Box structure for filter

A box structure and filter technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, separation methods, etc., can solve the problem of polluting the downstream space of the filter, and achieve the effect of saving production consumables and improving productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

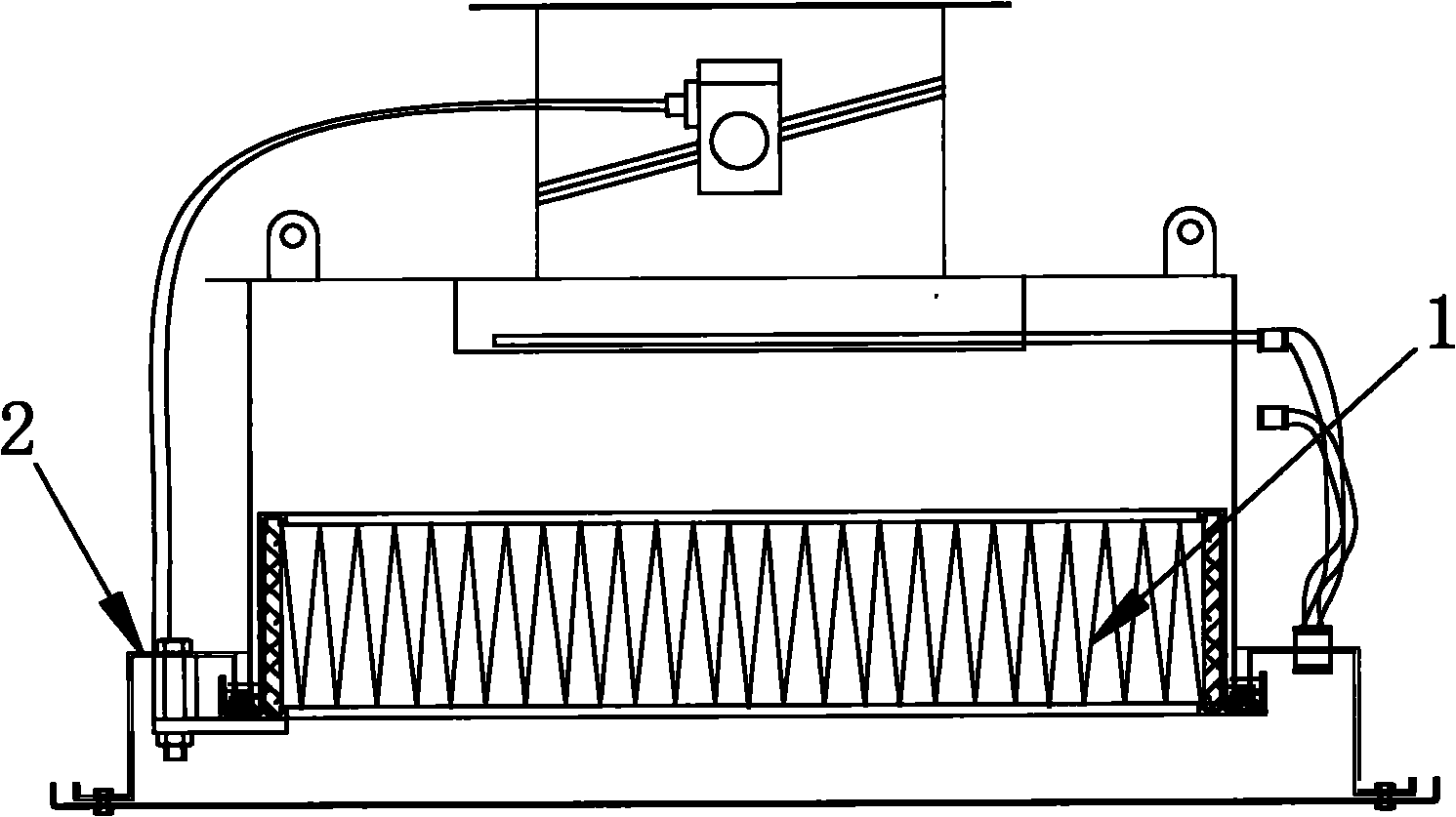

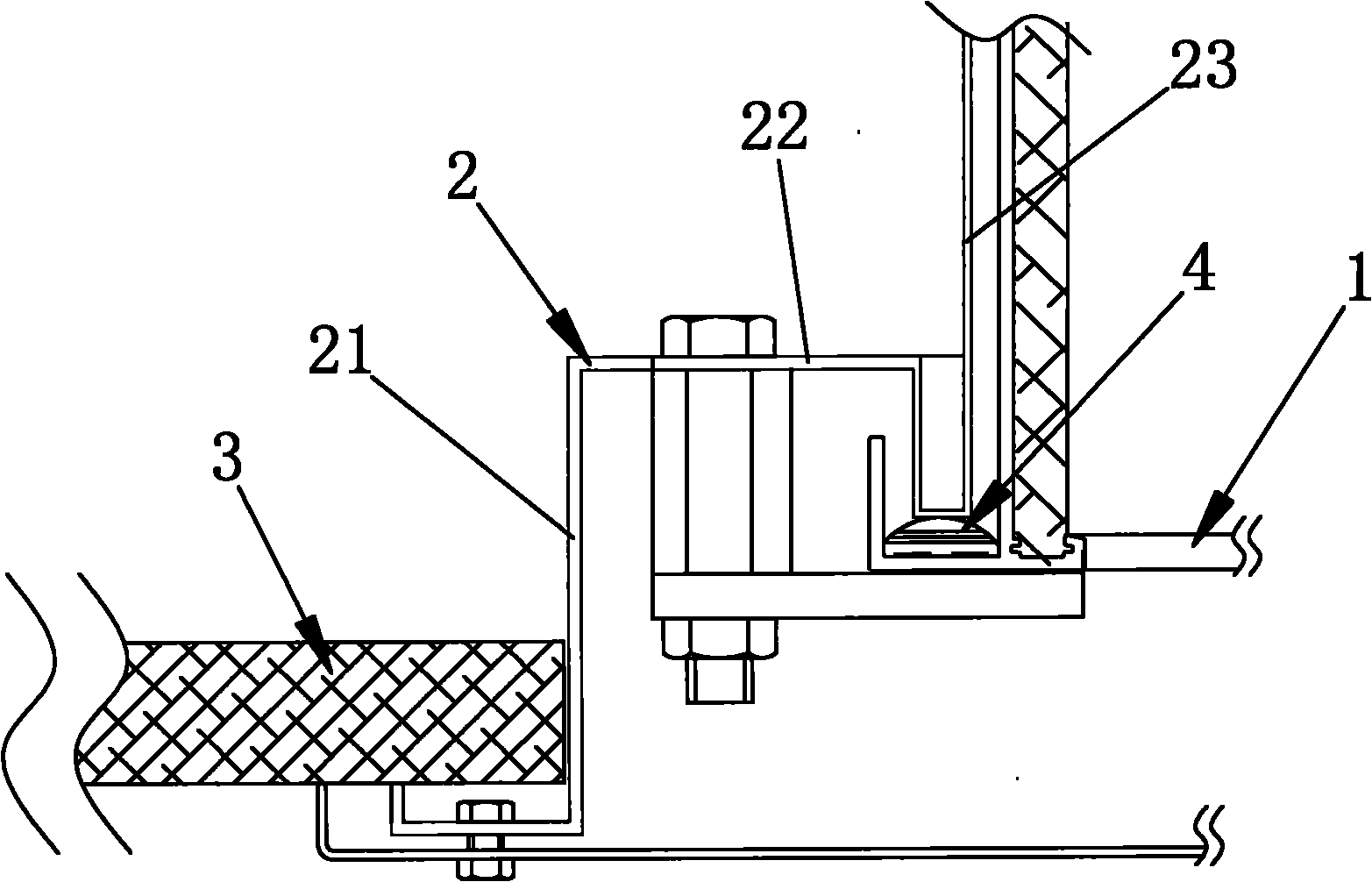

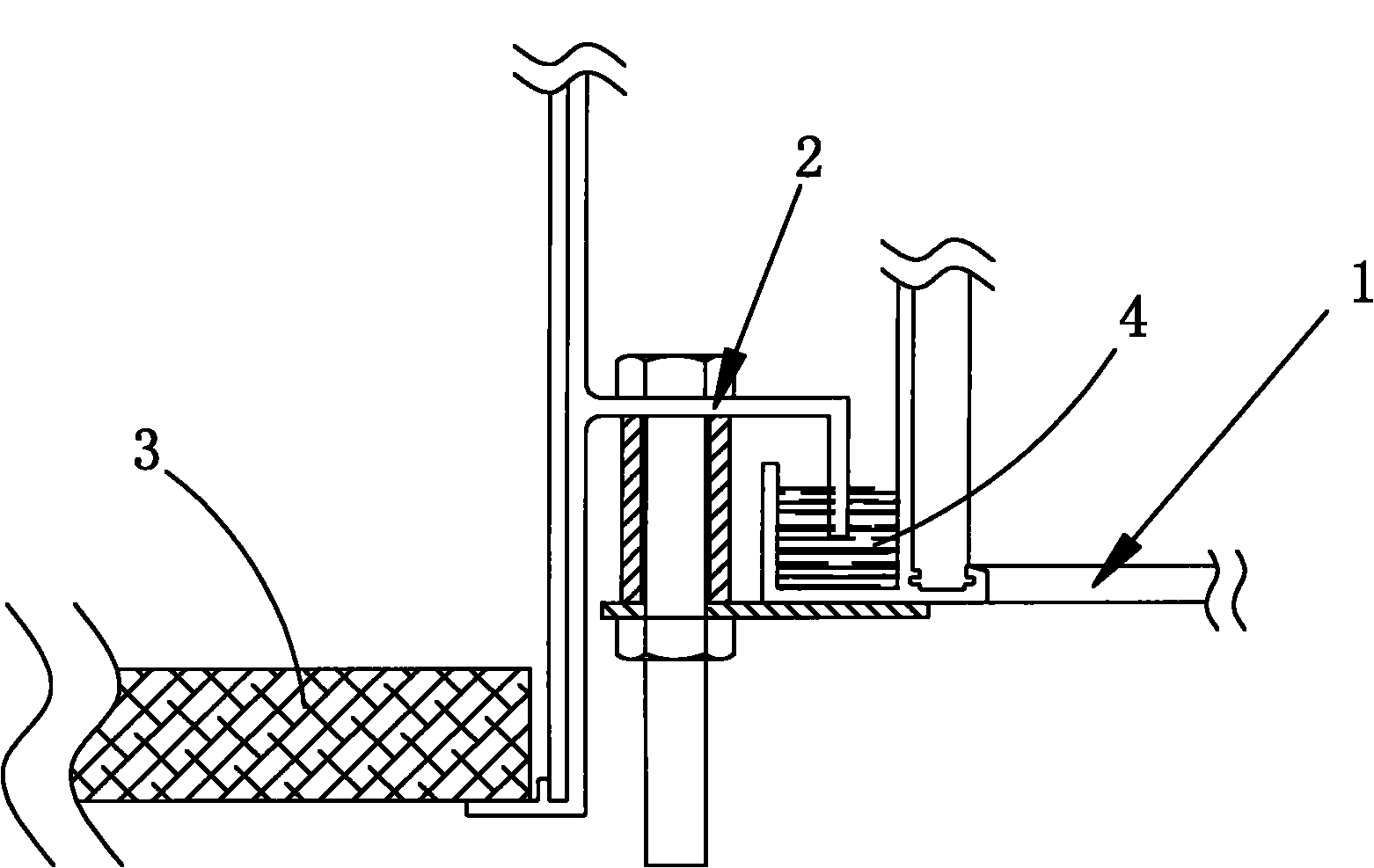

[0010] Embodiment: A box structure of a filter, including a box partition 2, the filter is sealed and positioned on the box partition 2 through a sealing material 4, based on the use direction, the back of the filter 1 faces the clean room, the front of the filter 1 faces the vent, and the box partition 2 is composed of a wall partition 21, a horizontal partition 22 and a filter partition 23, and the wall partition 21 is fixedly connected to the clean room wall Body 3, the filter 1 is sealed and positioned on the filter partition 23, the wall partition 21 and the filter partition 23 are transitionally connected by a horizontal partition 22, and the box partition 2 is integrally bent The filter partition 23 is a double-layer partition formed by bending the side of the horizontal partition 22 close to the filter toward the back of the filter 1, then bending away from the wall, and then bending toward the front of the filter 1. plate, the filter partition 23 blocks the filter and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com