Preparation method of ferrocenecarboxylic acid

A technology of ferrocene formic acid and acetyl ferrocene, applied in chemical instruments and methods, metallocene, organic chemistry, etc., can solve the problems of many by-products, low total yield, and high requirements for experimental equipment, and achieves reaction consumption. Short, easy-to-control, inexpensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In the first step, add 60 ml of deionized water and 10 g of sodium hydroxide to the reactor and stir to dissolve it to form a sodium hydroxide solution; cool the reactor to 0-5°C in an ice-water bath, and add 2 ml of PEG-400 under stirring (Polyethylene glycol) and 16.8 gram iodine-potassium iodides, add the acetyl ferrocene powder that total amount is 2.3 grams then in 40 minutes, each addition is equal, then fully stir 1h;

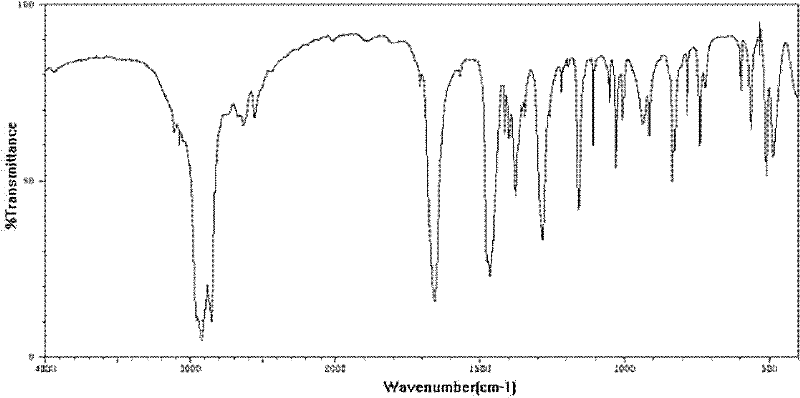

[0023] In the second step, the solution obtained in the first step is extracted and washed twice with dichloromethane, and the water phase is adjusted to PH=2 to 3 with strong acid, and a yellow precipitate is precipitated, filtered after cooling, washed twice with water, and the solid obtained by filtering is di Ferrocene formic acid, the calculated yield by weighing is 85.6%. see figure 1 Shown is the infrared spectrogram of embodiment 1 gained solid product, can find out that institute's product is ferrocenecarboxylic acid by spectrogram.

Embodiment 2

[0025] In the first step, 60 ml of deionized water and 10 g of sodium hydroxide were added to the reactor and stirred to dissolve to form a sodium hydroxide solution; the reactor was cooled to 10°C with an ice-water bath, and 2 ml of PEG-400 and 16.8 gram of iodine-potassium iodide, in 40 minutes, add the acetyl ferrocene powder that total amount is 2.76 grams in batches, then fully stir 1h;

[0026] In the second step, the solution obtained in the first step is extracted and washed twice with dichloromethane, and the water phase is adjusted to PH=2 to 3 with strong acid, and a yellow precipitate is precipitated, filtered after cooling, washed twice with water, and the solid obtained by filtering is di Ferrocene formic acid, the calculated yield by weighing is 84%.

Embodiment 3

[0028] In the first step, 60 ml of deionized water and 10 g of sodium hydroxide were added to the reactor and stirred to dissolve to form a sodium hydroxide solution; the reactor was cooled to 30°C with an ice-water bath, and 2 ml of PEG-400 and 16.8 Gram iodine-potassium iodide, add the acetyl ferrocene powder that total amount is 3.22 grams in 40 minutes, then fully stir 1h;

[0029] In the second step, the solution obtained in the first step is extracted and washed twice with dichloromethane, and the water phase is adjusted to PH=2 to 3 with strong acid, and a yellow precipitate is precipitated, filtered after cooling, washed twice with water, and the solid obtained by filtering is di Ferrocene formic acid has a yield of 79.3% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com