Biodegradable filling for restoration of alveolar bone

A bone repair and decomposing technology, applied in medical science, dentistry, dental preparations, etc., can solve problems such as skewed teeth, insufficient alveolar bone height or width, and inability to grow enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Preparation of cross-linked collagen fibers

[0047] Add atelocollagen with a concentration of 3.0±0.5mg / mL to 0.2M phosphate buffer solution, adjust the pH value to 7.0±0.2, keep stirring for 4 hours, then add glutaraldehyde with a final concentration of 0.003%. Or use 1-ethyl-3-(dimethylaminopropyl) carbodiimide (EDC) with a final concentration of 0.004% and N-hydroxysuccinimide (NHS) with a final concentration of 0.0016% as a cross-link agent, and adjust the pH value to 5.5±0.2, control the temperature at 35±5°C and keep stirring for 16 hours to carry out the chemical crosslinking reaction.

[0048] After the chemical cross-linking reaction, the cross-linked collagen fibers were miniaturized with a homogenizer, which was homogenized at 10000±200rpm for 10±2 minutes, and then centrifuged at a centrifugal force of 14000G for 1 hour to collect the cross-linked collagen fibers The concentration of the precipitate, resulting cross-linked collagen fibers generally ranges ...

Embodiment 1

[0056] Using biphasic phosphate as support particles, tricalcium phosphate (β-TCP) with a particle size of 0.5 to 2.0 mm and hydroxyl apatite (HAP) with a particle size of 0.075 to 0.150 mm are used to 60%: 40% weight ratio mixed.

[0057] Take the 30±0.2 mg / mL cross-linked collagen fiber slurry prepared above, and mix the above HAP / β-TCP complex into the cross-linked collagen fiber slurry, wherein the cross-linked collagen fiber slurry: HAP The / β-TCP complex was mixed in a weight ratio of 30%:70%.

