Method for stabilizing parameters of annular shred dryer through parallel translation of water ratio

A technology of parallel movement and moisture content, applied in the field of tobacco processing industry, can solve the problems of changes in the quality of cigarette products and the change of moisture content requirements at the drying outlet of leaf silk, so as to eliminate the changes of operating parameters and ensure the effect of processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

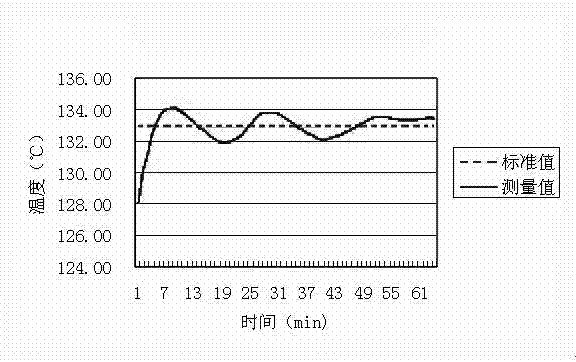

[0015] Embodiment 1: Carry out the silk making experiment by adopting the original process standard, and the experimental sample is compiled into 1# sample.

Embodiment 2

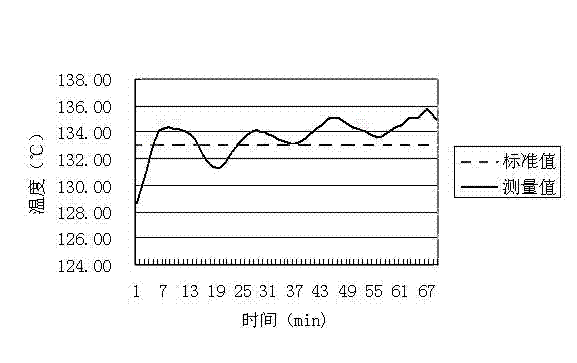

[0016] Embodiment 2: The standard adjusted by the traditional method is used to carry out the silk making experiment, and the experimental samples are compiled into 2# samples.

Embodiment 3

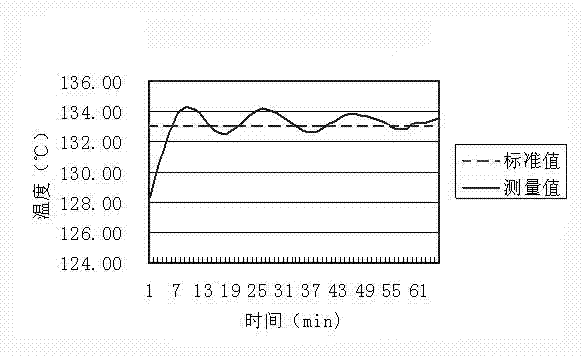

[0017] Embodiment 3: Carry out the silk-making experiment with the standard adjusted by the moisture content parallel moving method, and use the ring-shaped silk drying machine to dry the leaf silk; The moisture content of the silk is adjusted precisely so that it is adjusted in the same direction as the moisture content at the outlet of the drying process. The moisture content moves in parallel before and after drying the silk, so that the dehydration amount of the silk during the drying process is consistent. The experimental samples are compiled into 3# samples.

[0018] (2) Experimental results

[0019] The standard production samples of the original process are coded as 1# samples; the samples produced according to the traditional method to adjust the standard are coded as 2# samples, and the samples produced by the water content parallel moving method are coded as 3# samples. See Table 1 for the adjustment of the production process parameters and quality index setting v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com