Method for manufacturing endless cutting wire for ingot cutting

A manufacturing method and metal wire technology, which is applied in the direction of sawing machine tool manufacturing, manufacturing tools, metal sawing equipment, etc., can solve the problems of reduced cutting performance, weak fixing force, and easy falling off, so as to improve cutting quality and prevent falling off , the effect of strong fixing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

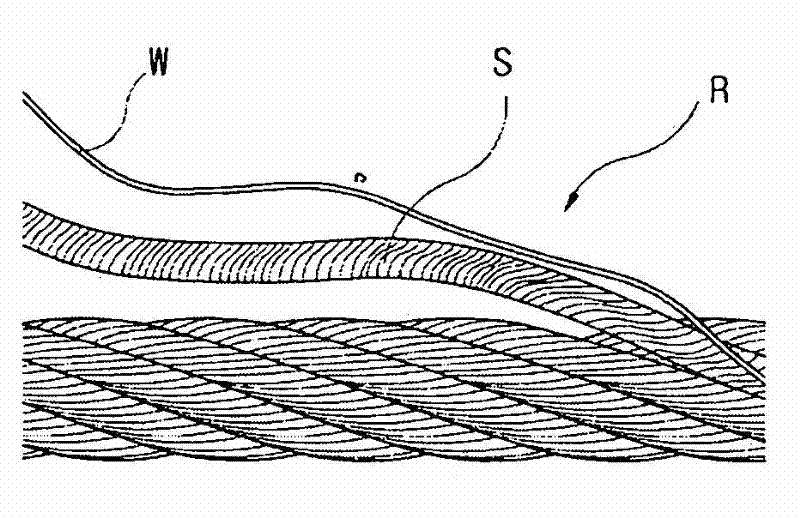

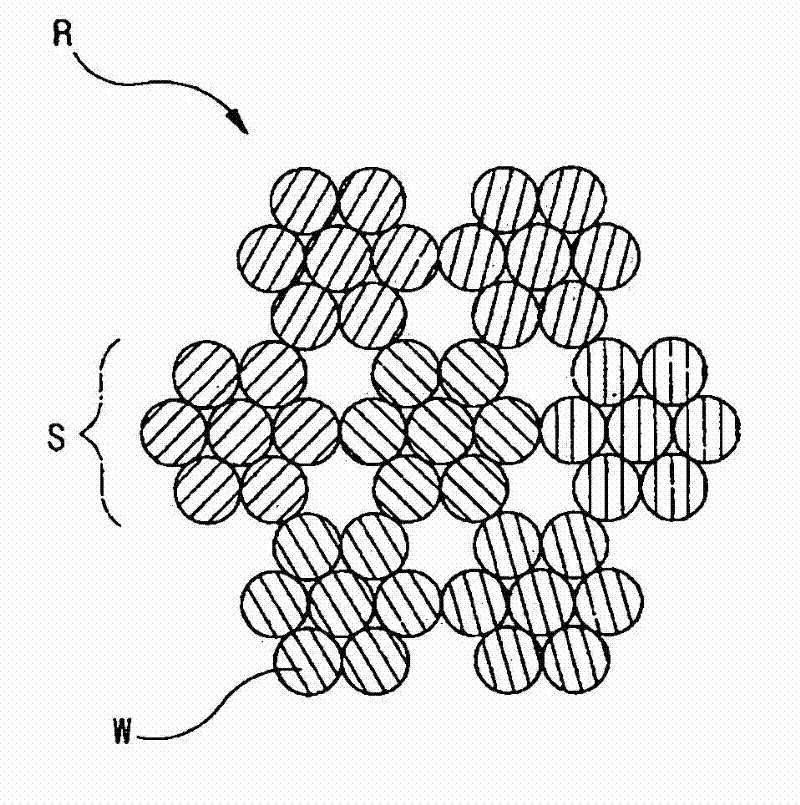

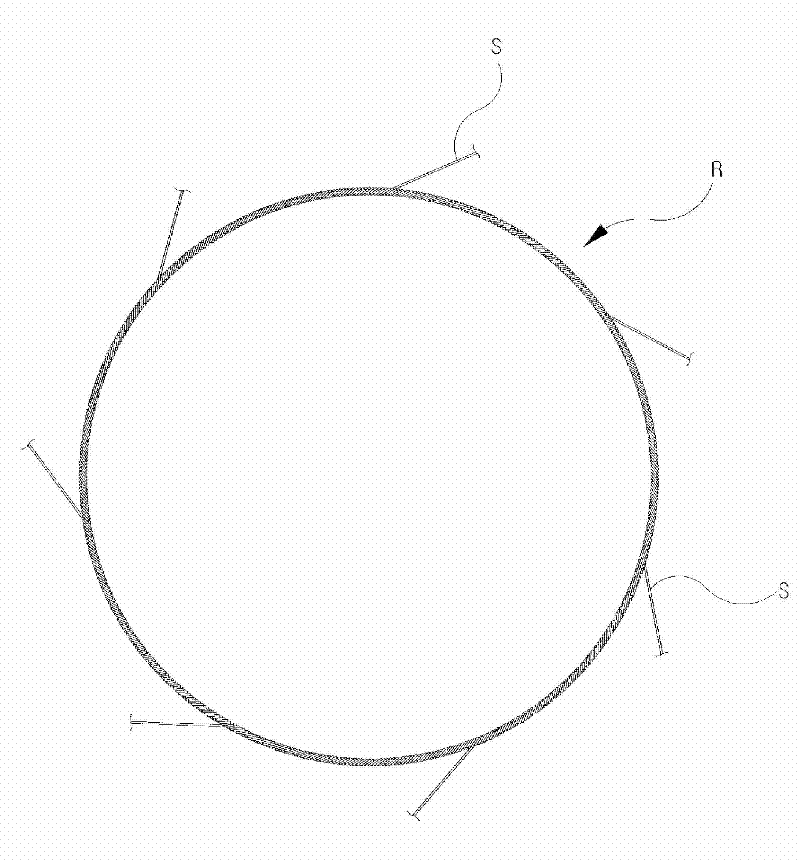

[0028] Dozens of small-diameter metal wires are braided into a twist shape to form a larger-diameter steel strand S, and the above-mentioned steel strands S of a certain length are braided into a large-diameter steel wire rope, so that they are connected as a whole without breakpoints. At the same time as the endless structure, the cutting part (20; hard carbide particles or diamond particles) is fixed on the surface of the above-mentioned steel wire rope, and it can also be used as a high-efficiency ingot when it is tightly coiled between high-speed rotating pulleys. A general ingot-cutting endless cutting wire 10 used for the cutting member. The manufacturing method of the above-mentioned annular cutting wire for ingot cutting includes the following steps: weaving dozens of small-diameter wires into twist-shaped steel strands (S; 0.5 mm or less) of a certain thickness, and preparing at least seven or more After the above-mentioned steel strands of the same length, the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com