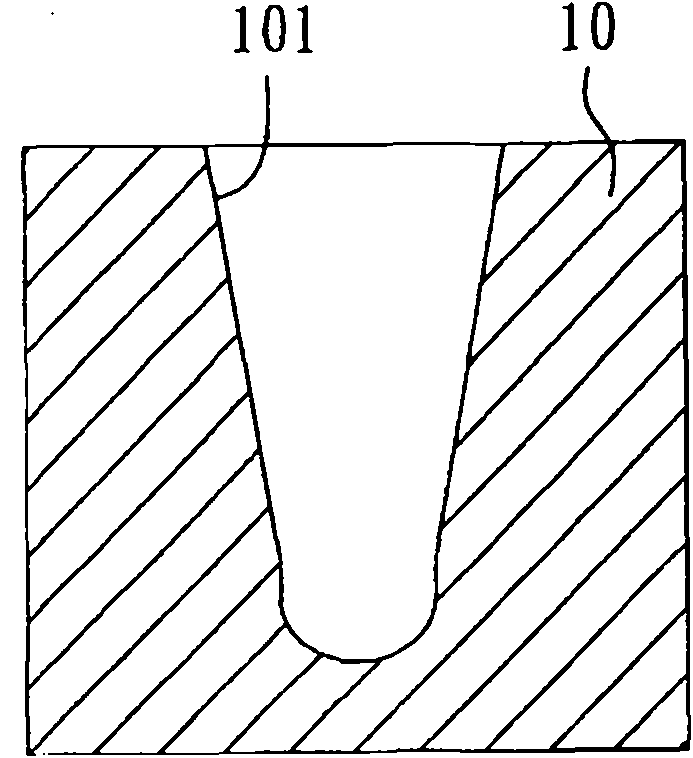

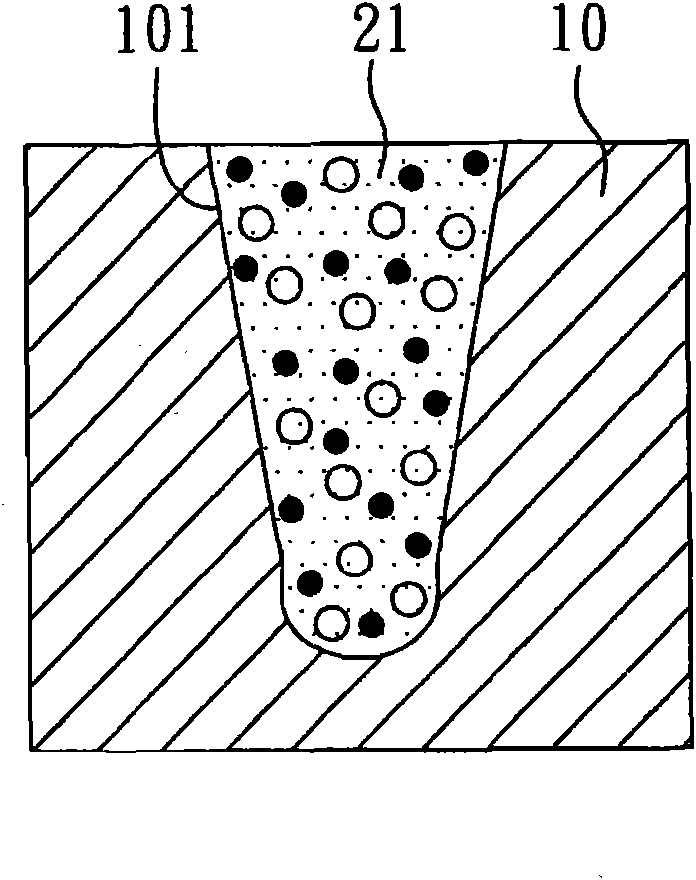

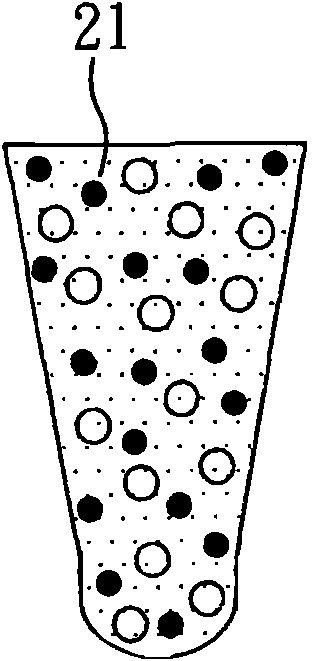

[0058] The molding method of the biodegradable filling material used for alveolar bone repair in this embodiment can be referred to Figures 1A to 1C . First, if Figure 1A As shown, a forming mold 10 is prepared, which has a forming groove 101. The inner diameter of the forming groove 101 gradually decreases from the opening to the inside like a trumpet, and its bottom is arc-shaped, so that the subsequent fillings are formed as a whole. Domed cone. The diameter of the openi...

Embodiment 4

[0068] HAP / β-TCP complex and bioactive glass were used as support particles, in which tricalcium phosphate (β-TCP) / hydroxyapatite (HAP) with particle size between 0.5 and 1.0 mm and particle size between Bioactive glass at 150 to 600 μm.

[0069]Take the 30±0.2 mg / mL cross-linked collagen fiber slurry prepared above, mix HAP / β-TCP complex and bioactive glass into the cross-linked collagen fiber slurry, wherein the cross-linked collagen fiber Slurry:HAP / β-TCP complex:bioactive glass was mixed in a weight ratio of 30%:35%:35%.

[0070] The molding method of the biodegradable filling material used for alveolar bone repair in this embodiment can be referred to Figures 6A to 6G . First, if Figure 6A As shown, a forming mold 12 is prepared, which has a forming groove 112. The inner diameter of the forming groove 112 is approximately the same from the opening to the inside, but the inner diameter gradually decreases until the bottom, so that the subsequent fillings are formed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com