Bottom independent evacuation safety passage structure for single-hole double-track magnetic levitation tunnel

A safety channel, single-hole double-line technology, applied in safety devices, mining equipment, earthwork drilling and mining, etc., can solve problems such as poor evacuation capacity, inability to set up evacuation space, difficulty in ventilation and rescue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] based on the following Figure 2 ~ Figure 4 , specify the preferred embodiment of the present invention:

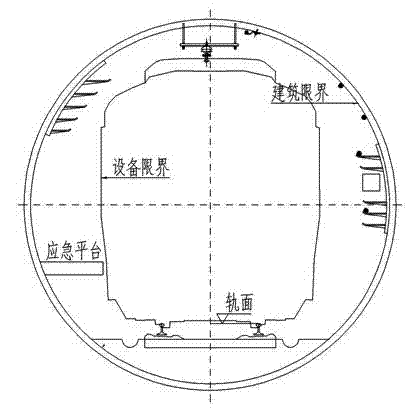

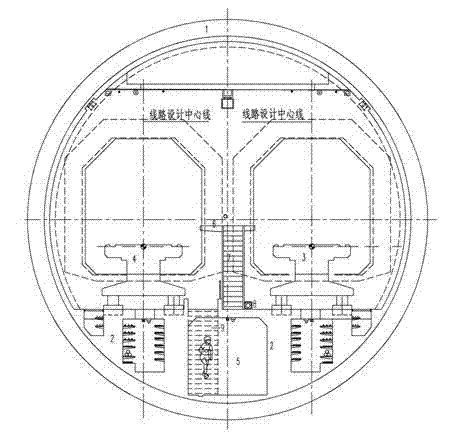

[0022] Such as figure 2 with image 3 As shown, it is a cross-sectional view of the bottom independent evacuation safety passage structure for a single-hole double-line maglev tunnel. The bottom independent evacuation safety passage structure is arranged in the tunnel segment structure 1, which includes a safety passage 5 and an escape platform 6;

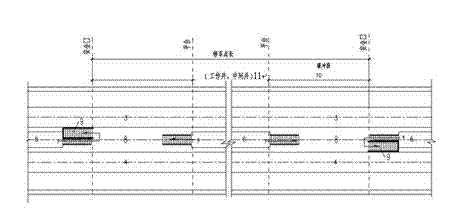

[0023] The safety channel 5 is located between the upward track 3 and the upward track 4, and is arranged under the rail platform 2. The safety channel 5 runs through the working wells 11 at both ends longitudinally (such as Figure 4 As shown), it is connected with the lower layer of the working shaft, and the air is blown by positive pressure from the fan room of the lower layer of the working shaft to form a smoke-proof passage.

[0024] Cable trays, equipment boxes, and water supply and drainage pipes are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com