Fixing assembly

A technology for fixing components and fixing parts, which is applied to electrical components, digital data processing components, electrical equipment structural components, etc., can solve the problems of complex structure of fixed components and high cost of elastic parts, achieve simple structure and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

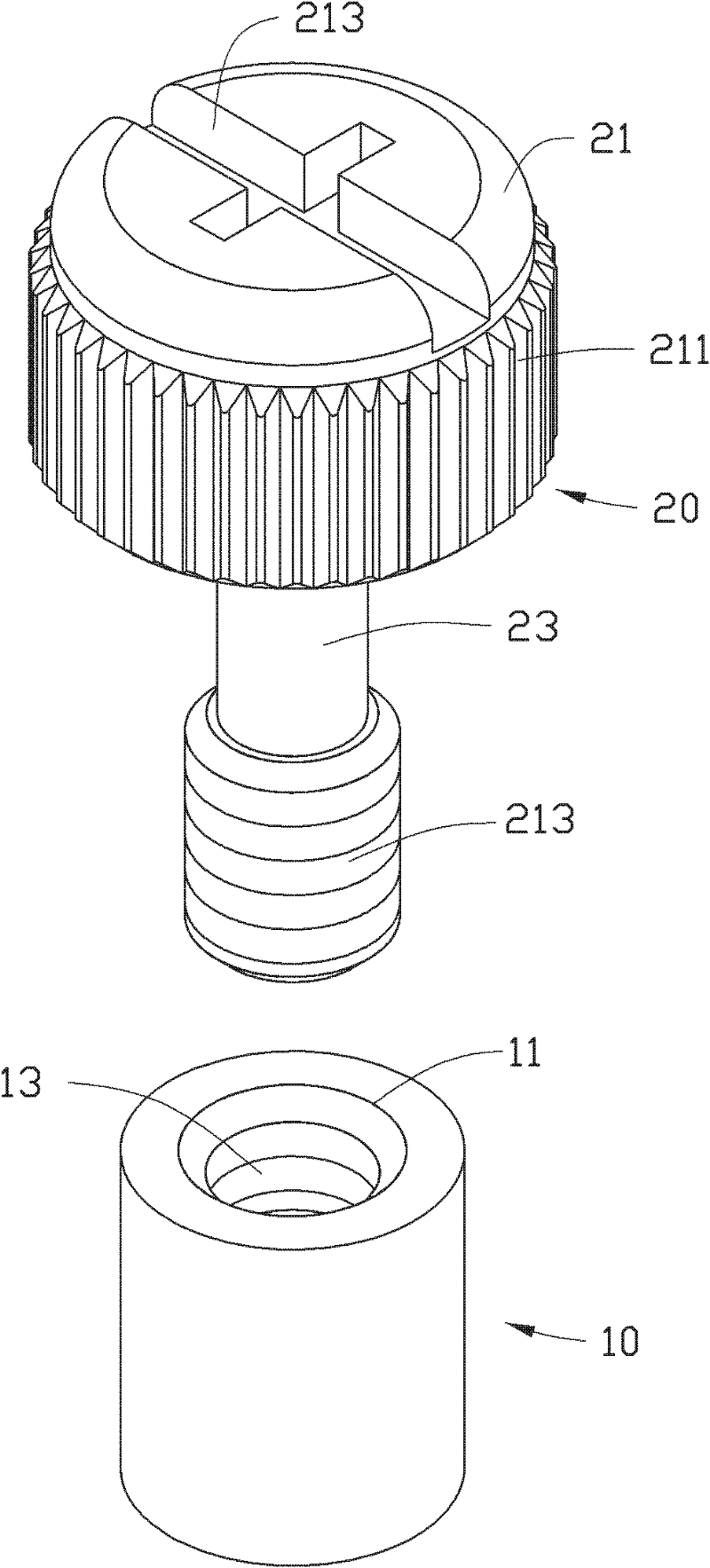

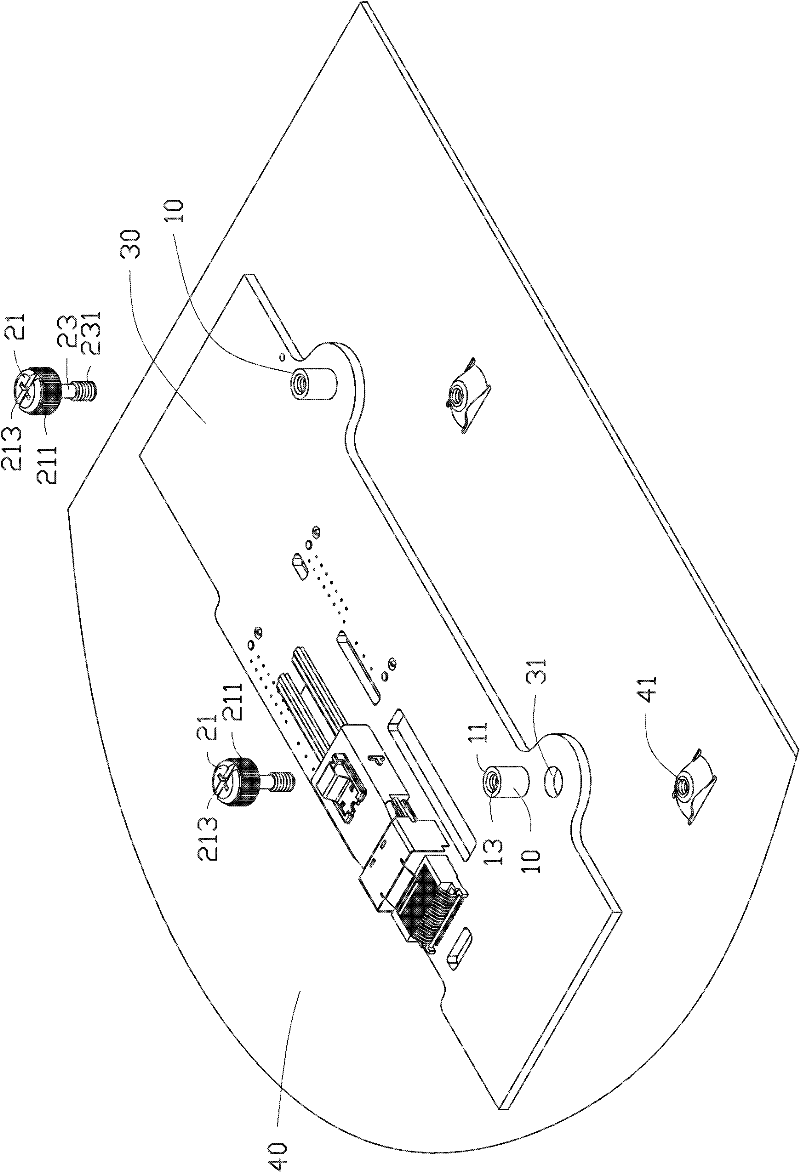

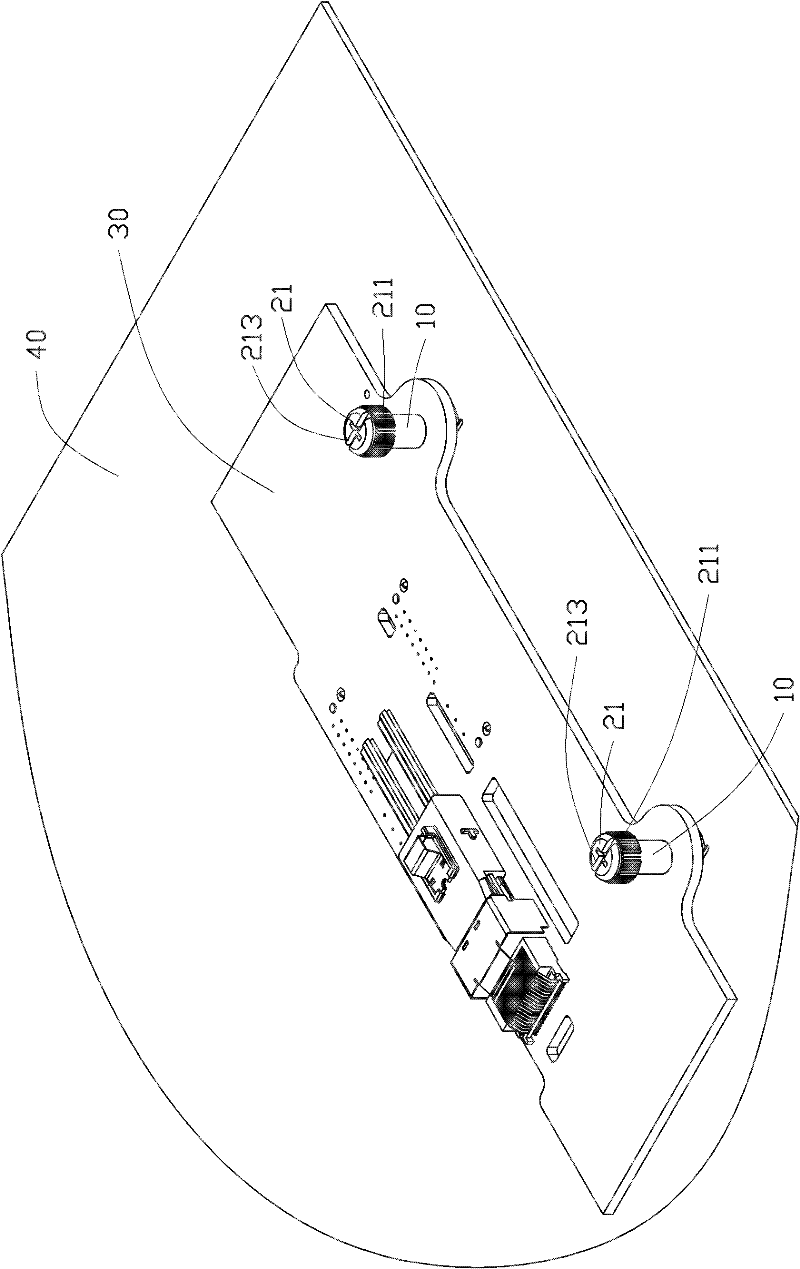

[0018] see figure 1 , A preferred embodiment of the fixing assembly of the present invention includes a first fixing part 10 and a second fixing part 20 cooperating with the first fixing part 10 .

[0019] A positioning hole 11 with an internal thread 13 is defined in the middle of the first fixing member 10 . In a preferred embodiment, the first fixing member 10 and the positioning hole 11 are approximately cylindrical in shape.

[0020] The second fixing member 20 includes a mounting portion 21 and a fixing column 23 connected to the mounting portion 21 . A plurality of threads 211 are defined around the mounting portion 21 , and a driving slot 213 for driving the second fixing member 20 to rotate is defined at the top of the mounting portion 21 . In a preferred embodiment, the threads 211 are vertically arranged at intervals, and the driving groove 213 is roughly in the shape of a "cross". The fixing post 23 has a fixing portion 231 having threads. The fixing portion 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com