Motor vehicle pneumatic tires

A technology for pneumatic tires and vehicles, which is applied to vehicle parts, tire parts, tire treads/tread patterns, etc., and can solve the problems of reduced effect of fine cuts on the grip edge, deterioration of floating characteristics, and obstruction of water discharge, etc. Achieve the effects of reducing loss, enhancing the grip effect, and increasing the length of the grip edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

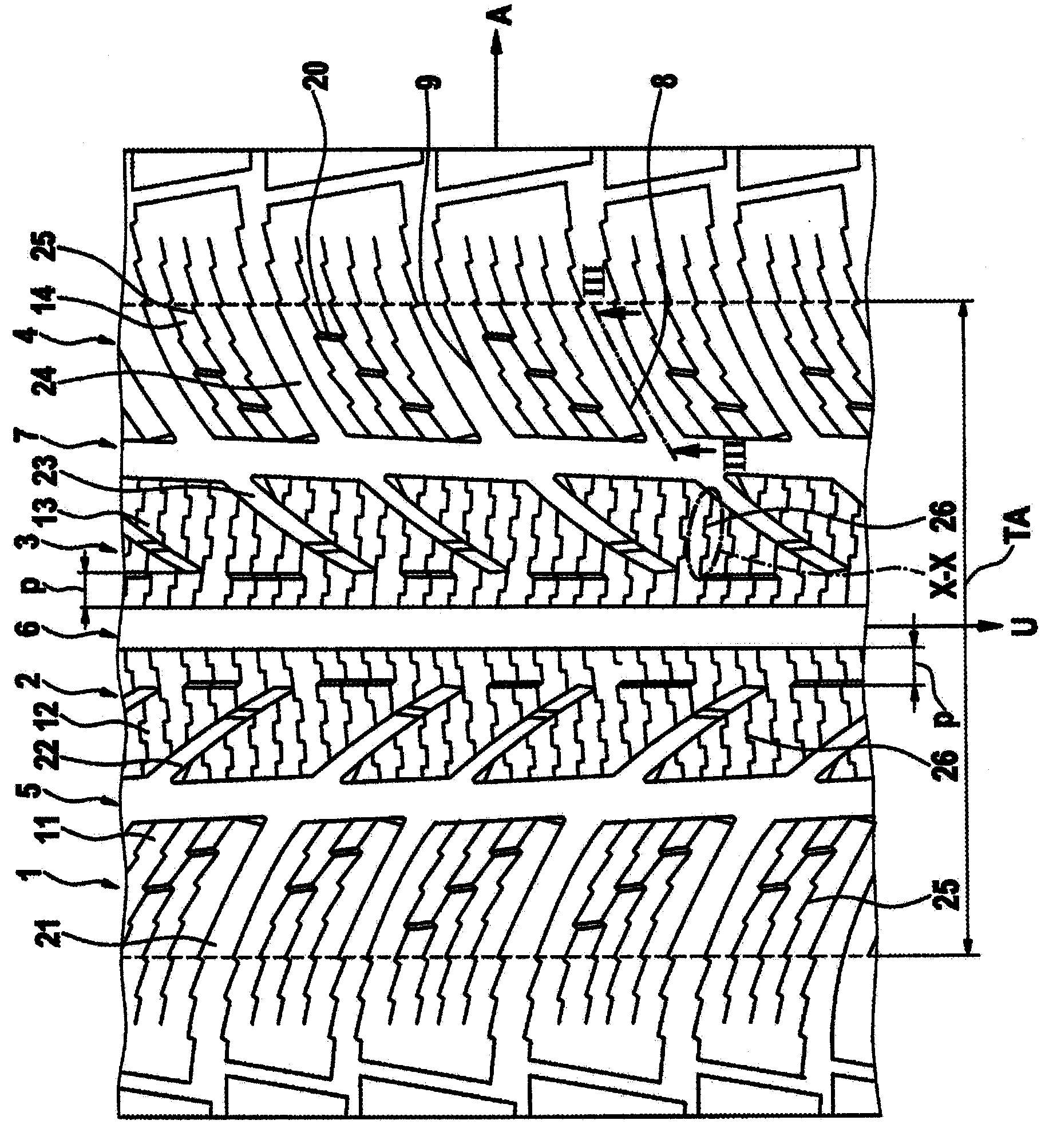

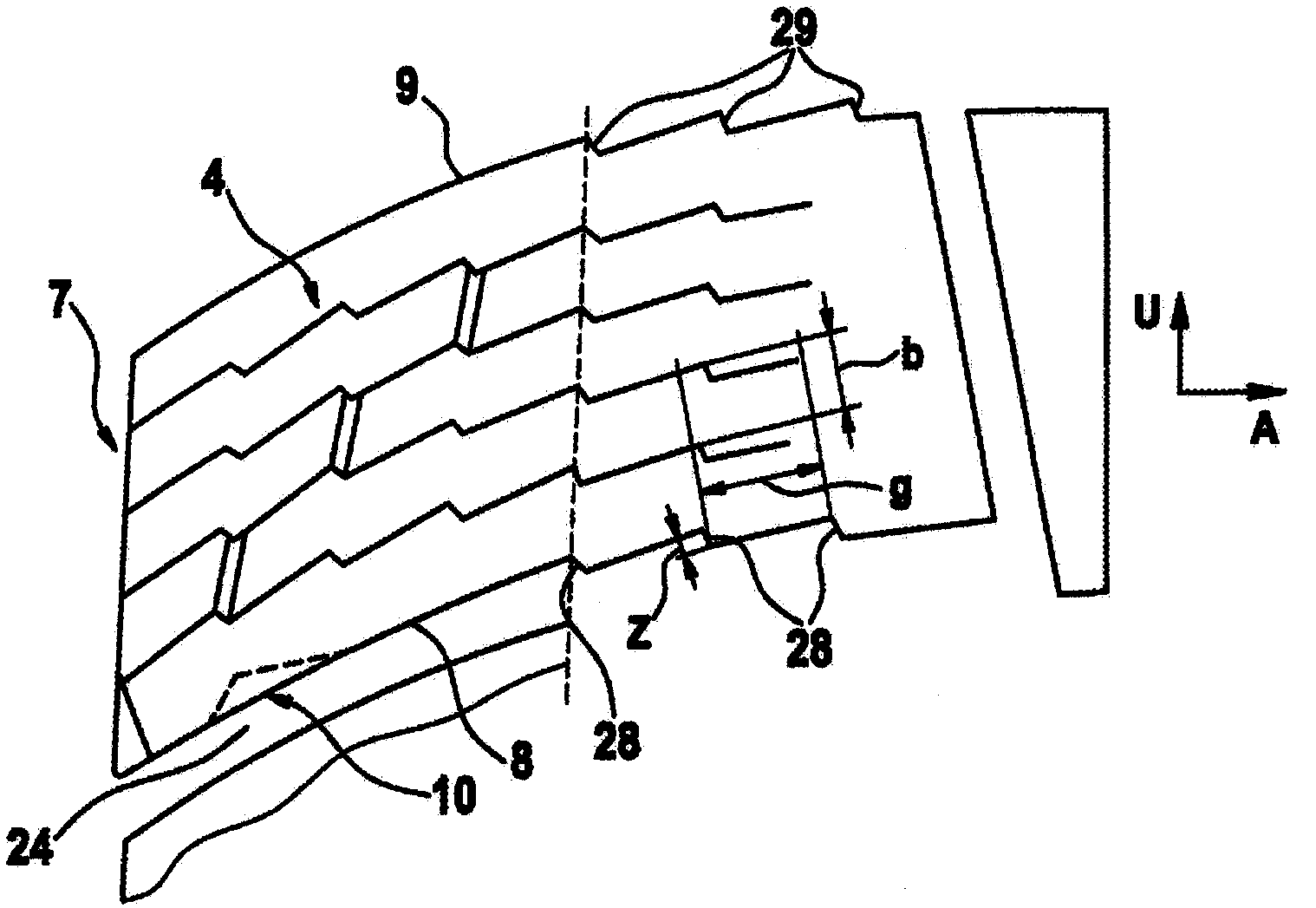

