Press roll for filament winding head

A technology of filament winding and pressing roller, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. It can solve the problem of end breakage and stripping, not the winding speed, and the bottom layer of the new silk cake To solve problems such as poor winding, achieve the effect of high wire loop density, increase winding speed, and firm and stable placement position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

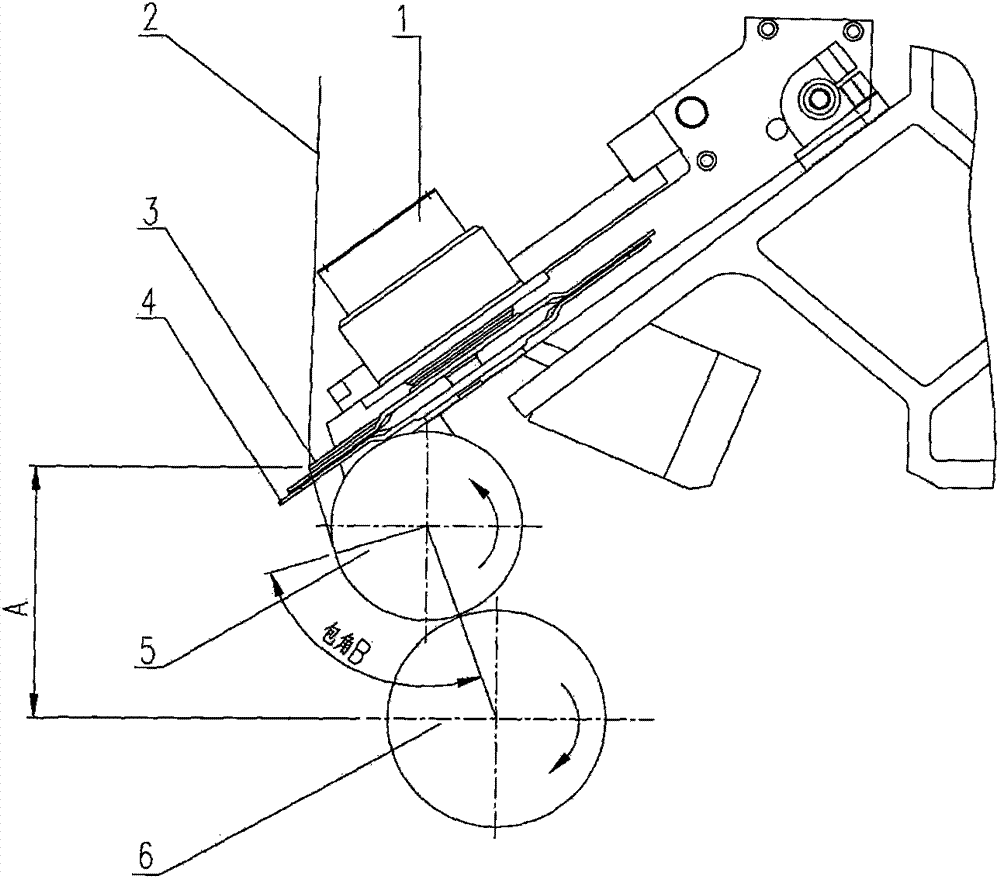

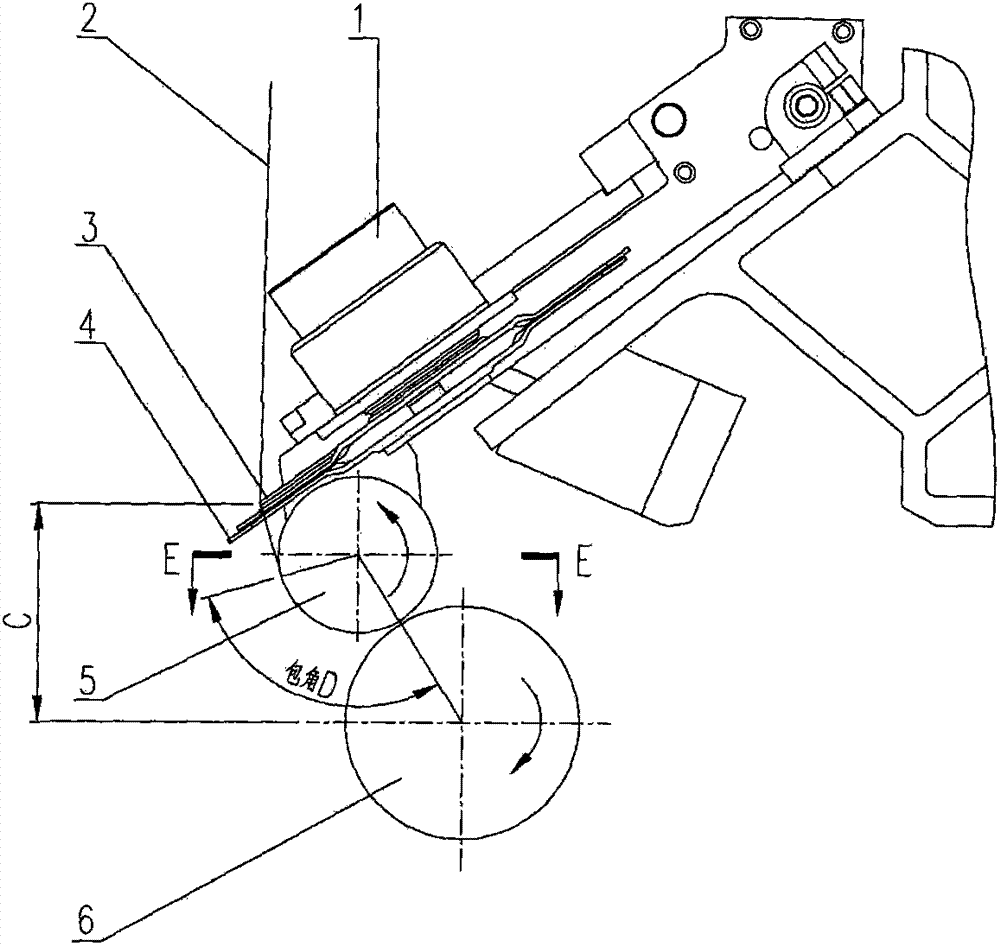

[0018] In the figure, the tow 2 reciprocates alternately along the forming plate 3 through the fork 4 driven by the gear box 1, and the bobbin is installed on the chuck shaft 6, and the chemical fiber filament is wound into a cylindrical shape on the bobbin of the winding head. rolls.

