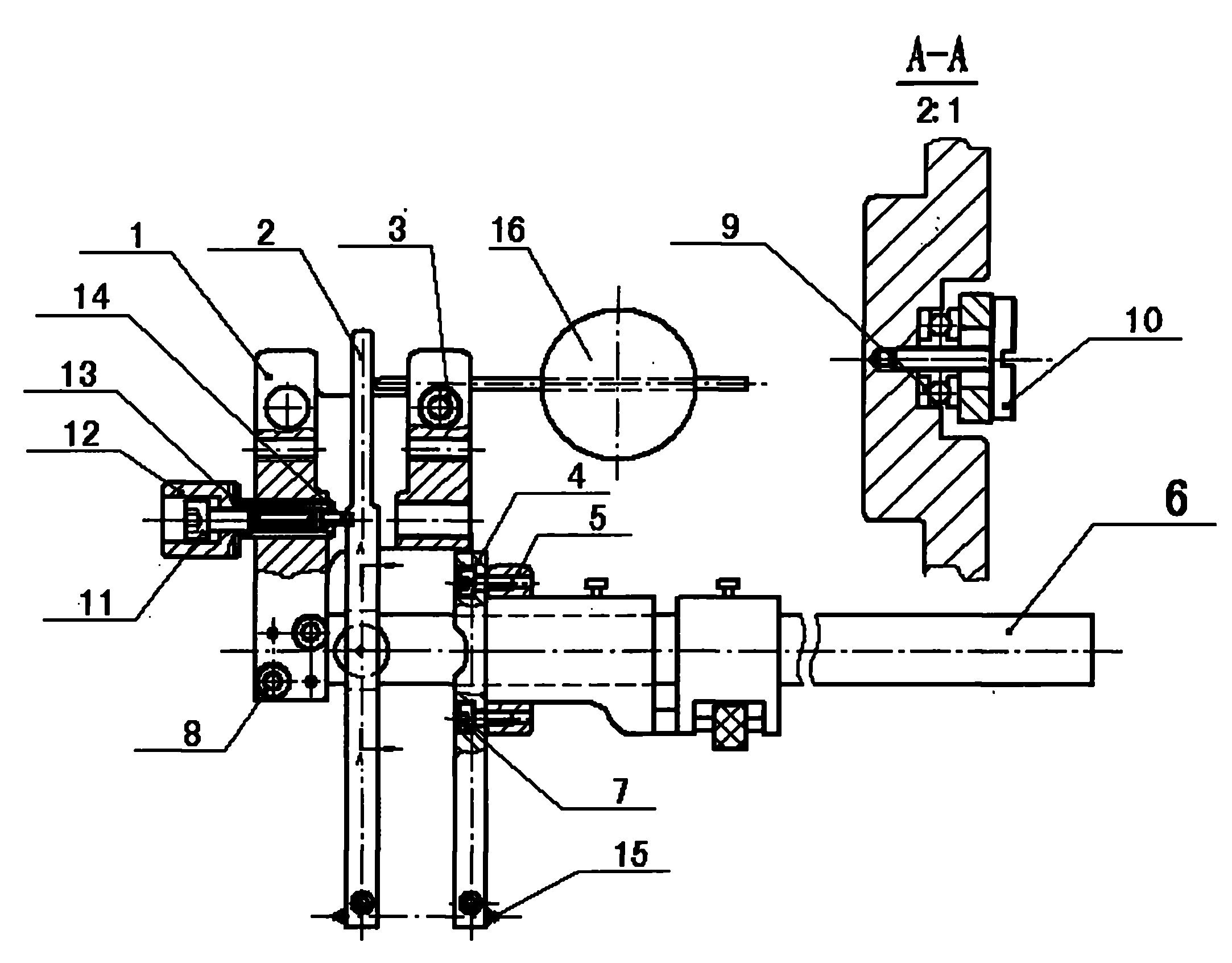

[0017] see figure 1 , the present invention is a kind of stainless steel internal spline M-value universal inspection tool, which consists of a fixed body 1, a swing rod 2, a bottom plate 3, a fixed rod 4, a ferrule 5, a scale rod 6, a hexagon socket head screw 7, an inner Composed of hexagonal cylindrical head screw 8, miniature plane bearing 9, locking screw 10, inner hexagonal cylindrical head screw 11, self-made screw 12, spring 13, ejector rod 14, measuring head 15, dial indicator 16;

[0018] One end of the lower part of the fixed body 1 is fixedly connected with the scale rod 6 by a hexagonal cylindrical head screw 8; the middle part of the fixed body 1 is screwed with a self-made screw 12, and the self-made screw 12 is pressed by a hexagonal cylindrical head screw 11 to press the spring 13 and the ejector rod 14;

[0019] One end of the ejector rod 14 is pressed against the swing rod 2; the swing rod 2 is connected with the scale rod 6 through the locking screw 10 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com