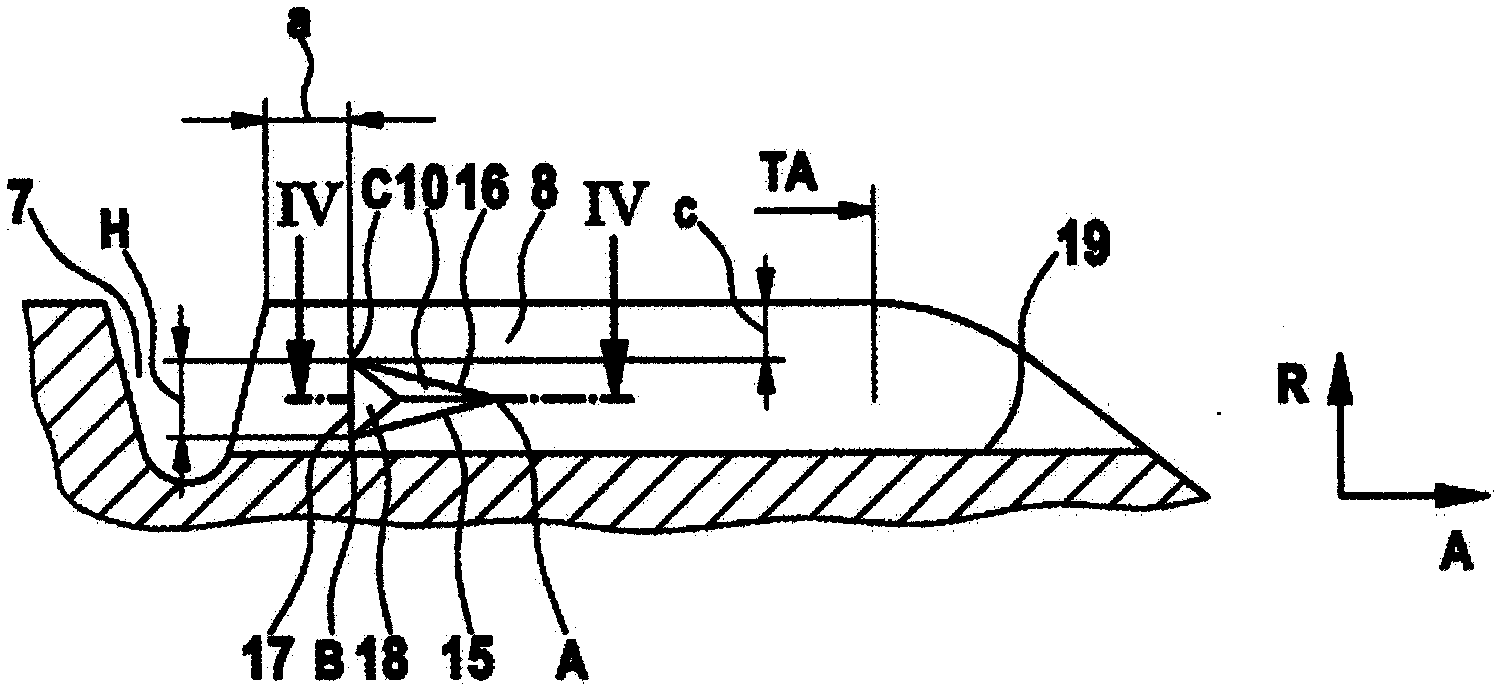

[0064] figure 1 A rotationally bound tread profile of a vehicle pneumatic tire for winter-suitable passenger vehicle tires is shown. This is done in a known manner by (in figure 1 A shoulder profile block row 1 , a profile rib 2 , a profile rib 3 and a shoulder profile block row 4 arranged axially adjacent to each other from left to right in the illustrated embodiment form . The shoulder profile block row 1 is arranged in such a manner that it extends along the circumferential direction U of the vehicle pneumatic tire on the circumference of the vehicle pneumatic tire, is arranged in such a manner that it is successively dispersed on the circumference, and passes through one transverse groove respectively 21 and a plurality of profile block elements 11 arranged in a manner separate from each other are formed in a known manner. The shoulder profile block rows 4 are arranged in such a manner as to extend in the circumferential direction U on the circumference of the vehicle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com