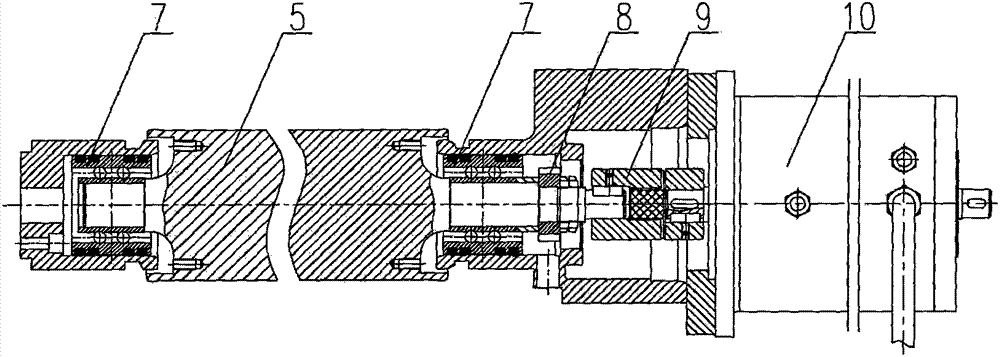

[0019] exist image 3 Among them, the pressure roller 5 is supported by a bearing 7, and the motor 10 is connected with one end of the pressure roller 5 through a coupling 9. Because the moment of inertia of the roller body changes from hollow to solid, the pressure roller is now driven by an asynchronous high-speed motor, changing from passive to active. After the automatic switching of the winding head, the speed of the pressure roller 5 will not be affected by the detachment from the chuck shaft, which will have an ideal contact pressure for the winding of the bottom silk of the new silk cake, and the silk during the winding cycle The circles are closely arranged, and the degree of closene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com