Spherical crop screening device

A screening device and crop technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of low efficiency, high labor consumption, lack of unified standards, etc., and achieve the effect of accurate structure, reasonable layout and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

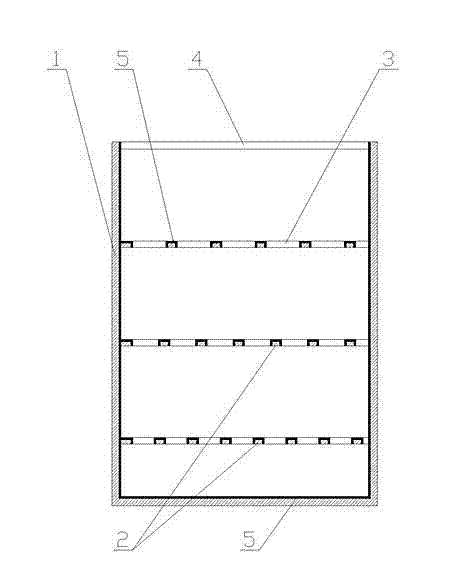

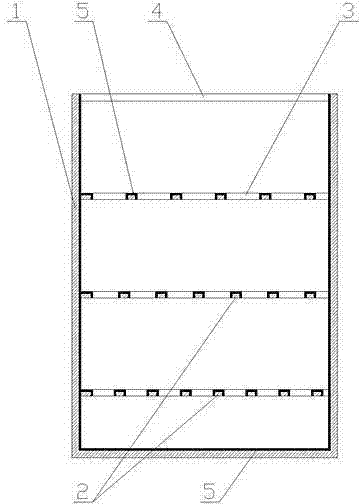

[0009] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. like figure 1 Shown: a spherical crop screening device, which includes a shell 1 as a basis, at least two partitions 2 are arranged inside the shell 1, and the inner cavity of the shell 1 is divided into at least three layers, in each There are a plurality of screening holes 3 on the partition plate 2, and the closer the partition plate 2 at the bottom of the shell 1 is, the smaller the diameter of the screening hole 3 is. One side of the body 1 is a movable door; in order to prevent damage caused by the collision between the crops and the inner wall of the shell 1 or the partition 2 during the screening process, the inner surface of the shell 1 and the outer surface of the partition 2 are also provided with flexible Layer 5.

[0010] The working process of the spherical crop screening device according to the embodiment of the present invention is as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com