Device for pulling out cylinder head fuel injector sleeve

A fuel injector and cylinder head technology, which is applied in the field of engine maintenance tooling, can solve problems such as mixing, fuel injector cover removal, and increased maintenance workload, and achieve the effects of reducing labor intensity, simple structure, and simplified maintenance processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

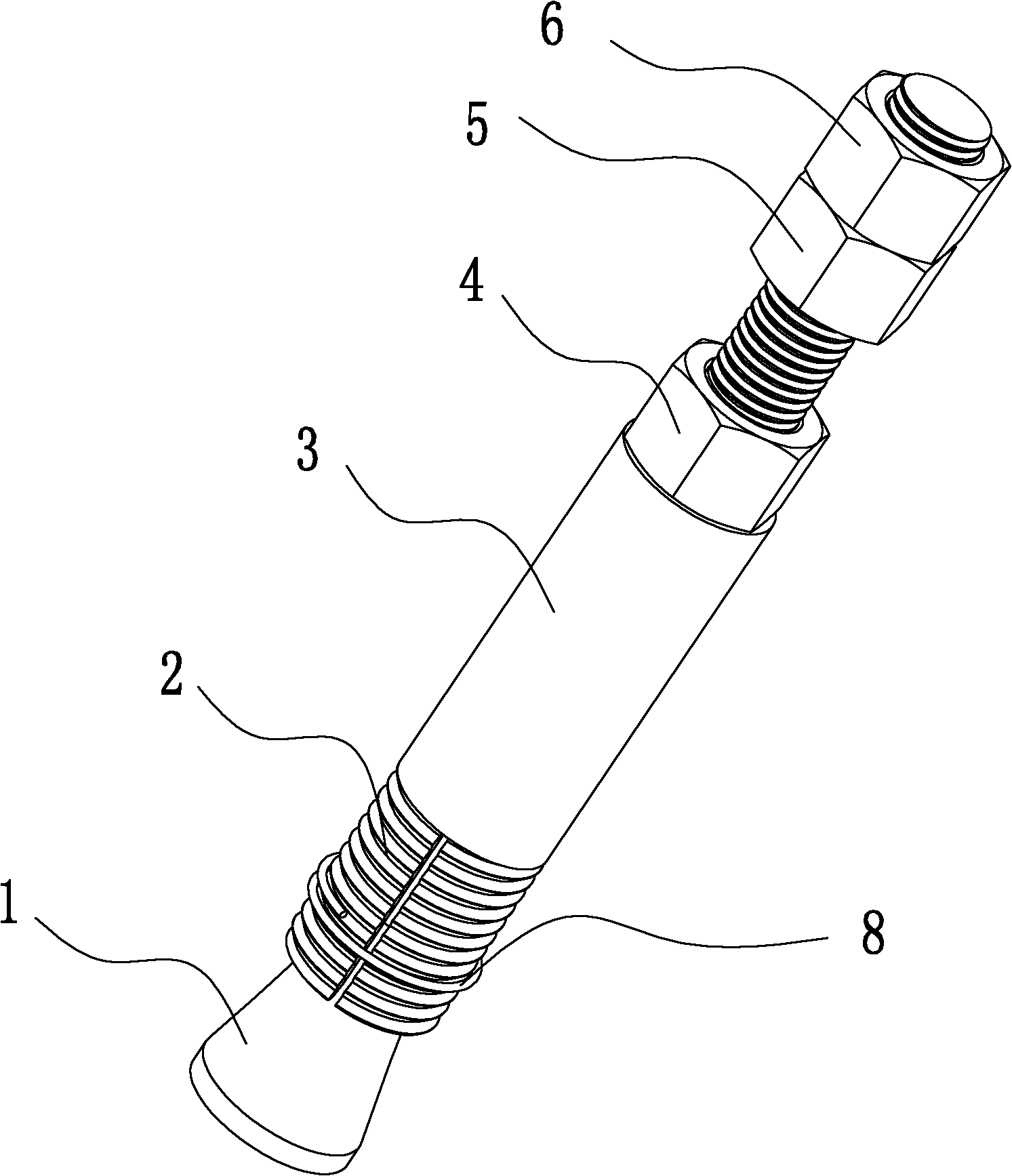

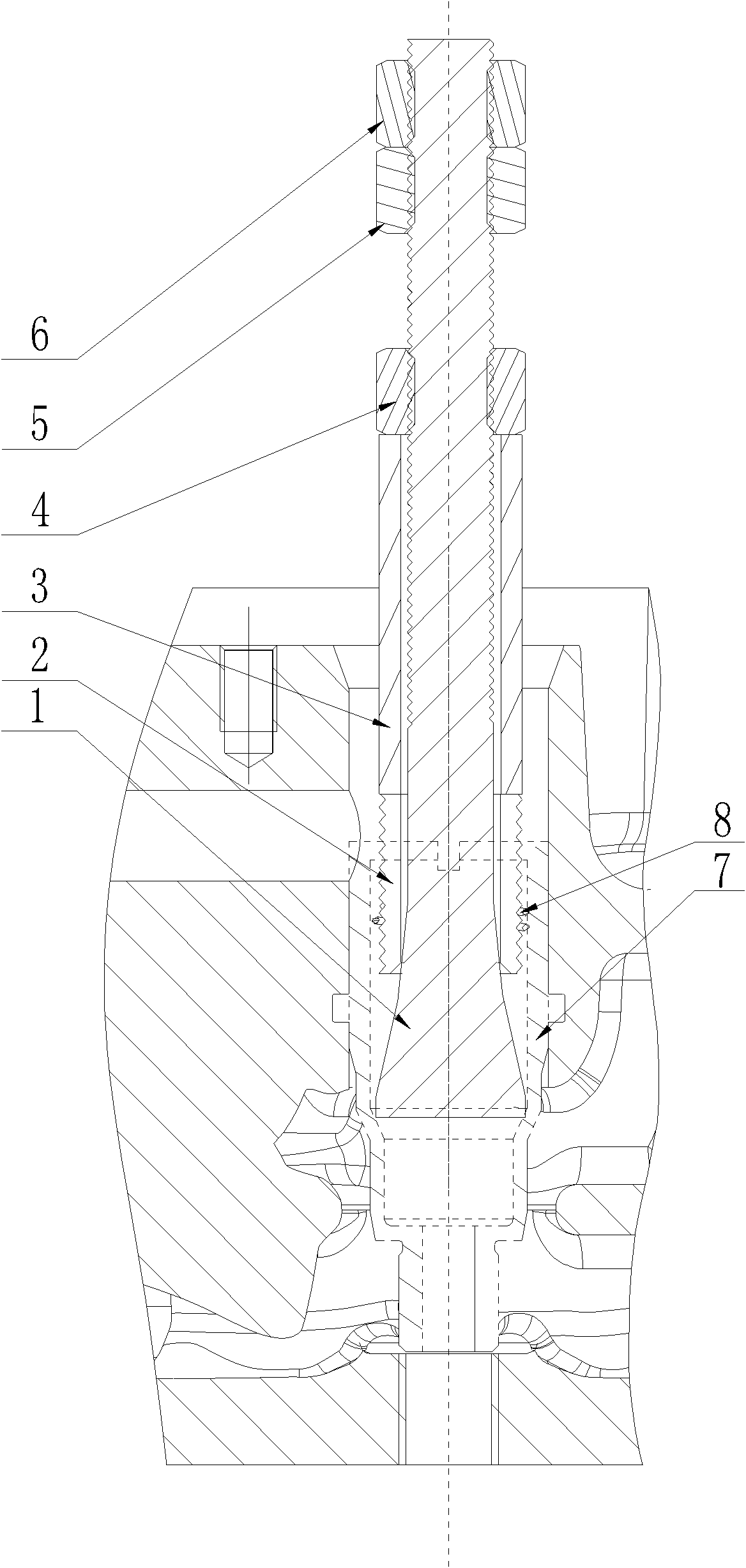

[0013] see figure 1 and figure 2 , a cylinder head injector sleeve pulling device, the pulling device mainly includes a screw 1 with a thread at one end and a conical structure at the other end, the upper part of the tapered end of the screw 1 is sleeved with an expanding sleeve 2, and the expanding sleeve is The upper end screw 1 of 2 is sleeved with a spacer 3, which can slide freely between the spacer 3 and the screw 1. The upper screw 1 of the spacer 3 is equipped with a locking nut 4, and the threaded end of the screw 1 is equipped with a lock nut 4. Two lock nuts (5, 6) are installed. When in use, clamp the lock nut 6 at the upper end with an external tool to prevent the lock nut 4 from rotating synchronously with the screw 1.

[0014] In order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com